Applied R&D regarding high-performance ceramics

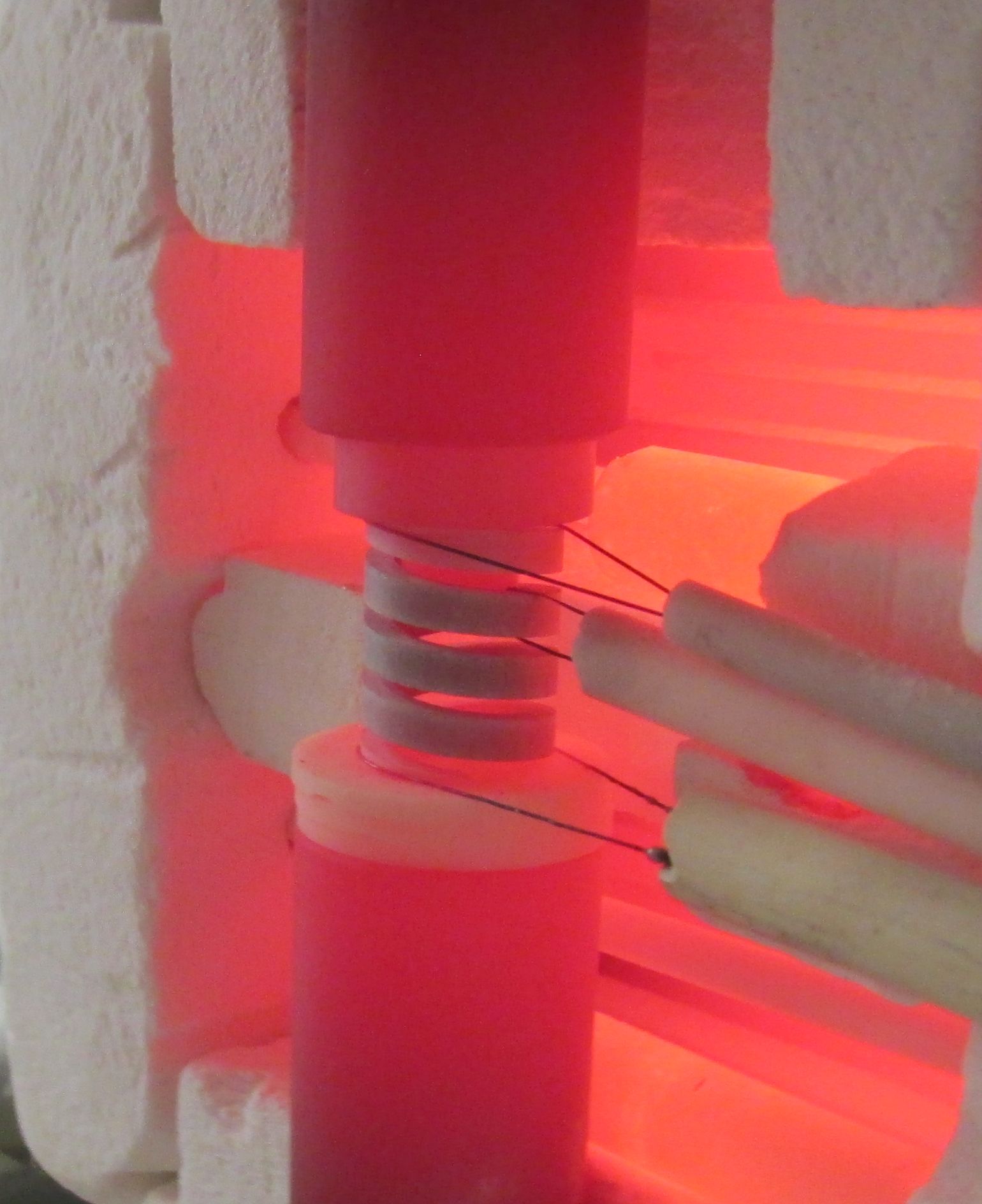

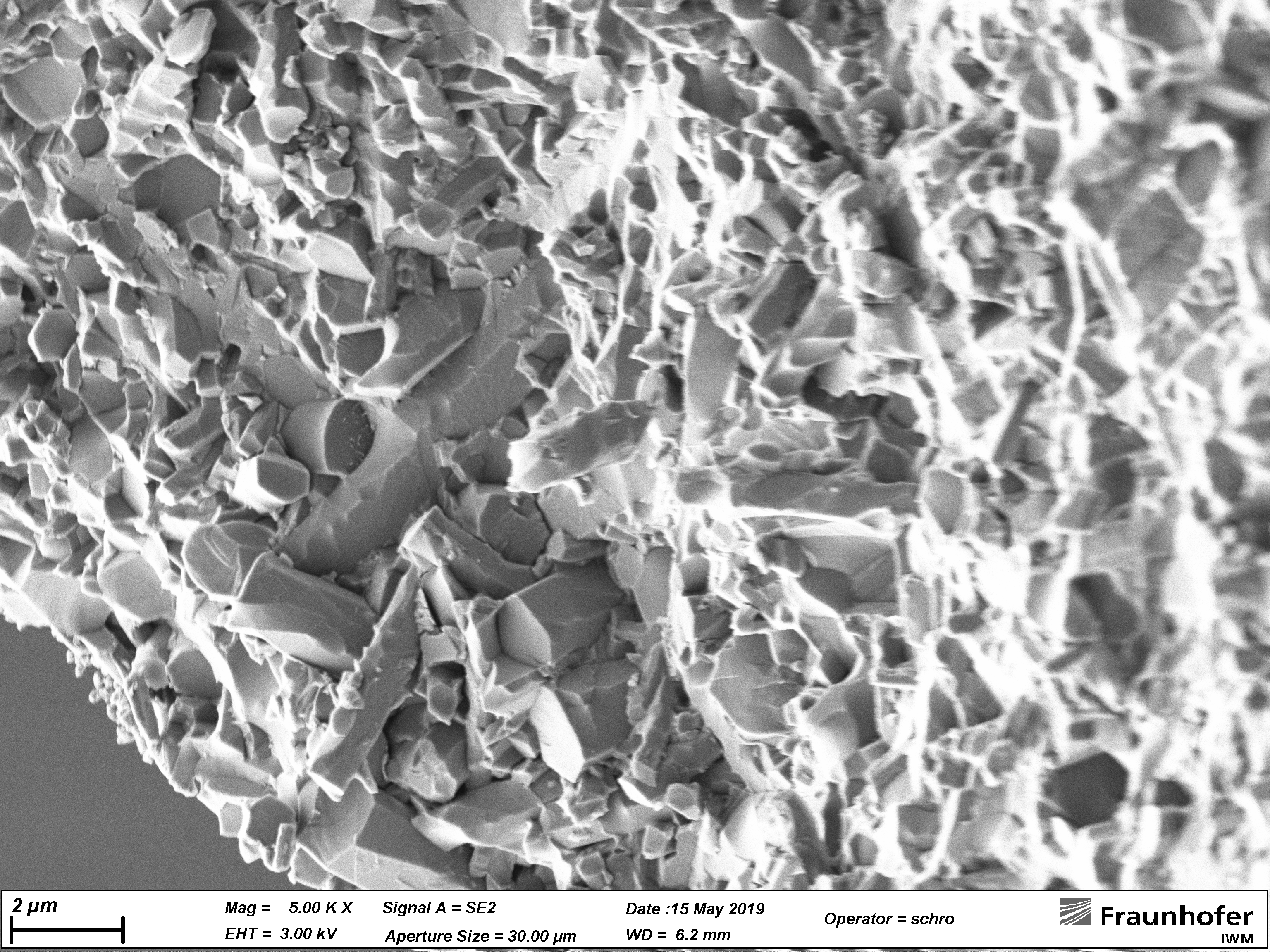

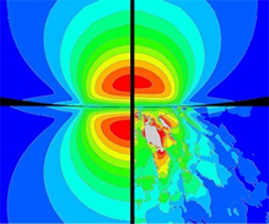

High-performance ceramics are very frequently used as structural ceramics in applications with tribological stresses because they are temperature-resistant, media-resistant and wear-resistant. They also enable very low coefficients of friction - down to superlubricity - and help to improve energy efficiency in tribological systems.

The safe use and exploitation of the advantages of ceramics require not only tribological optimization, but also a design that is as suitable as possible for the material on the basis of the material characteristics.

We help ceramic manufacturers to optimize their materials with regard to specific applications. We test and simulate ceramic materials and components in real-world applications for users of ceramic components

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM