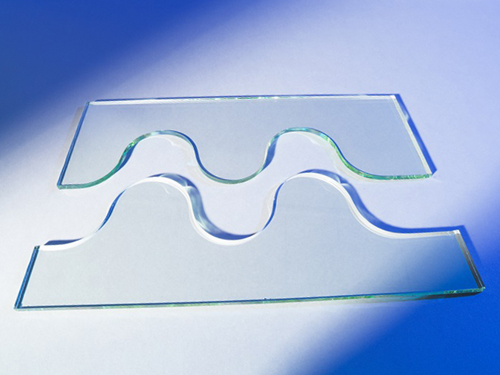

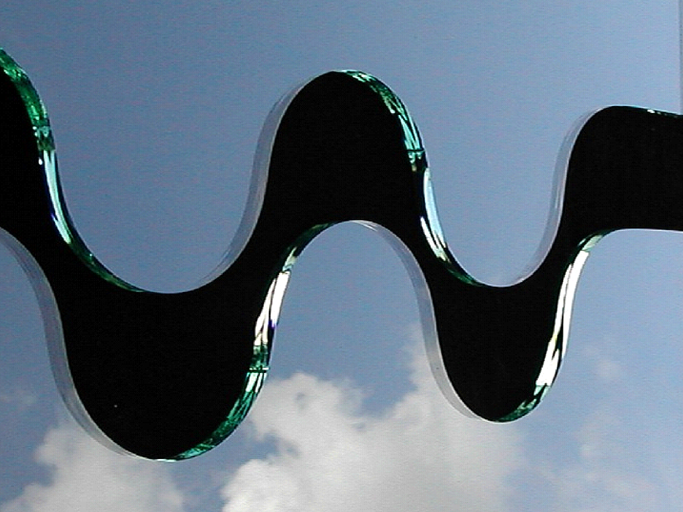

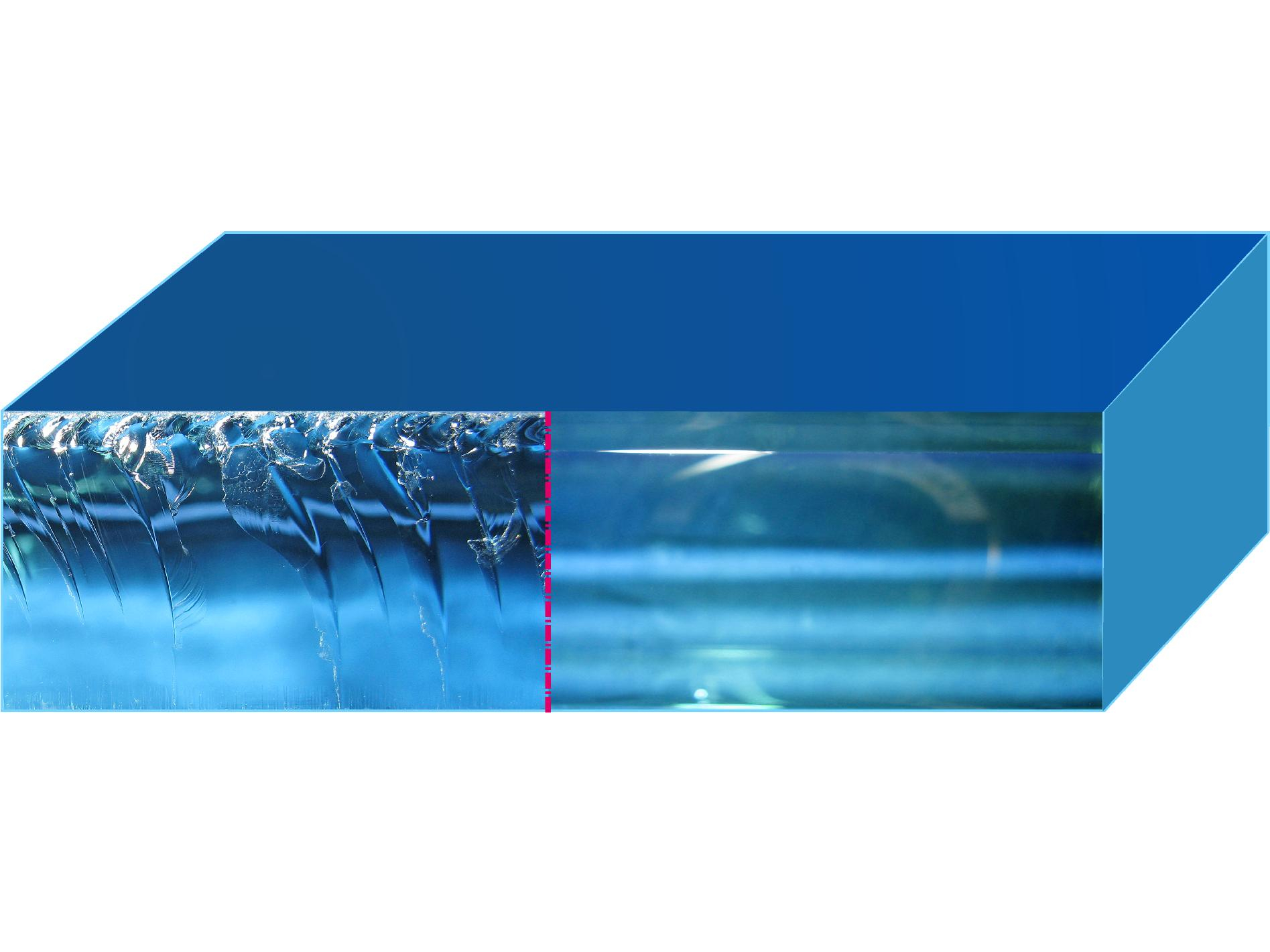

Conventional cutting processes, such as scribing and breaking glass, create microcracks in the fractured edge. In contrast, the thermal cutting process developed at Fraunhofer IWM enables a fractured edge with fewer and smaller defects. The use of a laser facilitates the introduction of heat into the glass with temporal and spatial precision. In this way, the separation crack is guided through the glass with contour precision by local stresses.

Cutting Glass

Left image: Conventional separation (mechanical scribing and bending fracture). Right image: Laser-induced tension separation (thermal scribing and bending fracture).

- Glass separation

- Separation of laminated safety glass by means of independent separation processes for the foil inside the composite

- Cutting free forms from laminated safety glass

- Separation of laminated safety glass, in which first the film and then the glass are separated automatedly with precise contours

- Process provides new possibilities in the realization of customer-specific contours and the path to automated cutting of laminated safety glass models

- Various laser sources and wavelengths

- Mechanical testing methods (tensile test, bending, double ring)

- Microscopic analysis methods (light microscopy, scanning electron microscope)

- Simulation (finite elements, particle-based numerical methods)

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM