Manufacturing Processes

Our understanding of processes and sophisticated simulation techniques enable us to design efficient and safe manufacturing processes. Our services include investigations into the technological development of manufacturing processes for the production of semi-finished products and components with functional properties. This work ranges from powder technology processes, including complex fluid systems, to microfluids, the forming and processing of ductile materials as well as processing techniques for brittle materials and glass forming.

What we offer

- Innovative manufacturing processes for precision contours and functional components with defined property profiles

- Simulation-assisted optimization of the energy and material efficiency of manufacturing processes

- Modeling and simulation of powder technology and fluid dynamic processing stages, simulation methods for generative manufacturing

- Forming process simulations including microstructure development and thermodynamics

- Forming, processing and damage analyses for brittle materials such as glass and silicon

Contact us! Together we'll find a customized solution for the challenges you face.

SimPARTIX:

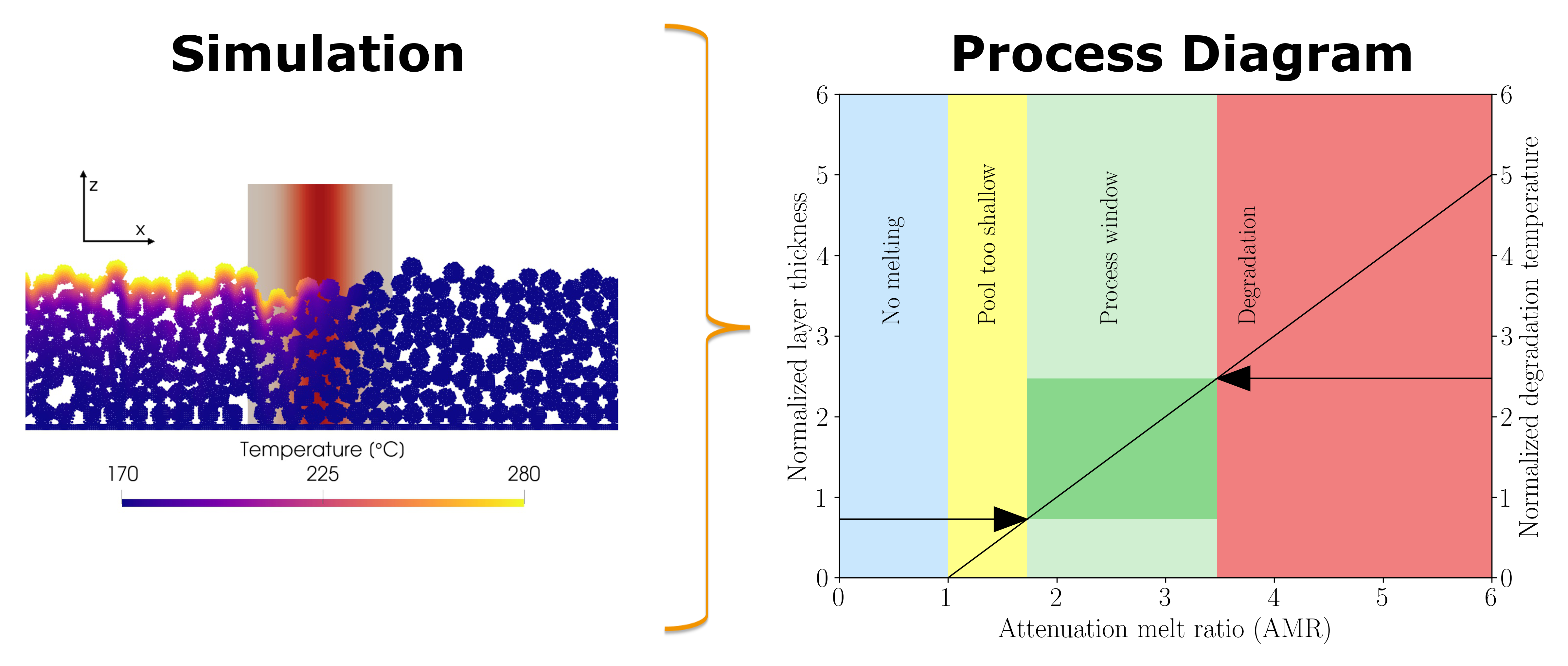

Polymer laser powder bed fusion

The proportion of additively manufactured parts is increasing rapidly in the polymer industry. Nevertheless, the choice of materials for laser powder bed fusion (PBF-LB/P) in particular is very limited compared to other polymer manufacturing processes. A major reason is a lack of knowledge about which material properties are important for the process and how process parameters affect product quality. To address this, Fraunhofer IWM uses its unique software SimPARTIX to link material properties, process parameters and component quality. This enables the development of new materials and high-quality components.

AID4GREENEST:

As one of 10 partners, the Fraunhofer IWM is playing a key role in the EU project AID4GREENEST in making the steel industry more sustainable and developing it in the direction of "green steel".

The AID4GREENEST project encompasses the design of materials, processes and products, as well as product performance. To this end, we are using the potential of artificial intelligence for innovative characterisation methods and modelling tools. Among other things, these should contribute to accelerate development processes in the steel industry, improve material quality and reduce the carbon footprint.

StahlDigital:

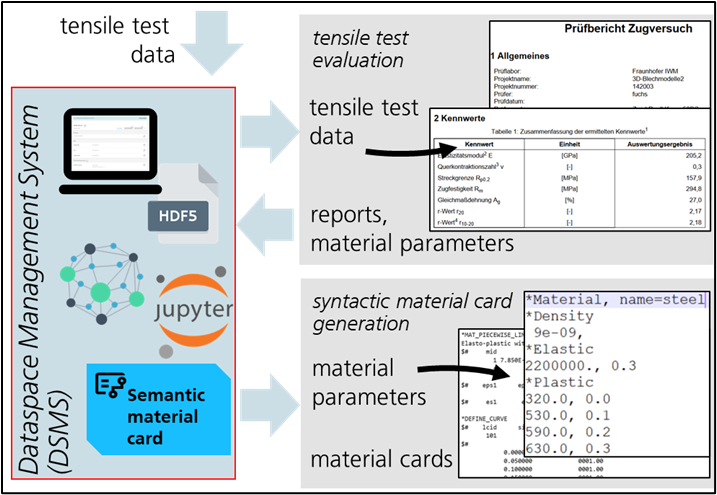

Semantic material cards

Material cards are required for the simulation of processes and components. However, the process to connect test data to validated material cards is time consuming and the quality is not guaranteed.

To this aim, Fraunhofer IWM researchers are harmonizing heterogenous test data on a semantic level in an ontology-aware dataspace. The generalized material card representation enables the export to multiple material card types for different simulation engines. Moreover, it contains all information about the origin of the material model parameters (e.g., provenance of original test data). A proof of concept was successfully demonstrated in September 2023 on behalf of the project StahlDigital, which is part of the initiative MaterialDigital.

PeroTec:

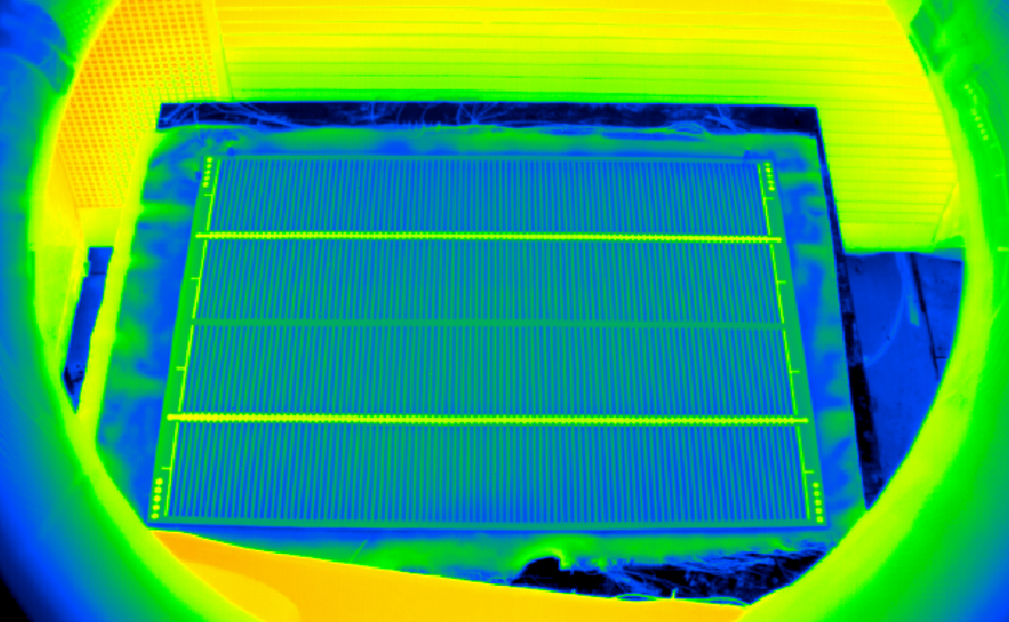

Joining processes for the production of perovskite solar modules

Photovoltaic solar modules, whether based on silicon or perovskite, require long-term stable, airtight and moisture-proof encapsulation. In the PeroTec project, we are developing a long-term stable encapsulation for perovskite solar cells based purely on glass.

We are using our in-depth understanding of the residual stresses and softening behaviour of float glass to achieve long-term stable and gas-tight sealing using glass solders. The main challenge is to generate a gap of a constant 20 µm between the glass plates over the entire module surface, which is then filled with perovskite crystals. The structured solder layer electrically separates individual cells from each other; conductor layers applied to the glass interconnect the cells to form a module. In our pilot plants, we can produce and characterise modules with an active area of up to one square meter.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM