Accurate simulation of laser powder bed fusion from powder deposition to the microstructure of the component

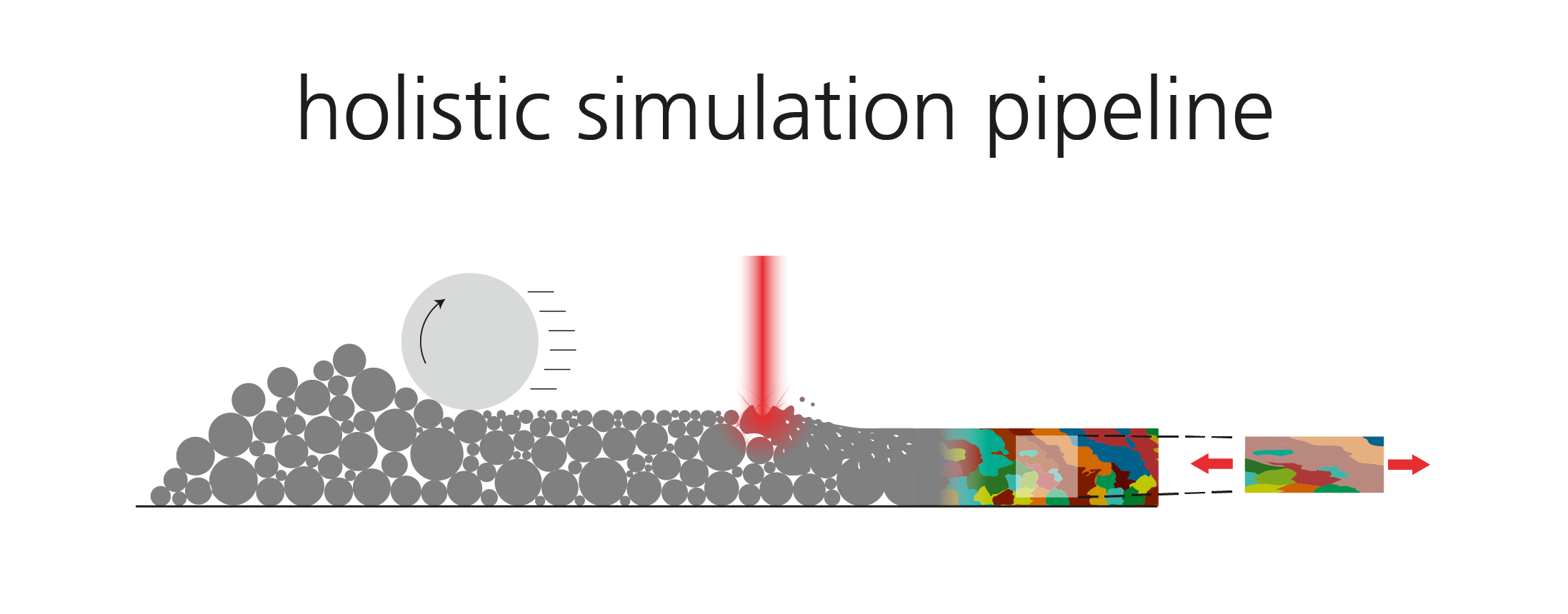

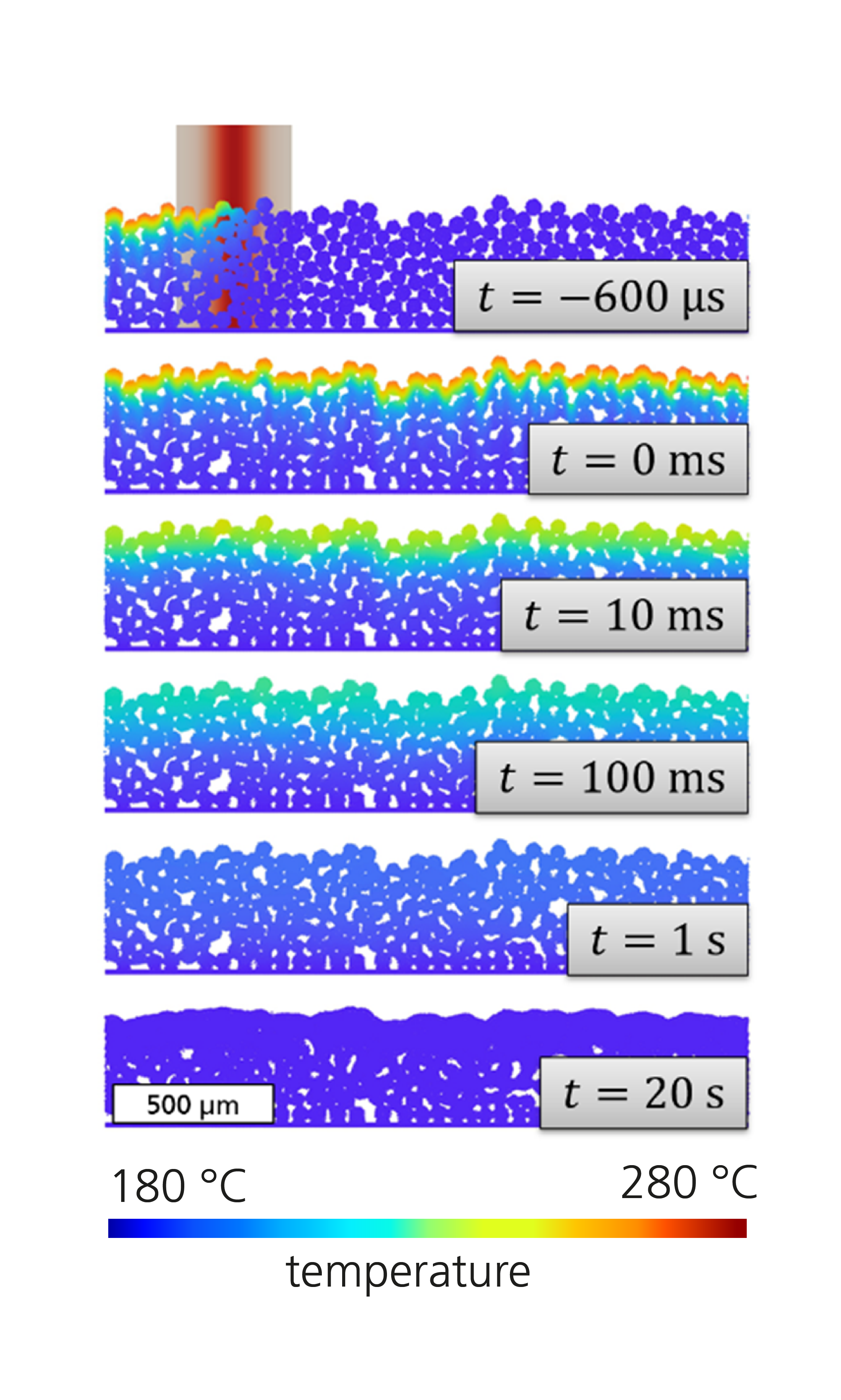

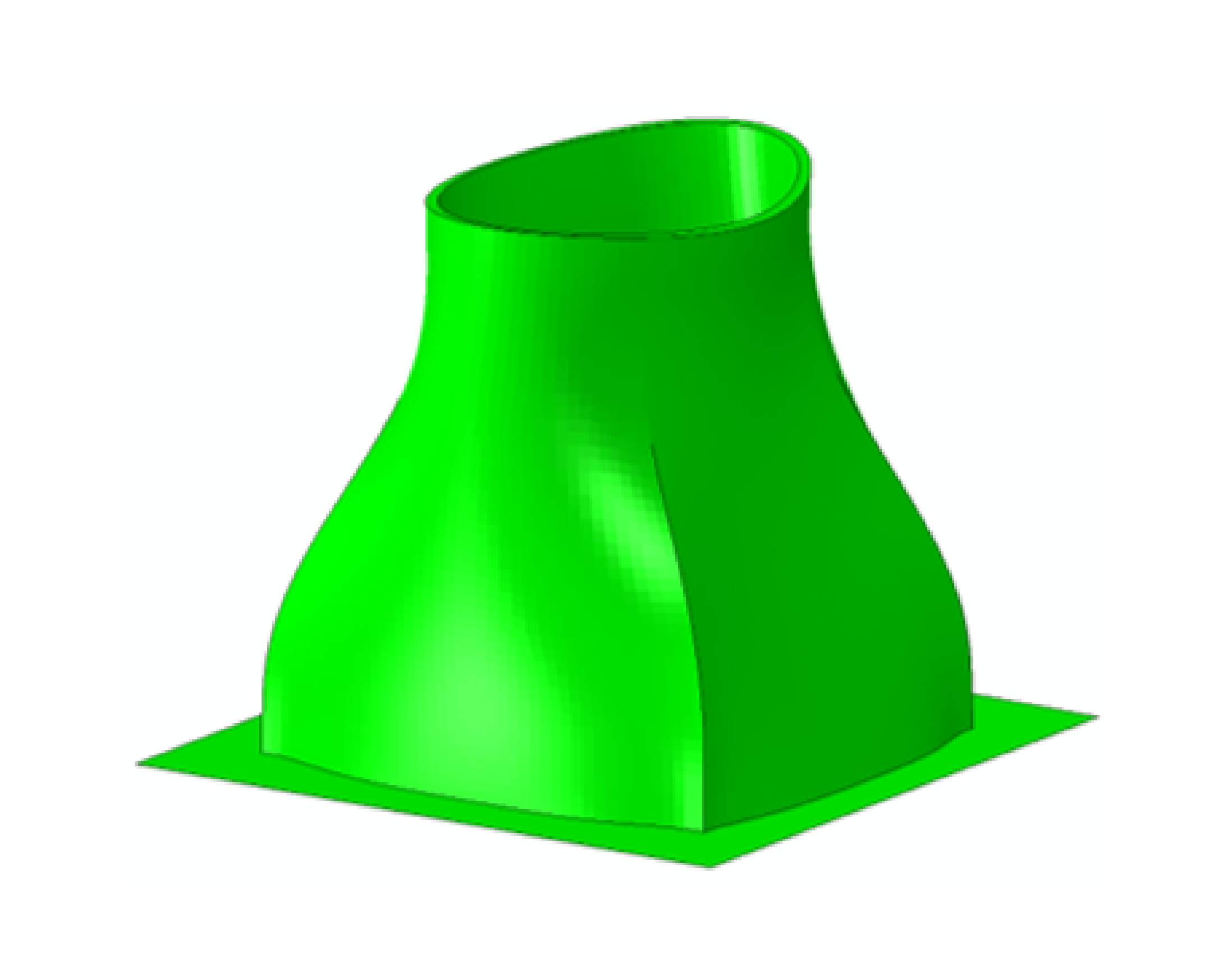

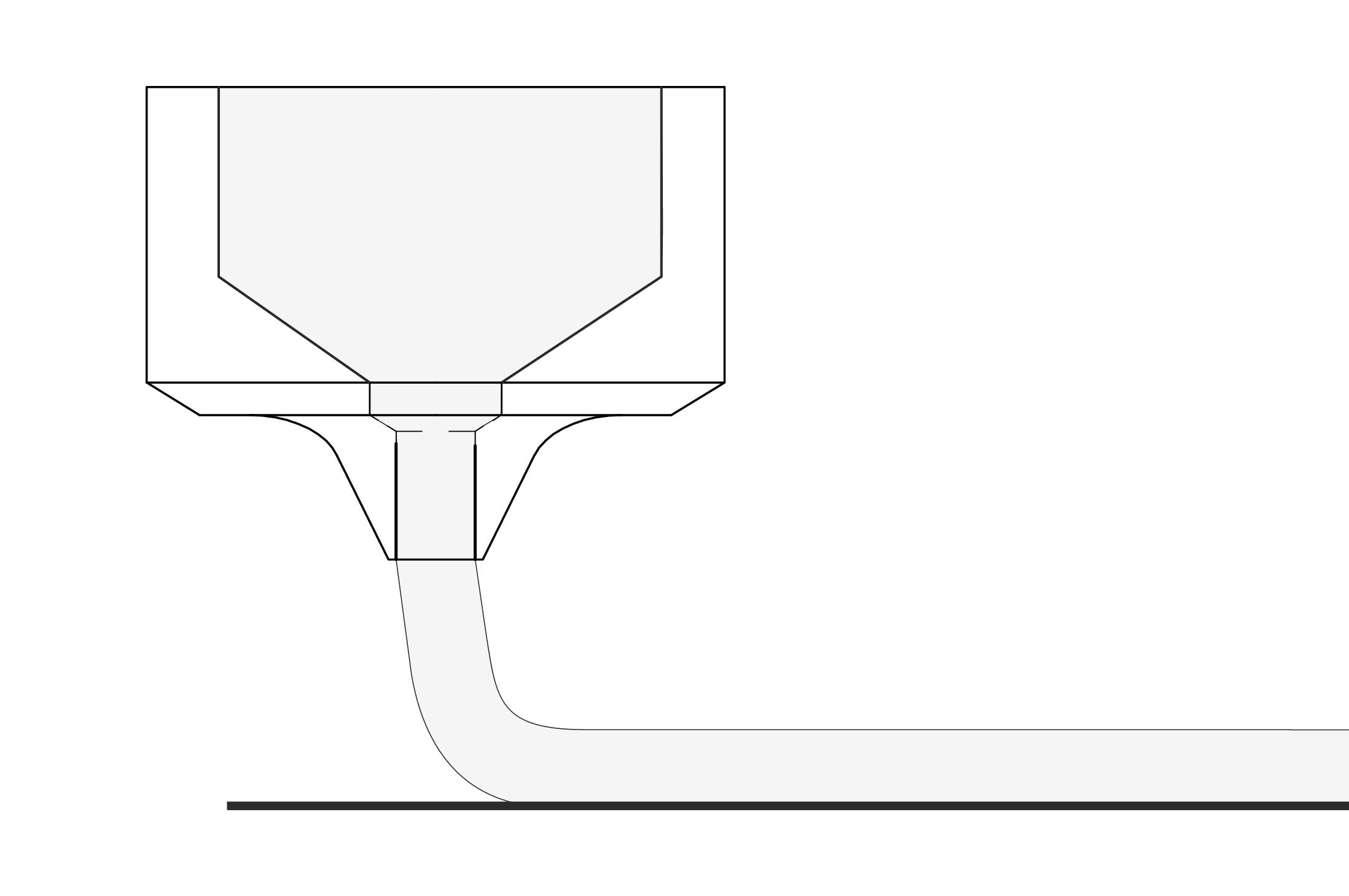

In laser beam powder bed fusion for metals (PBF-LB/M), a subgroup of additive manufacturing processes, the powder applied layer by layer is locally fused. There are numerous optimization options for increasing the printing speed or printing accuracy. Do you want to predict or optimize the material properties and reduce costs in the process? We can help you with this. Fraunhofer IWM enables the simulation of the powder bed process and has developed a simulation chain along the complete PBF-LB/M process, starting with the powder layer application, laser melting and microstructure formation and ending with the estimation of certain local mechanical properties of the manufactured component. The complexity of the process requires the combination of several simulation methods, but also shows which methods are available for process optimization in the powder bed process. The Discrete Element Method (DEM) is used for simulations of the powder application. Ray tracing is used to model the laser beam including possible reflections. Smoothed particle hydrodynamics (SPH) simulations are then used to investigate the flow in the melt pool, taking into account thermocapillary effects and the recoil pressure of the gas phase. The material properties required for this are obtained from thermodynamic CALPHAD simulations. The temperature field of the melt bath is coupled with cellular automaton, which calculates the growth of dendritic grains and thus provides a prediction for the microstructure formed during solidification. This is used to determine the influence of the output of the laser on the microstructure. This microstructure is then used for crystal plasticity finite element analyses for the qualitative description of texture-dependent mechanical properties. The consideration of the complete chain makes it possible to estimate correlations such as the influence of the alloy composition on the workpiece quality. Of course, we can also provide you with a parameter set for your own simulations.

- Bierwisch, C.; Butz, A.; Dietemann, B.; Wessel, A.; Najuch, T.; Mohseni-Mofidi, S.:, PBF-LB/M multiphysics process simulation from powder to mechanical properties, Procedia CIRP 111 (2022) 37-40 Link

- Dietemann, B.; Najuch, T.; Mohseni-Mofidi, S.; Wessel, A.; Butz, A.; Bierwisch, C., Simulation of the laser powder bed fusion process with a holistic workflow, Fraunhofer Direct Digital Manufacturing Conference DDMC 2023; Müller, B. (ed.); Fraunhofer Verlag, Stuttgart (2023) 6 pages Link

- Bierwisch, C.; Dietemann, B.; Najuch, T., Accurate laser powder bed fusion modeling using ISPH, Proceedings of the 17th SPHERIC International Workshop; Fourtakas, G. (Ed.); University of Manchester, Manchester, UK (2023) 255-26 Link

- Bierwisch, C.; Butz, A.; Dietemann, B.; Najuch, T., Multiphysics simulation of laser powder bed melting with mesoscopic models, Foundry 9 (2023) 22-27 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM