Forming Processes

Our experience with the latest materials science and materials engineering findings enables us to optimize forming tools and processes, while numerical simulations facilitate the avoidance of trial and error loops. We develop material models that describe material behavior and determine relevant material and process parameters.

What we offer

- Simulation of sheet and bulk metal forming processes (e.g. rolling, deep drawing, extrusion)

- Development of multiscale material models

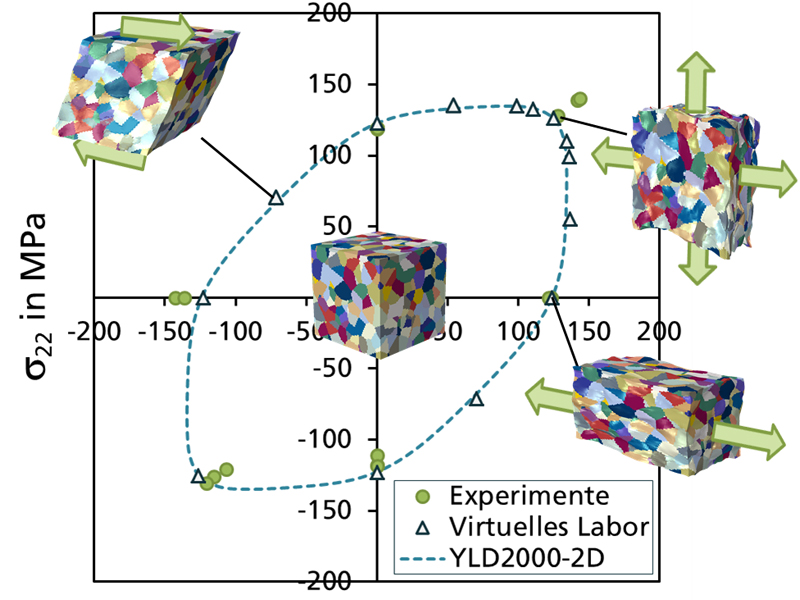

- Determination of material properties via the "Virtual Laboratory“

- Machine learning for forming processes

- Material testing

- Thermomechanical material testing

- Thermophysical laboratory

- Sheet metal testing laboratory

Contact us! Together we'll find a customized solution for the challenges you face.

The latest news from the group "Forming Processes"

Microstructure evolution in extrusion (01/22)

Functional surfaces through adiabatic high-speed processes: Microstructure, mechanisms, and model development — FUNDAM³ENT (DFG-FOR 5380)

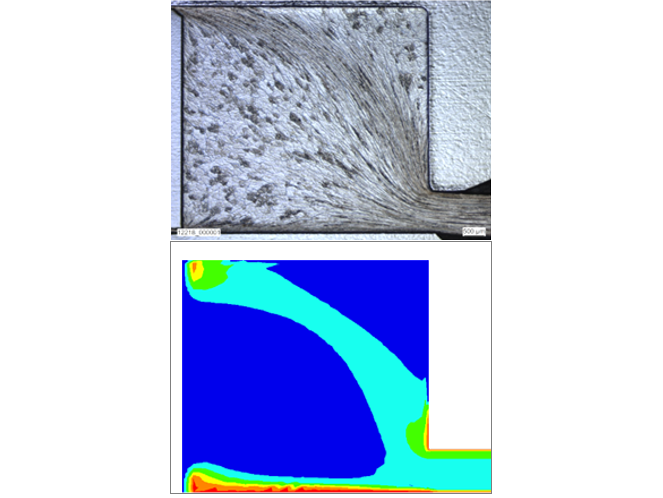

High-speed blanking (HSB) is an economically and ecologically interesting alternative to conventional cutting processes such as normal, fine or laser cutting. Especially for high-strength and ultra-high-strength steels, as well as light metals, HSB holds great potential regarding the generation of blanked surfaces that can be used directly as functional surfaces without further mechanical, thermal or thermo-chemical post-processing steps, which is attributed to the adiabatic shear band (ASB) formation. The FUNDAM³ENT research group is dedicated to investigating the material- and process-specific factors influencing the formation of ASB in HSB within an interdisciplinary network. The research group consists of six individual research institutes that will support each other comprehensively for the duration of the project. The group comprises three research institutes focusing on materials and materials simulation — Fraunhofer IWM as well as LWW and WOT (TU Chemnitz) — and three research institutes focusing on process and process simulation — IUL, Fraunhofer IWU and UTG (TU München). The focus of the Fraunhofer IWM subproject is the development of numerical modelling approaches to describe the formation and propagation of ASB in HSB as well as the microstructure evolution within the ASB. Taking into account experimental data, a fundamental understanding of the mechanisms relevant for ASB formation will be developed by linking thermo-mechanical and microstructural simulation approaches which will further support process optimization for the investigated materials (5xxx series Al alloys and 20MnB5).

New Industrial Collective Research project on microstructure evolution in extrusion

A new Industrial Collective Research (IGF) project on modeling microstructure evolution in extrusion processes started at Fraunhofer IWM in collaboration with the Institute of Forming Technology and Lightweight Components (IUL) at TU Dortmund University. The objective is to develop a practical approach for predicting the grain structure evolving during extrusion processes by means of numerical simulations. For application, the goal is to provide a calculation tool predicting the microstructure quality of extruded products in order to enable faster adaptation of the processing conditions to new materials or changed process parameters.

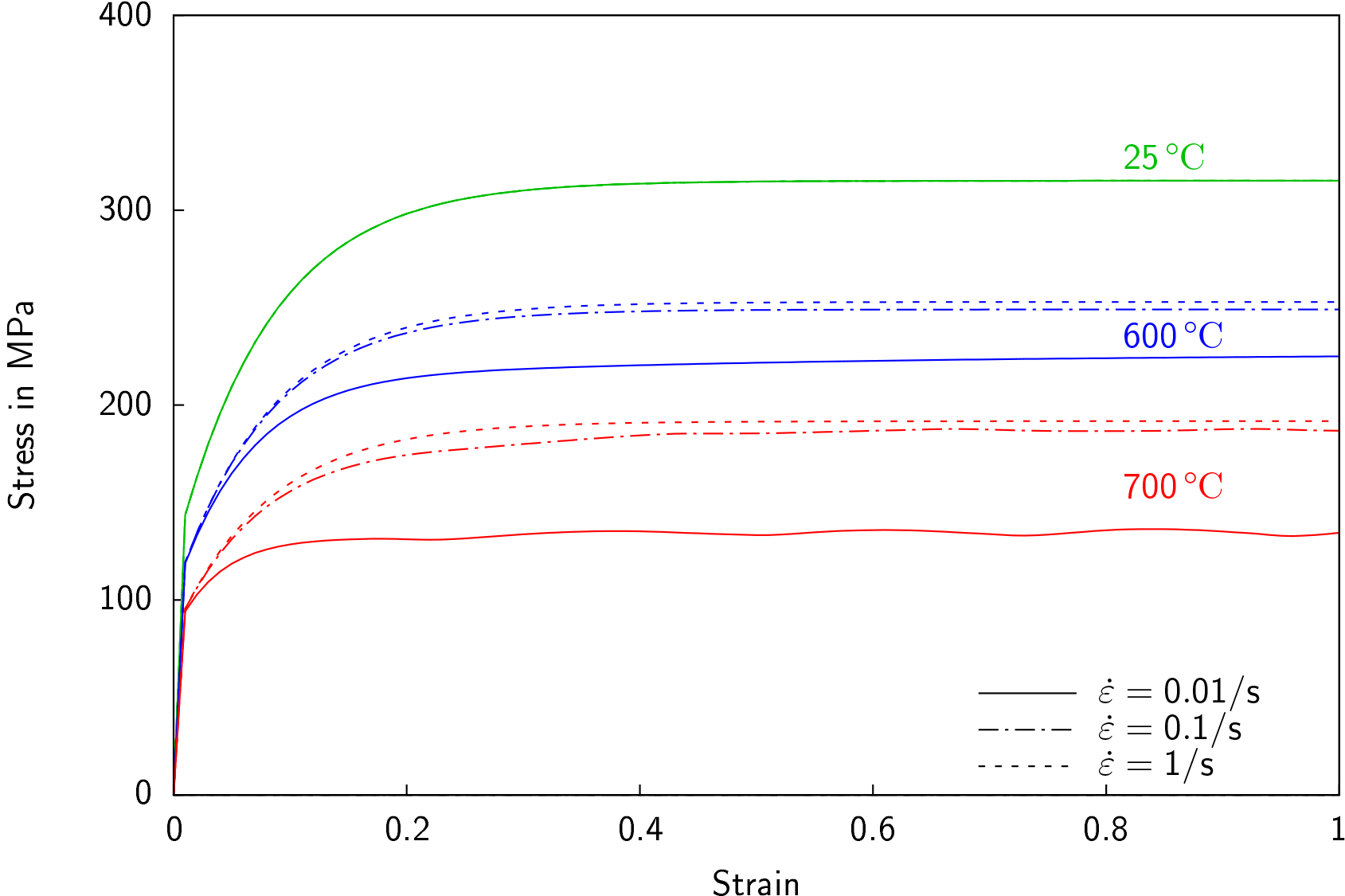

The project includes a comprehensive thermo-mechanical testing schedule on aluminum alloys of practical relevance as well as metallographic analyses of the specimens. Hot compression tests under various conditions are carried out at the Fraunhofer IWM using the Gleeble 3150 thermo-mechanical simulator, while a laboratory-scale extrusion press is available at the IUL.

We use the experimental results to calibrate the thermodynamically consistent mean-field model for microstructure evolution developed at Fraunhofer IWM. Next, we will make use of the model to simulate a large number of different thermomechanical tests. Considering the results from these virtual tests, the experimental database will be considerably expanded.

Finally, based on the expanded database, we will calibrate a physically motivated and numerically very efficient material model. The efficient model will be implemented as a material routine for commercial finite element software. We will thus provide a fast and efficient tool to predict the development of the grain structure during extrusion of aluminum profiles.

Further information on modeling microstructure evolution by the group Forming Processes

Dr. Lukas Kertsch

Telephone +49 761 5142-479

Send email

Dr. Maksim Zapara

Telephone +49 761 5142-352

Send email

DFG project „Taylored material properties through microstructure optimization“

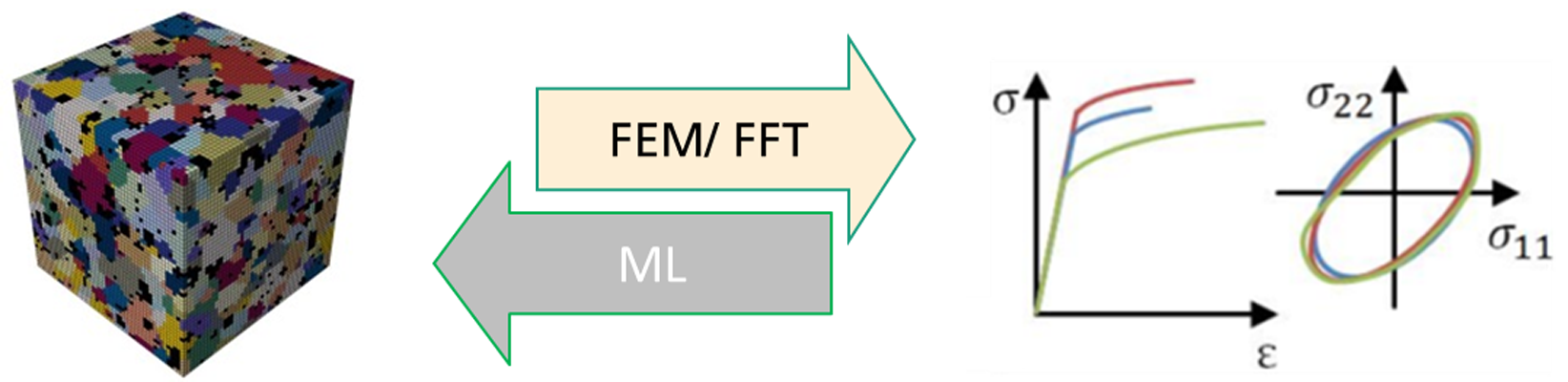

DFG project „Taylored material properties through microstructure optimization: Machine learning for modeling and inversion of structure-property relations and their application on sheet metal“ started

The derivation of processing control actions for the production of materials with certain, desired properties is the "inverse problem" of the causal chain "process control" - "microstructure instantiation" - "material properties". The main goal of the proposed project is the creation of a new basis for the solution of this problem by using modern approaches from the field of Machine Learning.

The inversion will be composed of two explicitely separated parts: "Property-Structure-Mapping" and "structured-guided optimal process control".

The focus of the project lies on the investigation and development of methods which allow an inversion of the structure-property-relations of materials, which are relevant in the industry. This inversion is the basis for the design of microstructures and for the optimal control of the related production processes. Another goal is the development of optimal control methods yielding exactly those structures which have the desired properties. The developed methods will be applied to sheet metals within the frame of the project as a proof of concept.

The goals include the development of methods for inverting technologically relevant "Structure-Property-Mappings" and methods for efficient microstructure representation by supervised and unsupervised machine learning.

Adaptive processing path-optimization methods, based on reinforcement learning, will be developed for adaptive optimal control of manufacturing processes.

We expect that the results of this work will lead to an increasing insight into technological relevant process-structure-property-relationships of materials. The instruments resulting from the project will also promote the economically efficient development of new materials and process controls.

Grey-box models: expert knowledge in machine learning

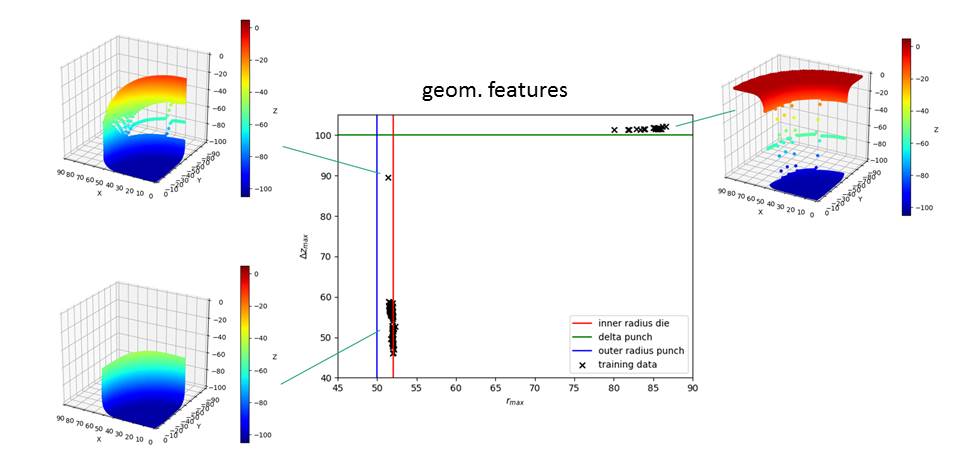

Project Grey-box models: integrating expert knowledge within machine learning

The main issue of project Grey-Box models is to improve machine learning methods (black-box models) by integrating domain knowledge, using for example deterministic models (white-box models). Grey-box models aim especially at industrial applications, as there are typically only few significant (distributed over the space of process parameters) data available, whereas the processes themselves are relatively well known. During the project, we will work on three use-cases focusing on material science: automatic crack surface detection in microstructural images, surrogate modeling of deep drawing processes and the identification for material model parameters using neural networks.

DFG Project on Simulating Hot Forming

DFG Project on Simulating Hot Forming and Heat Treatment Enters Second Round

Within the Priority Program 1713 of the German Research Foundation (DFG), we are working on a novel simulation tool for hot forming and heat treatment of metallic materials. Our approach links the thermomechanical material behavior and microstructure evolution using a comprehensive thermodynamic framework. This allows us to efficiently represent elastic-plastic material behavior, recovery, recrystallization, grain coarsening, texture evolution and precipitation as well as the related hardening and softening processes. After a successful first project phase, a second phase of three years duration was granted and started in December 2017.

Lukas Kertsch

Telephone +49 761 5142-479

Send email

TWIP-Steel simulation for sheet metal forming

TWIP-steel features a tensile strength of approx. 1000 MPa with a breaking elongation of 40-50 %. By using TWIP steels, both the energy absorption of components and the structural safety of the vehicle can be significantly improved. The strength of this material allows for a reduction of the sheet thickness used in components and contributes to a more efficient use of resources. Scientists at the Fraunhofer IWM have developed an appropriate material model so that the mechanical properties of TWIP steel can be accurately described. An essential characteristic of this model is the physically based description of microstructural properties and especially the development of the twin volume fractions depending on deformation and state of stress.

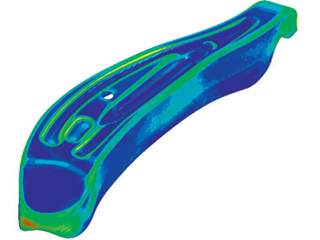

Process chain simulations

The entire process chain can be virtually described through the linking of either very similar or quite different simulation methodologies. At the Fraunhofer IWM we develop methods for the linking of subsequent process steps: cold rolling simulations realized via the finite element method (FEM) are combined with heat treatment descriptions. The ensuing results are then used in microstructure simulations to predict macroscopic, mechanical characteristics which are incorporated into material models for component forming simulations. This enables us to test the influence of individual process parameters on material properties.

The "Virtual Lab"

The "Virtual Lab" is a simulation tool for the numerical determination of macroscopic material properties which takes the microstructure into account. Data produced through our "Virtual Lab" can be used in exactly the same manner as experimental data and is especially applicable to the complex material models which are required when working with modern, high-strength sheet metal materials. These complex material models utilize many parameters which can be identified by the additional data obtained from the "Virtual Lab".

More about the virtual determination of parameters for sheet metal forming simulations

University lectures

Dr. Dirk Helm:

Forming technology process simulation

at the Karlsruhe Institute of Technology KIT

Continuum Mechanics I/II

at the University of Freiburg

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM