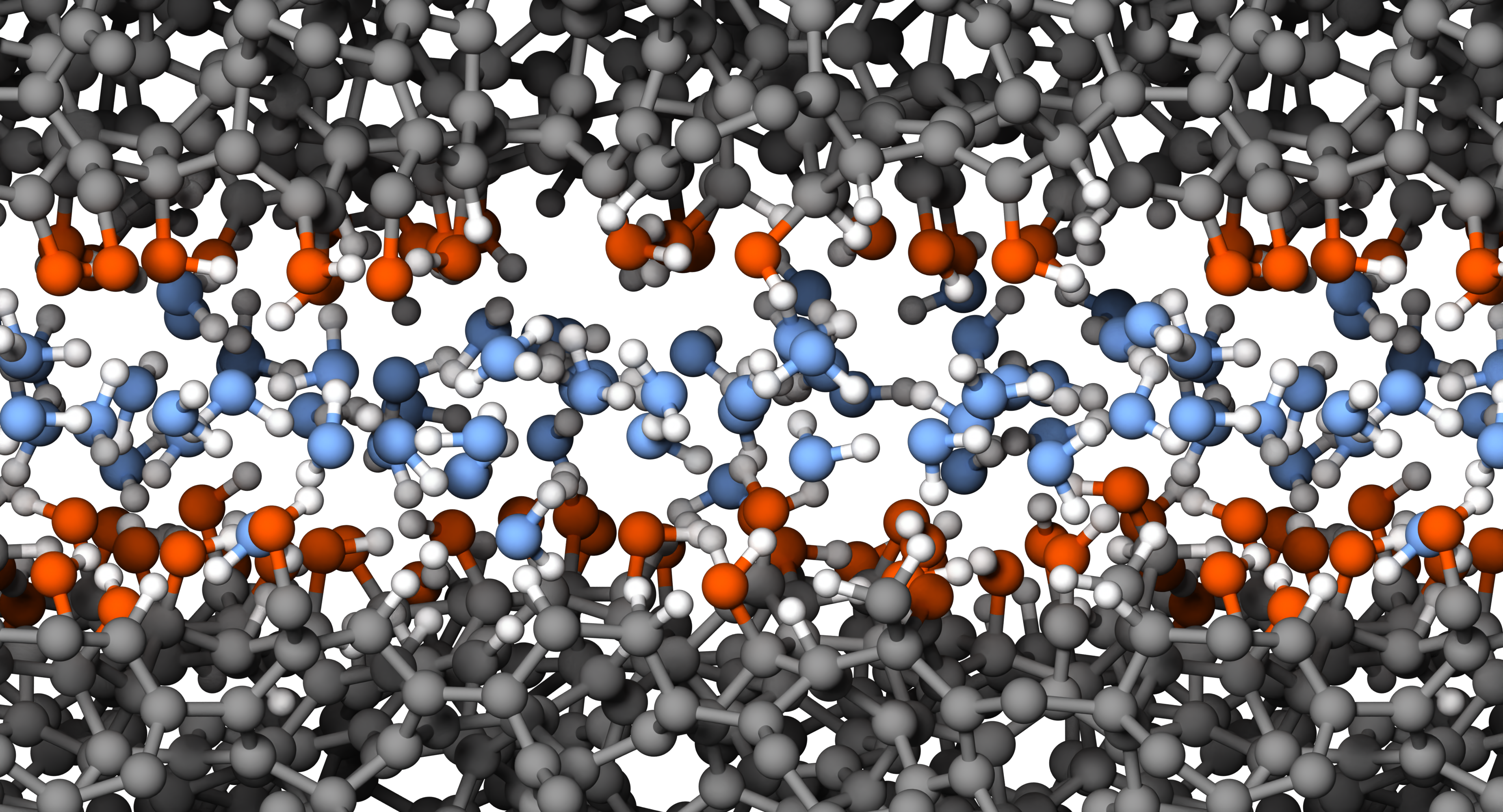

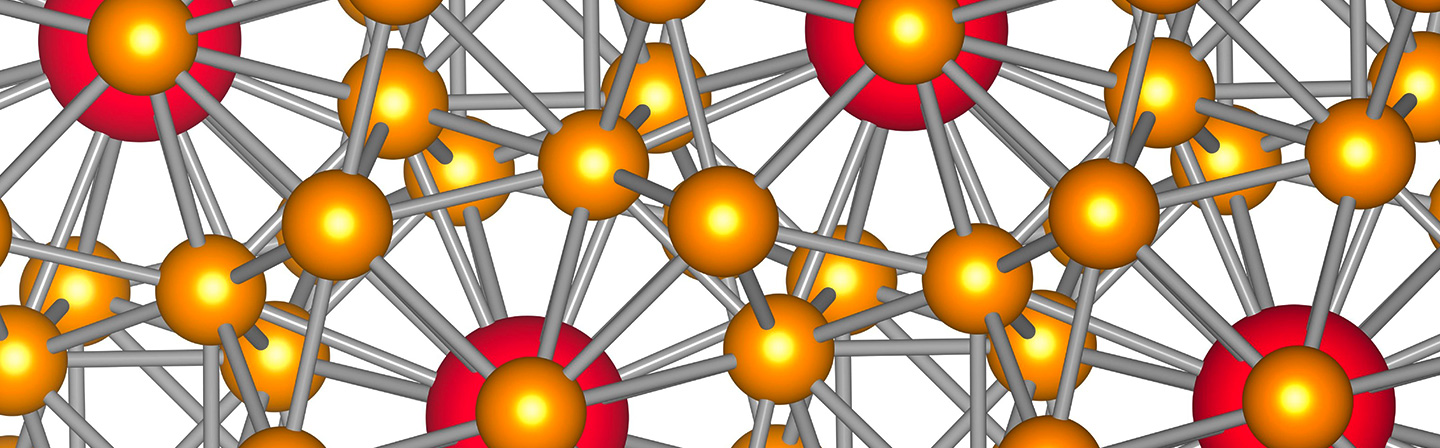

Sustainable solutions for the optimized use of material properties and new material functions

The Fraunhofer IWM is a research and development partner for industry and public contracting bodies concerning the topics of component and systems reliability, safety, durability and functionality. The Fraunhofer IWM’s »mechanics of materials« approach is used to identify weaknesses and defects in materials and components, determine their causes and develop solutions that lead to the safer use of components as well as the development of functional materials and resource efficient manufacturing processes.

Contact Us and together we'll find a customized solution for the challenges you face.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM