Meso and Micromechanics

Component improvements often fail because macroscopic material properties are used to design the component. This is because macroscopic material tests record degradation effects and properties that are frequently invalid for critical sections in components. This discrepancy can be attributed, for example, to differences in microstructure, defect statistics or surface-dominated behavior due to miniaturization. Conventional material characterization methods reach their limits because sample geometries are too large or the measurement methods are not sensitive enough.

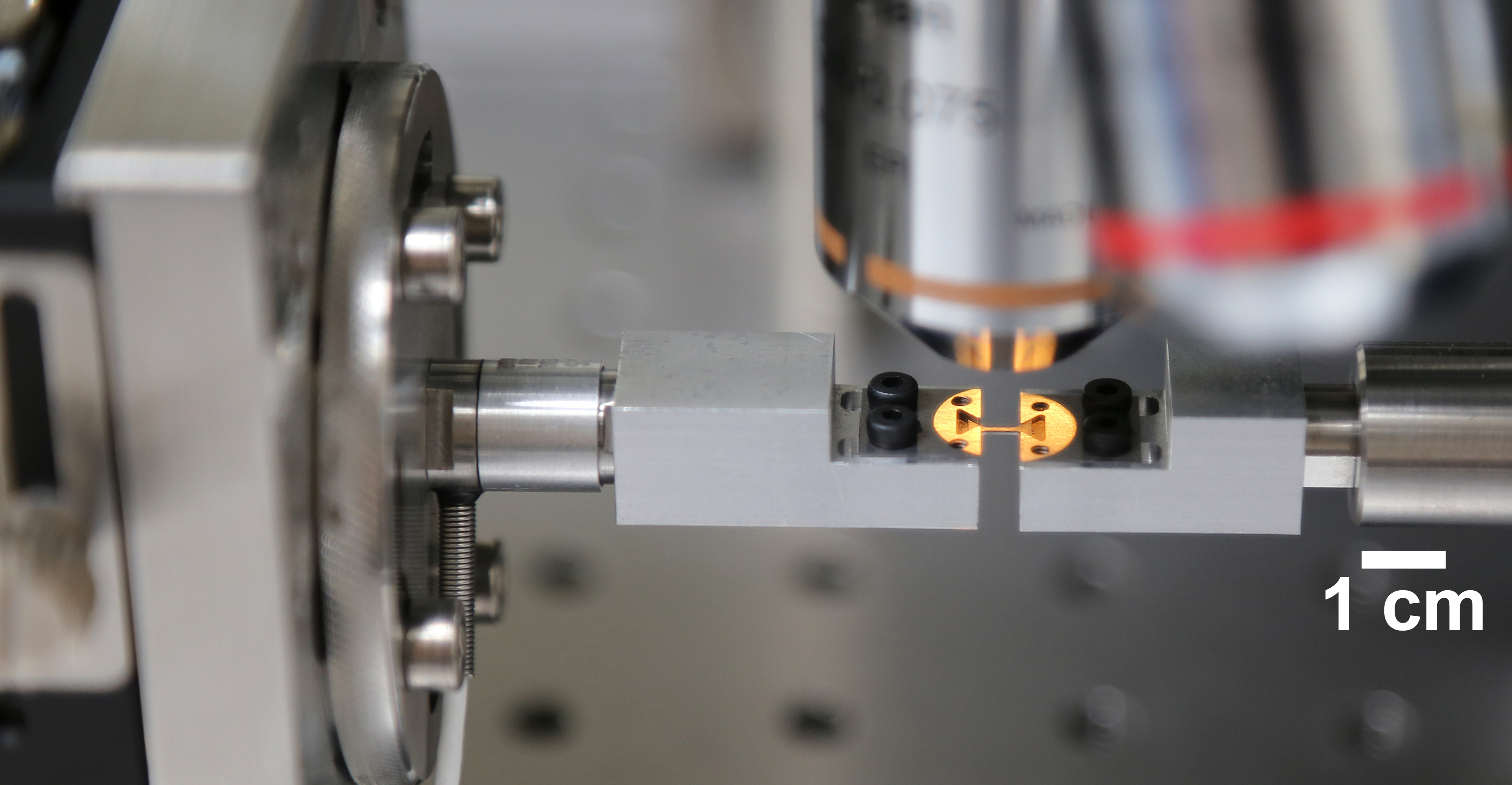

We determine component and material properties of samples with dimensions in the micrometer range, i.e. micro- and mesoscale test specimens. We examine the components holistically in order to derive an understanding of microstructure-property relationships, damage mechanisms and remedial measures. To do this, we use our self-developed test setups from experimental micromechanics, correlative microscopy and intelligent data evaluation methods. Targeted, controlled sample preparation creates the basis for determining realistic component properties of small components and material properties of critical sections in macroscopic components. This enables us to uncover scaling and size effects and improve your material models and component design procedures. As we are continuously developing our modular test setups, we can react very flexibly to special project requirements.

The evaluation of reliability through micromechanical characterization is also a critical aspect for so-called mechanical metamaterials. Based on their internal structure, these artificial materials can for example react to external stimuli (mechanical load, temperature change) by varying their mechanical properties. In this way, new combinations of effective material properties can be achieved that are atypical for conventional materials. Using such metamaterials, components can be "programmed" and tailored for your applications. One focus of our group is concerned with the design and characterization of such metamaterials, as relevant dimensions of the internal structure are usually on the mesoscale.

R&D services for Meso and Micromechanics

Mechanical testing of microsamples

With our micromechanical test setups, we characterize samples in the micrometer range, examine the smallest components and determine the local properties of macroscopic structures. This enables us to evaluate mechanical scale and scaling effects, which cause additional scatter in the mechanical properties during miniaturization. We carry out quasistatic and cyclic tensile and bending tests, controlled by force or displacement. We also offer strain-controlled fatigue tensile tests.

Detecting fatigue damage before cracks form

With our multiaxial resonance fatigue apparatus, we detect early signs of fatigue such as pore, slip band, extrusion and crack initiation in individual grains as well as the growth of micro and short cracks via a characteristic drop in the resonance frequency of microsamples.

Development of programmable material behavior on the meso and microscale

Increasingly complex material behavior requirements are pushing the classic concepts of material selection and design to their limits. In the Fraunhofer Cluster of Excellence Programmable Materials CPM, together with other Fraunhofer institutes, we are researching so-called "Programmable materials" that adapt to environmental conditions, replace classic system approaches or can be applied to other properties.

AI concepts for materials development and materials technology

Our group develops, qualifies and optimizes novel data-driven approaches for materials science and materials technology issues. We support you throughout the entire process chain, from suitable data collection, optimal data preparation and model selection through to training, evaluation and deployment.

Why should my company collaborate with the Fraunhofer IWM on meso and microscale material and component testing?

Our experiments detect initial fatigue damage with very high sensitivity.

The attenuation and therefore the signal-to-noise ratio are significantly reduced due to the miniaturization of the samples. Processes such as the formation of slip bands, extrusions or crack initiation can therefore be measured. This allows conclusions to be drawn about fatigue mechanisms.

We carry out time-lapse fatigue tests.

9Due to reduced damping and the advantageous scaling of the resonance frequency during miniaturization, fatigue properties can be determined within a few days, even with load cycles of up to 10. Frequency effects are taken into account during fatigue.

We generate defined loading conditions and a fully-fledged time-resolved representation of the sample state.

Analytical methods for determining the microstructure or local surface roughness can be recorded for the entire sample within portable measurement times. These fully-fledged data collections can be used to extract dependencies that might otherwise remain undetected. This can be achieved, for example, through data mining using machine learning methodologies.

We port fully-fledged representations of sample volumes into simulation methods such as CPFEM or discrete dislocation dynamics.

These computationally intensive methods can handle similar sample volumes. By linking and synergizing simulation and experiment on the same scale, insights into fatigue driving forces can be derived. In addition, micromechanical data can be used to calibrate and validate these methods.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM