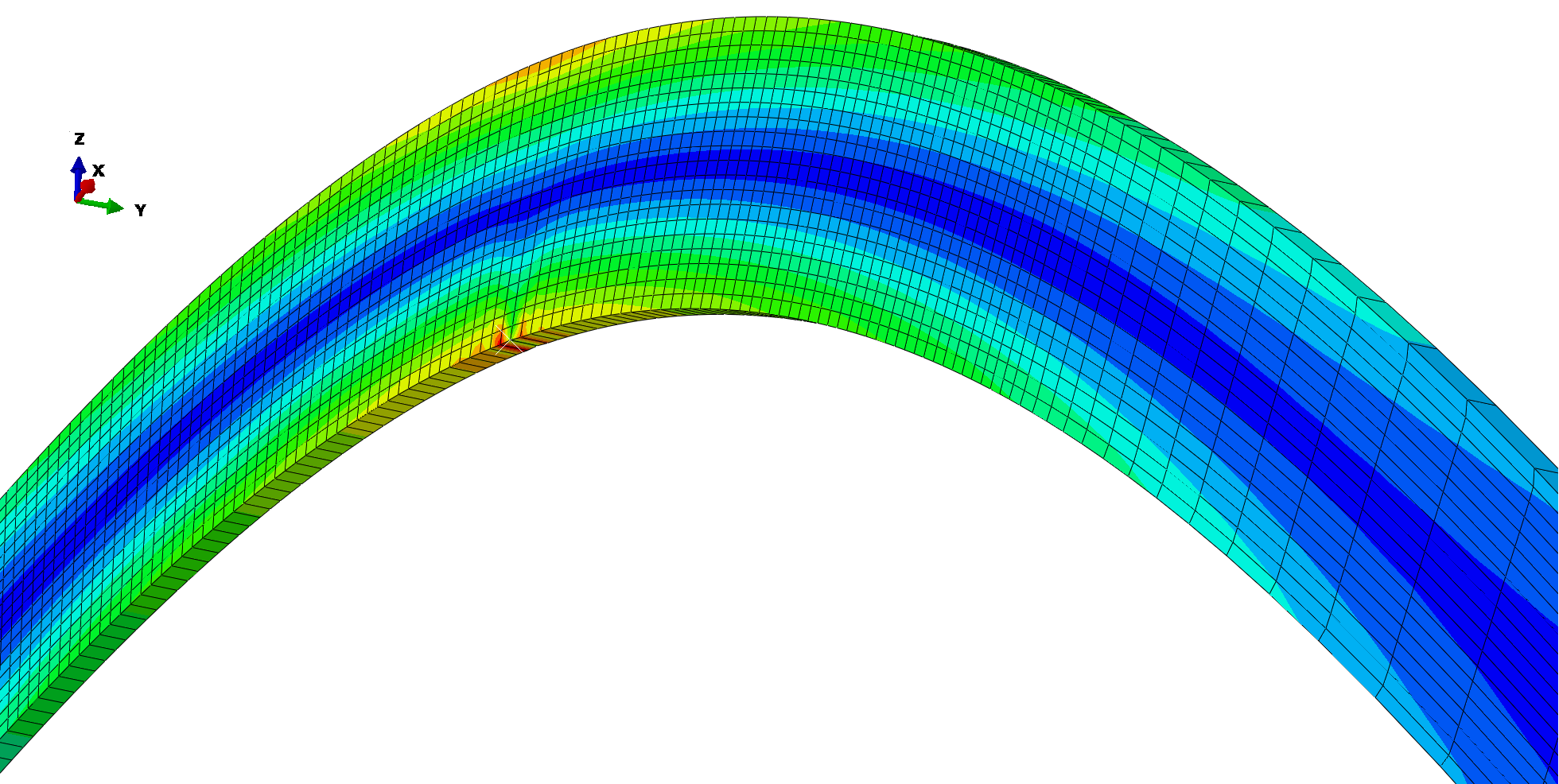

Glass-forming processes are thermal processes and take place at temperatures above 400 °C. During these processes, the impact of forces as well as temperature causes the geometry of the component to change incrementally. The material states change continuously until the final properties are reached in the cold state at the end of the process. A wide range of extensive tests can be carried out on the cold component, but this is not possible while the process is taking place. To access this information, as well as gain deeper insights into the material, we use advanced material models to simulate glass-forming processes, as well as machining processes and loads on glass components such as vacuum-insulating glass.

The following advantages arise for our partners:

- Cost savings by reducing expensive experiments in the design phase

- Fast development and acceleration of process design

- Reliability: Numerical simulations are transparent, and the results are reproducible

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM