Assessment of the load-carrying capacity of a spotwelded metal sheet with a softened heat affected zone

Spotwelded metal sheets with softened heat affected zone

The spotwelding process is still the most commonly used joining process for body-in-white manufacturing. More and more, high-strength steels are being utilized and welded. However, high-strength steels such as 22MnB5 and HCT980C will form a softened heat affected zone around the spotweld due to the heat treatment during the welding process. This softened heat affected zone has different geometrical dimensions depending on the welding process parameters and reduces the load-carrying capacity of the metal sheet.

The tool presented on this website serves to assess the load-carrying capacity of a metal sheet with a softened heat affected zone. The analytical model which is implemented in this tool was developed as part of an AiF-project.

Tool for assessment of the load-carrying capacity of a spotwelded metal sheet

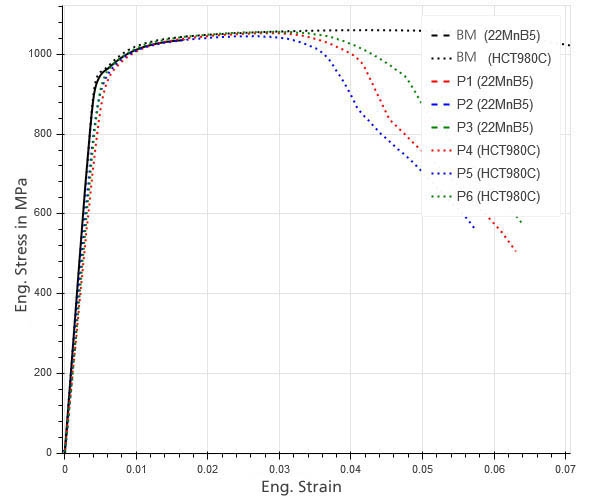

Using the presented tool a stress-strain curve of a spotwelded tensile specimen under uniaxial quasi-static loading and thereby the load-carrying capacity of a specimen can be assessed. Generally costly FEM-simulations have to be modeled, calculated and evaluated in order to determine the behavior for this kind of tensile test. The presented tool uses an analytical model which is based on physical relations. The tool allows the calculation of a stress-strain curve with few mouse clicks. Moreover it is easily possible to examine relations between spotweld geometry and different materials using the sliders.

Start the SpotWeld tool with the following link:

https://spotweld-eng.herokuapp.com/spotweld-eng. (Please wait a few moments to allow the tool to fully load.)

How to use the SpotWeld tool

The input fields can be used to specify the spotweld geometry and material used. Moreover there is the possibility to add experimental data for various test cases to the stress-strain diagram. The experimental data is explained under test cases.

Geometry: For calculation of the load-carrying capacity the geometric dimensions of the spot weld are needed. Using the sliders, spotweld radius and width of the softened heat affected zone can be modified. Moreover the sheet thickness can be varied. The width and height of the specimen are fixed at 16 mm and 30 mm respectively.

Material: The engineering stress-strain curve of the base material needs to be provided in tabular form. The curves for 22MnB5 and HTC980C are integrated in the tool. Additionally data on the material of the softened heat affected zone is needed. For the material of the fusion zone no information is needed. The same material as for the base metal is assumed.

Experimental Data: The stress-strain curve for the base material can be added to the diagram for comparison. There are three additional experimental curves for the materials 22MnB5 and HTC980 for sheets with varying spotweld geometries.

Test cases for validation of the analytical model

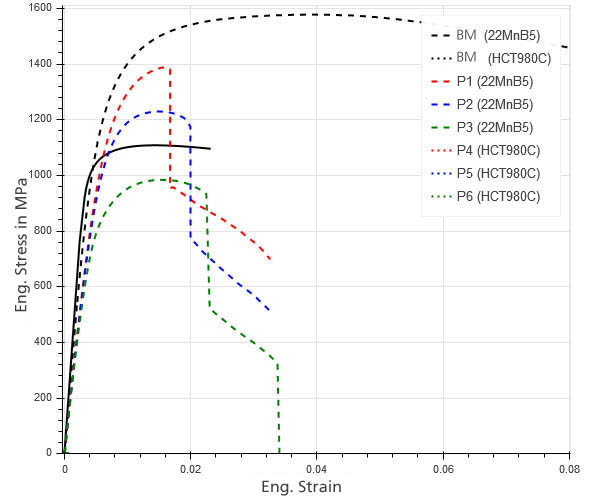

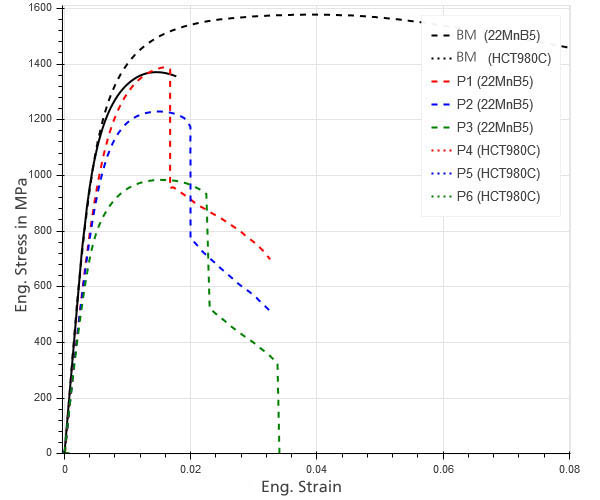

The complex phase steel HTC980C and press-hardened steel 22MnB5 are widely used for body-in white manufacturing. For these materials, experiments have been conducted in order to validate the analytical calculation method. Spotwelded sheets were produced using varying welding process parameters. The resulting spotweld geometries are listed in the table below.

The experimental data can be added to the diagram.

Test cases for 22MnB5

| P1 | P2 | P3 | |

| Width of SHAZ bSHAZ | 0,6 mm | 1,3 mm | 2,9 mm |

| Spotweld radius RSW | 4,4 mm | 5,9 mm | 7,9 mm |

| Sheet thickness t0 | 1,2 mm | 1,1 mm | 1,1 mm |

The tensile strength predictions for the different spotwelded sheets align themselves well with the experimental results. Only the spotweld geometry obtained by welding process parameter P3 has a higher deviation than the experiment. For spotwelds exhibiting a softened heat affected zone considerably larger than the sheet thickness (bSHAZ >> t0), the analytical model loses its validity.

Test cases for HCT980C (also CP1000)

| P4 | P5 | P6 | |

| Width of SHAZ bSHAZ | 0,5 mm | 0,5 mm | 0,5 mm |

| Spotweld radius RSW | 3,5 mm | 4,0 mm | 4,5 mm |

| Sheet thickness t0 | 1,2 mm | 1,2 mm | 1,2 mm |

The produced SHAZ-widths are considerably thinner than in 22MnB5. The welding process parameters show little variation in SHAZ-width and spotweld radius. This is reflected in the experimental results which also show little variation. This relationship is accurately reproduced using the SpotWeld tool. The instability criterion of the analytical model is not satisfying for this material. The strain at failure is highly underestimated.

Acknowledgments

The IGF research project “Charakterisierung und Modellierung der Beeinflussung des Bauteilverhaltens durch Erweichungszonen an Schweißpunkten höchst- und ultrahochfester Stähle unter Crashbelastung“, 17991 N (FOSTA P1018) by Forschungsvereinigung Stahlanwendung e.V. (FOSTA), Sohnstraße 65, 40237 Düsseldorf, Germany, is funded by the AiF under the program for promotion of industrial research (IGF) by the Federal Ministry of Economics and Energy based on a decision of the German Bundestag.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM