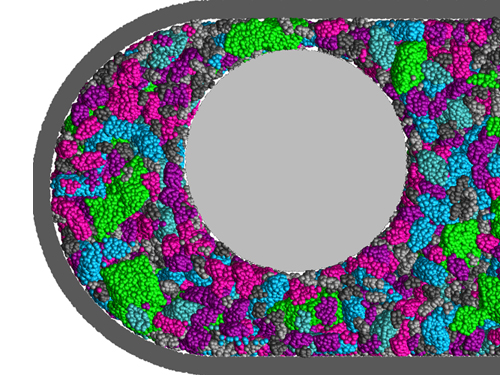

Particle-based simulation methods are used and further developed to simulate the manufacturing processes with particle materials, liquids or suspensions. The discrete element method (DEM) describes the morphology, interaction and dynamics of individual grains. When combined with dissipative particle dynamics (DPD), it is well suited for the simulation of suspensions, such as those used as an abrasive in silicon wafer wire-sawing. Fluids with complex rheology can be described with the aid of smoothed particle hydrodynamics (SPH). Particle-based simulation methods can thus be considered a complement to the continuum-mechanical process and component simulation using the finite element method (FEM). Their use is particularly useful if a process is dominated by the granular or fluidic nature of a material.

SimPARTIX is an innovative and powerful simulation tool for modeling the dynamics of granular materials and complex fluids on the basis of particles. Through analysis and high-resolution 3D visualization of simulations, we can achieve in-depth insights into the process dynamics.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM