Model Calibration and Process Optimization for Flow and Mixing

Determination of parameters for discrete element models

While some model parameters can be derived directly from the measured values, others must be adjusted using inverse simulation, i.e., the simulation of real experiments. Our experience and a database help us to limit the manual effort involved. By comparing the experiment with the simulation, we then obtain the model parameters best suited to your application.

With our patent-pending FlowBoard, we can record many powder flow properties simultaneously via customized obstructions. This device allows us to calibrate a large number of model parameters with a small number of experiments.

By varying the obstructions used, we can focus on different particle-particle or particle-wall properties such as friction, cohesion, and impact rate. Depending on the obstruction course design, we investigate either the flow behavior of dense flows or the collision behavior of individual particles.

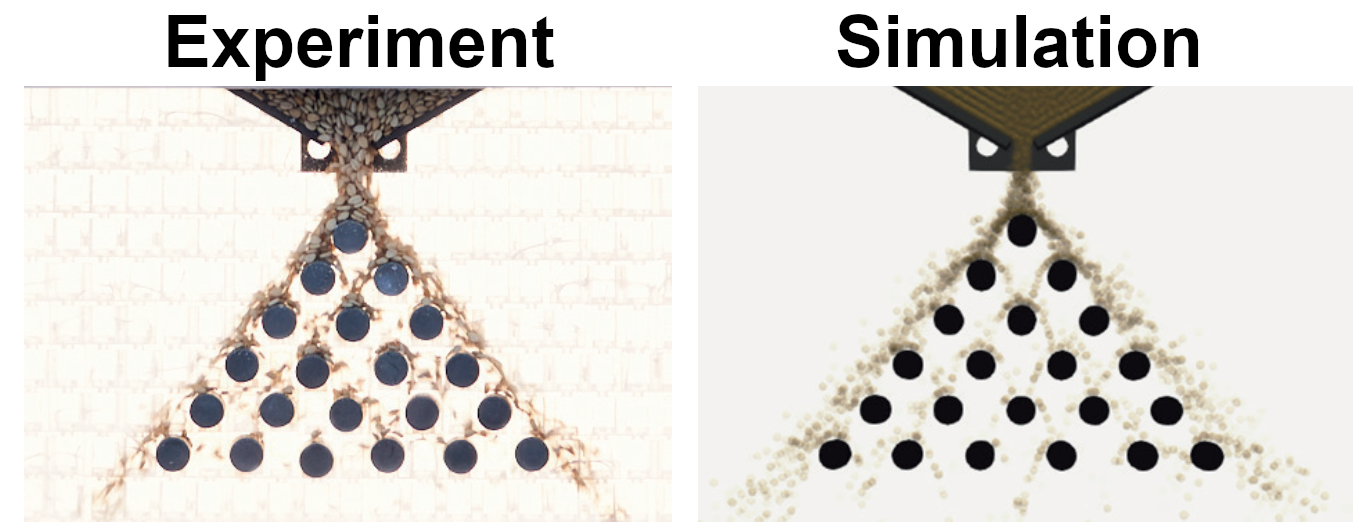

The image on the left compares the flow pattern in the FlowBoard with the corresponding simulation results. This comparison confirms that the flow behavior of the bulk material observed in the numerical simulation corresponds to its behavior in reality.

Simulation of energy-efficient trajectory mixing

The mixing of bulk solids is a fundamental process engineering operation that is used in numerous industries, for example, for powdered active ingredients, fillers, or granulates in the pharmaceutical industry, foods such as flour, sugar, and other dry ingredients, or for metal oxides and graphite or electrolyte powders in battery manufacturing. The requirements for high product quality necessitate thorough mixing of the bulk material, resulting in correspondingly long mixing times. Up to one-third of the total energy requirement of these processes can be attributed to mixing alone.

In collaboration with the company hs-tumbler, a novel mixing concept has been optimized that significantly reduces both the mixing time and the energy requirements of the mixing process. This concept is based on the principle of trajectory mixing (trajectory = curve), in which a container with the bulk material to be mixed follows predefined, mathematically described paths. Abrupt changes in direction and the associated acceleration lead to rapid mixing with low energy input into the bulk material.

The mixing process in the trajectory mixer was numerically simulated and analyzed in detail. These simulations make it possible to determine the degree of mixing over time and provide information about how long different bulk materials need to be mixed and which trajectory delivers the best results. The combination of targeted trajectory control and simulation-based optimization thus opens up a novel, data-based approach to material-specific process design. This makes it possible to determine the optimal mixing setup for each material.

Evaluation of the influence of tool geometry and powder characteristics on filling behavior during die filling

When filling a die for dry compaction, irregularities or incomplete filling may occur due to the insufficient flowability of the powder and the die design. This impairs the quality of the subsequently compacted and sintered components. Simulation using the discrete element method allows such filling processes to be analyzed in advance on the computer. This makes it possible to investigate the influence of the filling speed and the design of the filling shoe on the filling result. In addition to determining the required model parameters, Fraunhofer IWM's expertise also lies in the development of specialized, complex interaction laws between the powder grains, which are adapted to the respective flow behavior.

- Further details on die filling can be found on our SimPARTIX website

- Bierwisch, C.; Kraft, T.; Riedel, H.; Moseler, M., Die filling optimization via three-dimensional discrete element modeling, Powder Technology 196/2 (2009) 169-179 Link

- Bierwisch, C.; Kraft, T.; Riedel, H.; Moseler, M., Three-dimensional discrete element models for the granular statics and dynamics of powders in cavity filling, Journal of the Mechanics and Physics of Solids 57/1 (2009) 10-31 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM