Crash Dynamics

Modern CAE-assisted developments require characteristic material parameters that correspond to specific load situations in order to produce designs and assess safety. Crash-relevant material values related to the strain rate or load speed are also needed to determine vehicle crash safety or accident-related impact loads on transportation containers: we determine the values for different materials and joins via high-speed tests that involve high-speed video and infrared cameras as well as optical evaluation processes. Our component crash tests are used to validate numerical simulations and provide conclusive assessments.

- Vehicle safety and misused/crashed lightweight designs: crash-like material characterization and identification of crash parameters as the basis for crash simulation material cards as well as component crash tests for verification and assessment purposes

- Container safety on impact: impact load tests on samples similar to the component or the components themselves including analysis and assessment

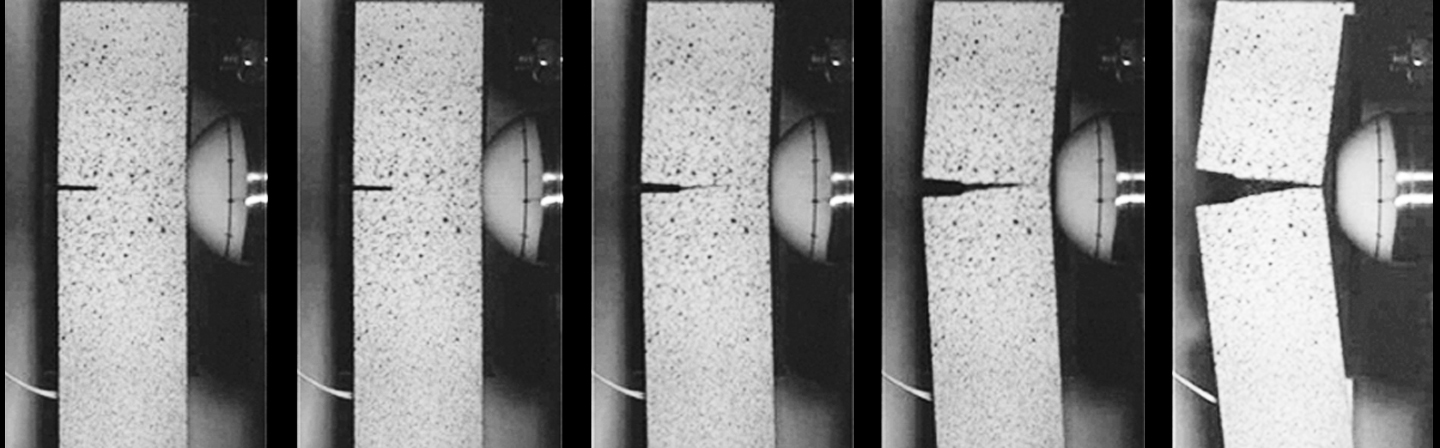

- Plant safety in the event of an accident/breakdown (fracture dynamics): fracture dynamic material characterization at high crack stress rates for the analysis of thick-walled, cracked structures

- Optimizing high-speed forming processes: dynamic Nakajima deep drawing tests with detailed optical 3D deformation analyses using high-speed video cameras and ARAMIS in order to determine forming limit diagrams

- Development of testing methods with which to characterize materials and joins under complex single and multi-axial loads

- The use of modern high-speed metrology such as high-speed infrared measurements and 3D high-speed video analysis of rapidly changing strain fields

- Characterization and assessment of lightweight constructions, joins and innovative materials on impact and in crash situations

Contact us! Together we'll find a customized solution for the challenges you face.

How to work with the Fraunhofer IWM

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM