If a crack is detected in a cyclic loaded component or its presence cannot be excluded by non-destructive testing, the remaining lifetime of this component can be estimated by the use of the fracture mechanics method. This occurs during the assessment or the dimensioning of railway axles of vehicles in service and newly designed vehicles. Several material and operating aspects have to be taken into account, i.a.:

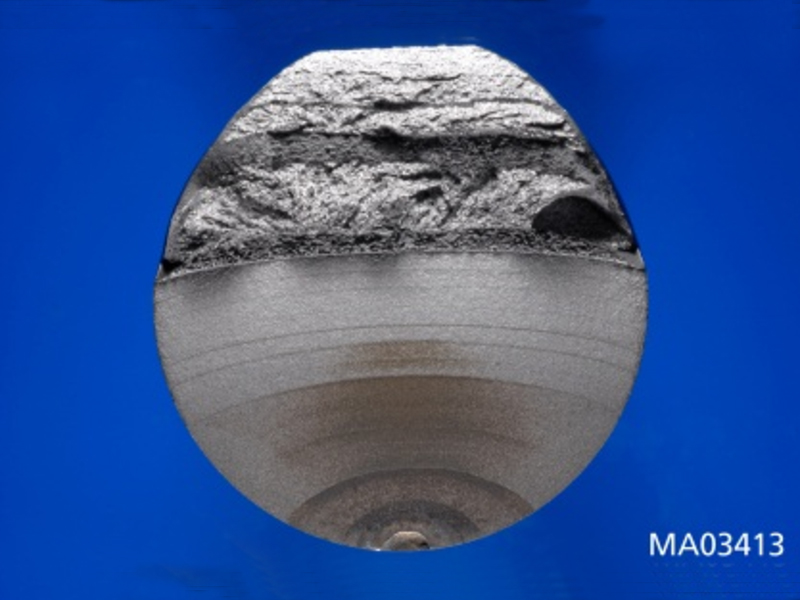

- Representative crack geometry

- Variable amplitude loading

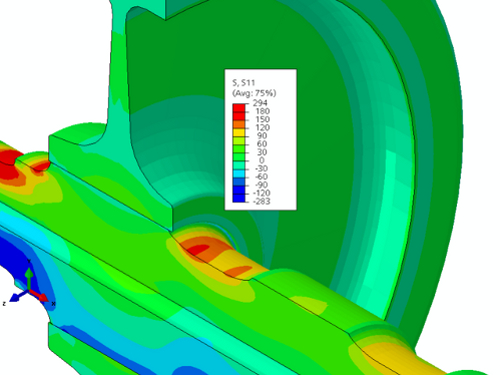

- Stress concentration if the crack is located in a geometric transition region

- Presence of residual stresses due to press fit, mechanical machining, heat treatment

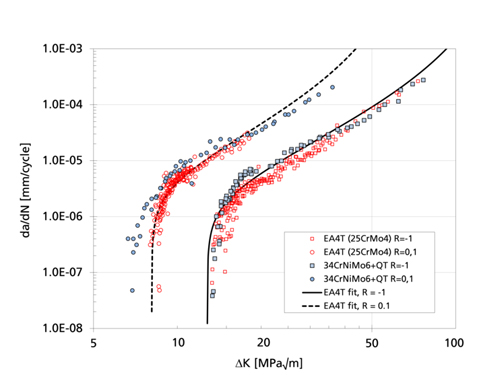

- Comprehensive material characterization because of variable stress intensity ratios

Most of these aspects have been addressed in the research project »Eisenbahnfahrwerke-2« funded by the BMWi and German Railway industry. In addition to the experimental determination of mandatory material parameters, the methodical assessment concept as well as solutions and software for the simulation of the fatigue crack growth in railway axles were developed.

The results of this research project have been successfully implemented in several railway axles dimensioning projects and the derivation of inspection intervals.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM