The influence of production-related defects on the strength behavior of cast steel components

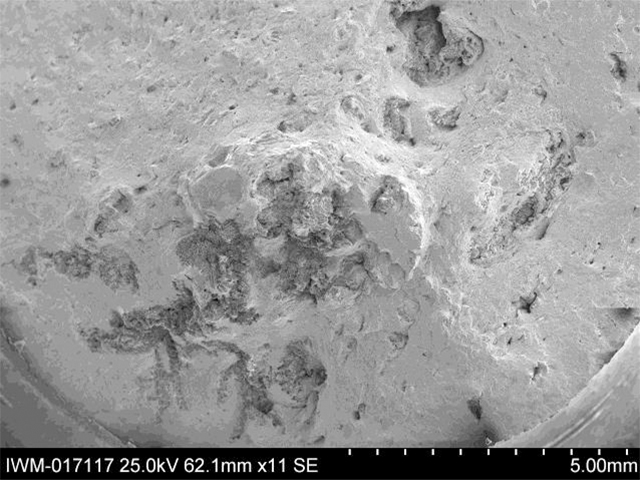

The evaluation of faults in cast steel components is a vital part of strength calculation. Using the examples of materials G20Mn5 and G22NiMoCr5-6, a validated assessment concept was provided in the course of an Industrial Collective Research (IGF) project. Critical to this project were the validation of different non-destructive test methods, strength tests of samples with defects, as well as damage and fracture mechanical analyses of the experiments. The samples, which were examined using different NDT-techniques (ultrasound, expanded ultrasound procedures, CT), provided consistent results. The strength tests showed that, despite some bigger defects, the defect-free material only exhibited ductile failure in areas of stability, whereby breaking elongation decreases with increasing defect size. Fracture mechanics evaluation has proven to be an efficient concept. Fracture mechanical calculations provide conservative results and confirm that all samples with defects can support high strain loads surpassing yield stress. Furthermore, both tested materials’ fracture resistance was much higher than, for example, the conservative figures stated in FKM-guidelines.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM