Fatigue and fracture mechanics assessment of weld joints

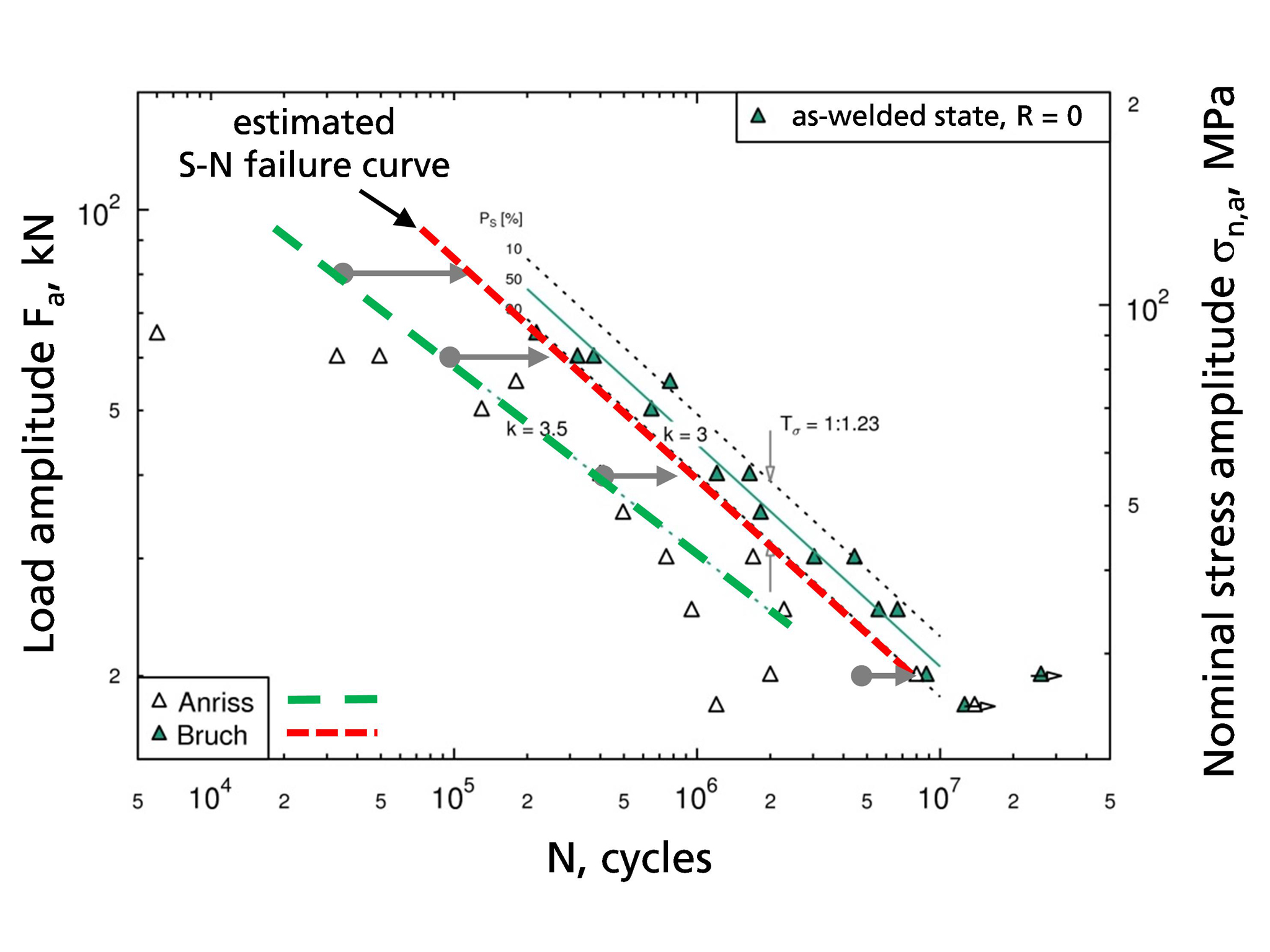

By combining cyclic plasticity models, numerical welding process simulation and fatigue and fracture mechanics models, the lifetime of a welded component can be described realistically. In the following example, welding residual stresses and their stabilized state were determined by fatigue tests. In corresponding experiments (Fraunhofer LBF), a significant difference between the crack-initiation- and fracture-Wöhler-curves was found which can be very well described by means of fracture mechanics calculations. The calculations were based on crack propagation curves of the investigated material S460NL, an initial crack with a depth of 0.2 mm and a suitable fracture mechanics model implemented in IWM VERB.

As part of the DFG-AiF cluster project IBESS »Integral fracture mechanics determination of the fatigue strength of welded joints«, Fraunhofer IWM has developed a fracture mechanics substitute model for the formation of cracks on the basis of real micromechanical structures to determine initial crack sizes for macroscopic fracture mechanics lifetime predictions. This approach includes the:

- numerical simulation of crack initiation on a microstructure scale,

- generation of a polycrystalline 3D microstructural model featuring crack initiation at the free surface,

- FE-analyses under cyclic loading,

- validation via fatigue testing with micro specimens,

- determination of the initial crack size distribution.

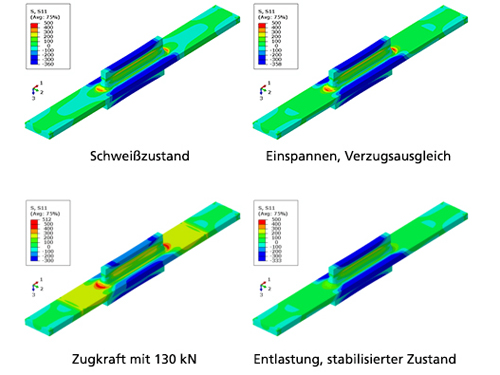

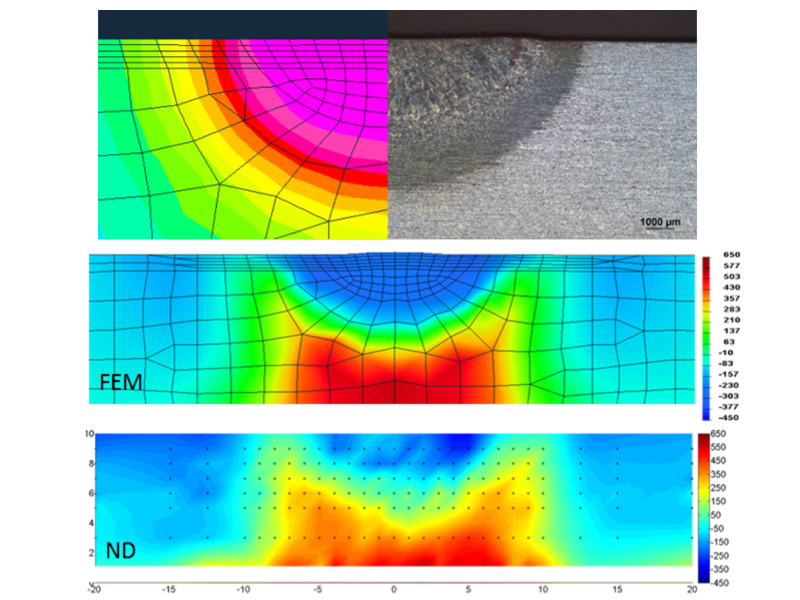

For the assessment of the fatigue strength of welded joints, a realistic estimation of the damaging effect of welding residual stresses are of fundamental importance. A necessary element is the evaluation of the welding residual stress field and its possible degradation under mechanical loading. By means of validated numerical evidence the influence of residual stresses on the structural integrity may be quantified and the design of fatigue-resistant light-weight components facilitated.

For this purpose, we develop suitable material models describing the material behavior during the welding process and the resulting residual stress and distortion field precisely. Whether the residual stress field causes damage depends strongly on its behavior during operation. A stable welding residual stress field can affect the material-related fatigue strength and the service lifetime of components and structures.

- Renken, F.; von Bock und Polach, R.U.F.; Schubnell, J.; Jung, M.; Oswald, M.; Rother, K.; Ehlers, S.; Braun, M., An algorithm for statistical evaluation of weld toe geometries using laser triangulation, International Journal of Fatigue 149 (2021) Art. 106293 Link

- Schubnell, J.; Ladendorf, P.; Sarmast, A.; Farajian, M.; Knödel, P., Fatigue performance of high- and low-strength repaired welded steel joints, Metals 11/2 (2021) Art. 293, 20 Seiten Link

- Beckmann, C.; Kennerknecht, T.; Preußner, J.; Farajian, M.; Luke, M.; Hohe, J., Micromechanical investigation and numerical simulation of fatigue crack formation in welded joints, Engineering Fracture Mechanics 198 (2018) 142-157 Link

- Hemmesi, K.; Farajian, M., Numerical welding simulation as a basis for structural integrity assessment of structures: Microstructure and residual stresses, Residual stress analysis on welded joints by means of numerical simulation and experiments; Ferro, P. (Ed.); IntechOpen Limited, London, UK (2018) 29-47 Link

- Varfolomeev, I.; Moroz, S.; Siegele, D.; Kadau, K.; Amann, C., Study on fatigue crack initiation and propagation from forging defects, Procedia Structural Integrity 7 (2017) 359-367 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM