Glass Forming and Machining

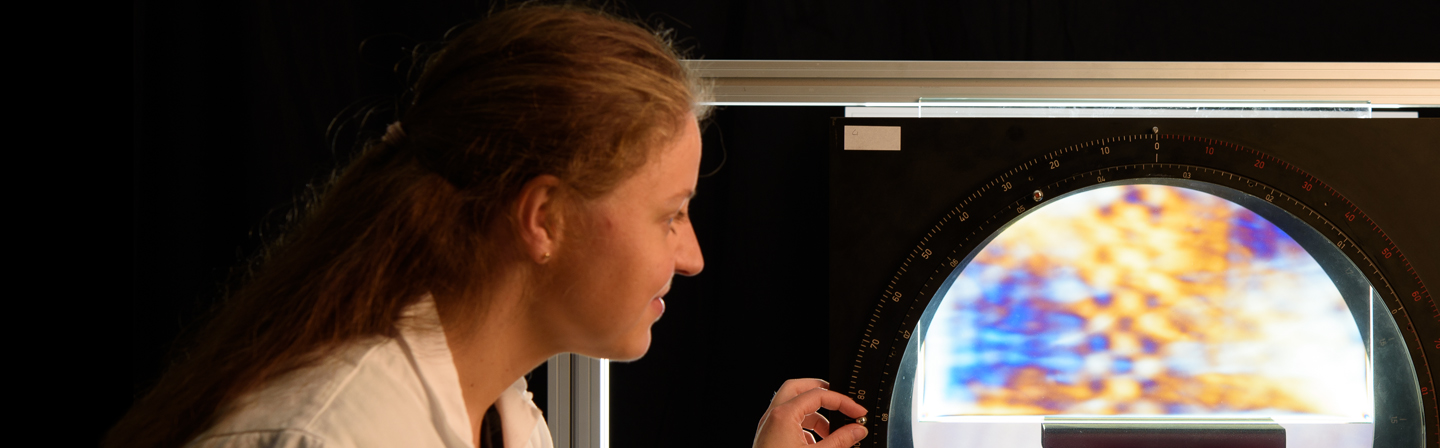

We are specialists in glass, ceramics and semiconductor materials. Our core competencies lie in fracture-mechanical analysis methods and manufacturing processes with a focus on hot glass forming, ultra-precision processing, joining techniques and special separation and cutting techniques. A particular focus is placed on edge-bonding techniques for vacuum-insulating glass, low-damage machining techniques for precise contours in precision components, as well as separation techniques for sheets of laminated glass. Our findings lead to solutions for new processes and products and to the informed assessment of their cost-effectiveness and feasibility in industrial use.

What we offer

- Process development: separating and bending plate glass, hot forming processes, wire cutting for silicon, edge-bonding techniques for vacuum-insulating glass

- Ultra-precision processing of molding tools

- Process analyses for solar cell production to prevent damage and increase yield

- Low-damage silicon separation

- Damage analyses for glass and silicon

- Supporting the process and its assessment through simulations

Contact us! Together we'll find a customized solution for the challenges you face.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM