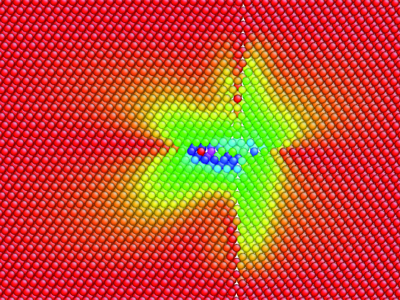

The efficiency of conventional power stations can be increased through the use of new heat and corrosion resistant steels that are able to withstand higher temperatures and steam pressures. Steels with a high chrome content are made more resistant to fracture and creep by aiming for a microstructural design with Z phase precipitation. At the IWM, we investigate the formation of these nitrides using a multi-scale approach that combines atomistic simulations and thermodynamic modeling. This furthers our understanding of the reinforcing mechanisms and enables us to predict material fatigue.

Precipitation in iron and steel

Publications

- Möller, J.J.; Mrovec, M.; Bleskov, I.; Neugebauer, J.; Hammerschmidt, T.; Drautz, R.; Elsässer, C.; Hickel, T.; Bitzek, E., {110} planar faults in strained bcc metals: Origins and implications of a commonly observed artifact of classical potentials, Physical Review Materials 2/9 (2018) 093606 1-16 Link

- Urban, D., High-temperature operation of the components and constructions made from newly developed chromium steels, Chernye Metally 7 (2018) 67-68 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM