Determination of characteristic values for forming simulations using the »Virtual Lab«

The »Virtual Lab«

The crystalline structure of metals in forming processes can have a significant influence on the mechanical behavior: for example, the development of grain orientations, in other words, crystallographic texture and grain morphology influence the plastic deformation behavior of the material. Using the »Virtual Lab«, we simulate such microstructural changes and analyze the resulting effects on the material behavior across different length scales. This enables us to predict the development of material properties such as texture and flow behavior.

How the »Virtual Lab« works

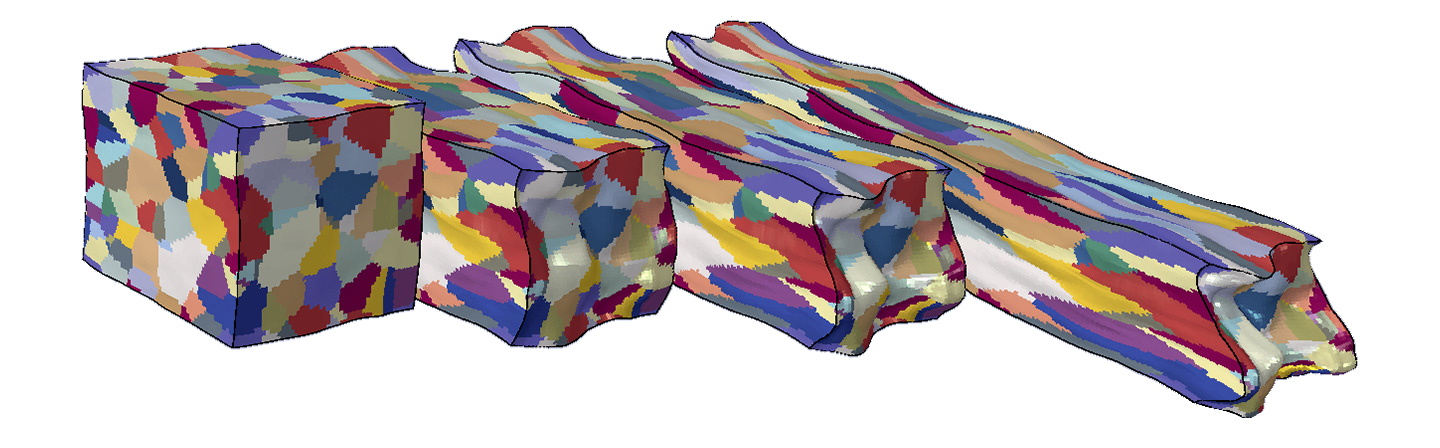

A digital twin of the material to be studied is created inside the »Virtual Lab«. The constitutive model used considers the material’s microstructure in the form of a representative volume element, see Figure 1. The individual grains of the microstructure are spatially resolved, whereby parameters such as grain shape, grain orientation and phase distribution are taken into account. Due to the consideration of the grain’s orientation, the anisotropic material behavior is also included within the digital twin. For the calibration of the microstructural model only a few experiments are required: typically, one tensile test in rolling direction is used for sheet metal materials. By modifying the boundary conditions the digital twin can be easily used to perform further »Virtual Experiments« and therefore different loading cases can be studied.

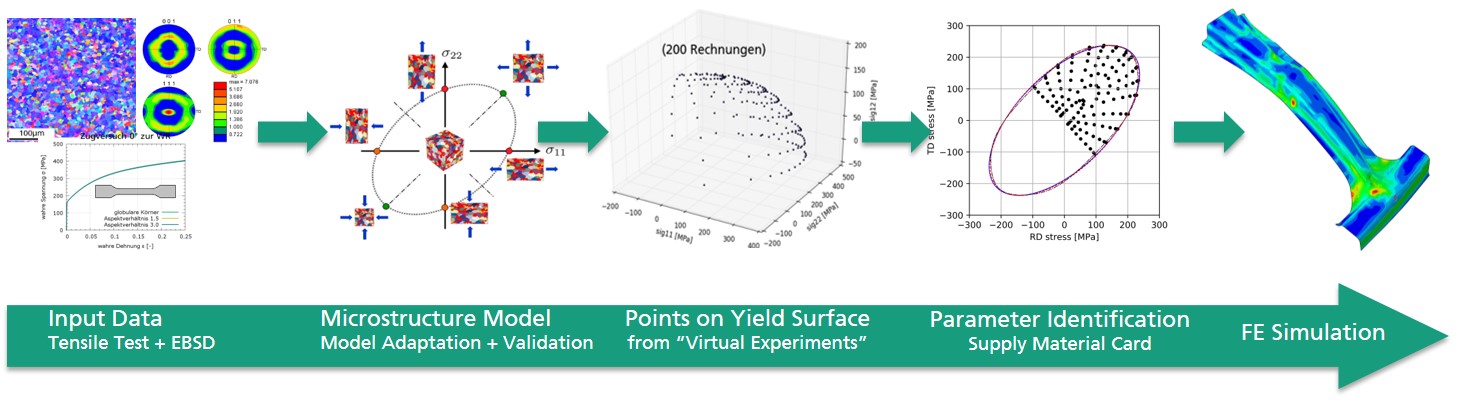

Virtual determination of characteristic values for sheet metal forming simulation

The »Virtual Lab« is an efficient simulation tool for analyzing macroscopic material properties of sheet metal materials and extends the conventional, experimental testing procedure typically applied, see Figure 2. In particular, complex material models, which are more and more required for modern, high-strength sheet metal materials, benefit from the additional data obtained by the »Virtual Lab«. Considering sheet metal forming applications in general, the »Virtual Lab« can be applied in various ways:

- Determination of Young’s moduli, initial yield strengths and r-values in different angles with respect to the rolling direction

- Identification of any number of points on the initial yield surface to identify parameters of anisotropic yield models

- Implementation of complex and multi-axial loading conditions, replacing very elaborate experiments

- Analysis of loading conditions, which cannot be realized via experimentation; for example tensile tests in thickness direction of a sheet

- Characterization of difficult manageable materials, e.g. ultra-thin metal foils

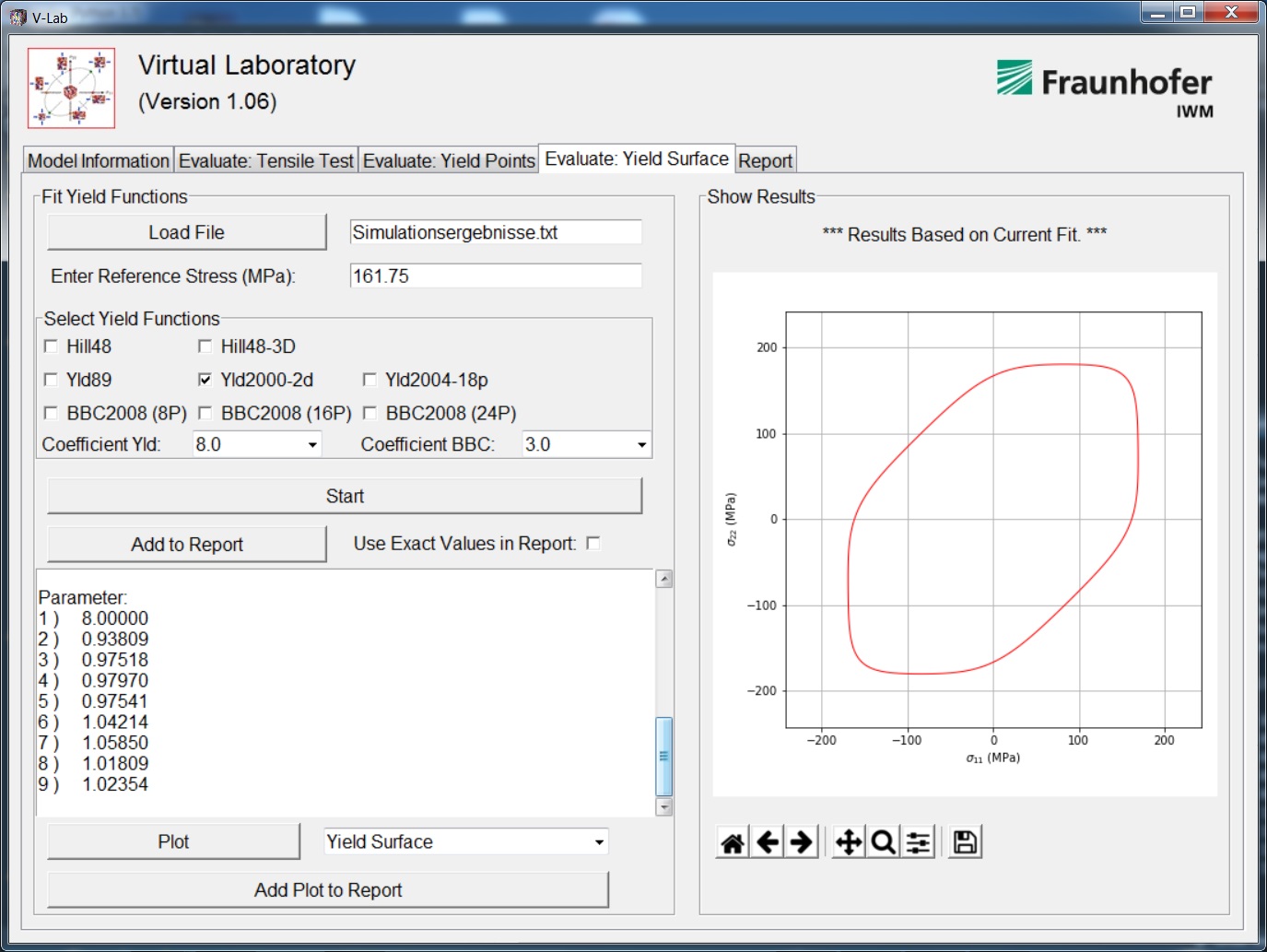

Efficient post-processing using the »Virtual Lab« app

Data resulting from the »Virtual Lab« can be further processed in the same way as experimental data. In order to make this process as simple as possible, an app is available to our customers in which the evaluation of »Virtual Experiments« and the creation of material cards for FE simulation can be efficiently carried out, see Figure 3. In addition, it is possible to store further details within the app, such as experimental measurement data and model information. Furthermore, automatically generated reports can be created, which include all essential information on the microstructure simulations, the evaluation of simulations and the material parameters identified.

Our services

- Setup of microstructure models based on EBSD measurements

- Calibration and validation of model parameters by means of standard test data

- Implementation and evaluation of microstructure simulations considering various loading conditions

- Determination of macroscopic values such as flow curves, parameters for anisotropic yield models and r-values

- Supply of microstructural simulation data out of the »Virtual Lab«, which can be further processed by the costumer using the »Virtual Lab« app

In addition, we are happy to support you with the know-how available at the Fraunhofer IWM so as to assist in building up your own competencies for carrying out »Virtual Experiments«.

Publications

- Wessel, A.; Perdahcioglu, E. S.; van den Boogaard, A. H.; Butz, A.; Volk, W., Incorporating precipitation-related effects on plastic anisotropy of age-hardenable aluminium alloys into crystal plasticity constitutive models, Materials Science and Engineering: A 924 (2025) Art. 147714, 17 pp. Link

- Wessel, A.; Morand, L.; Helm, D.; Volk, W., Machine learning-based sampling of virtual experiments within the full stress state, International Journal of Mechanical Sciences 275 (2024) Art. 109307, 19 pp. Link

- Wessel, A.; Perdahcioğlu, E. S.; Butz, A.; van Den Boogard, T.; Volk, W.; Prediction of texture-induced plastic anisotropy in AA6014-T4 aluminium sheets utilising two different crystal plasticity-based constitutive models, IOP Conference Series: Materials Science and Engineering Vol. 1284, 42nd Conference of the International Deep Drawing Research Group IDDRG 2023, IOP Publishing Ltd, Bristol, UK (2023) Art. 012059, 10 pp. Link

- Wessel, A.; Schilling, M.; Willmann, T.; Butz, A.; Bischoff, M., Higher-order 3D-shell elements and anisotropic 3D yield functions for improved sheet metal forming simulations: Part II, in Proc. of 14th European LS-DYNA Conference 2023; DYNAmore GmbH, Stuttgart (2023) 10 pp. Link

- Wessel, A.; Morand, L.; Butz, A.; Helm, D.; Volk, W., A new machine learning based method for sampling virtual experiments and its effect on the parameter identification for anisotropic yield models, IOP Conference Series: Materials Science and Engineering Vol. 1157, 40th International Deep-Drawing Research Group Conference IDDRG 2021; Liewald, M.; Karadogan, C. (Eds.); IOP Publishing Ltd, Bristol, UK (2021) Art. 012026, 9 pp. Link

- Willmann, T.; Wessel, A.; Beier, T.; Butz, A.; Bischoff, M.; Cross-sectional warping in sheet metal forming simulations, in Proc. of 13th European LS-DYNA Conference 2021; DYNAmore GmbH , Stuttgart (2021) Art. 087, 8 pp. Link

- Wessel, A.; Butz, A.; Willmann, T.; Bischoff, M., Effect of different anisotropic 3D yield functions on a roller hemming simulation, Procedia Manufacturing 47 (2020) 1358-1365 Link

- Butz, A.; Wessel, A.; Pagenkopf, J.; Helm, D.: Parameter identification of 3D yield functions based on a virtual material testing procedure. IOP Conference Series: Materials Science and Engineering 651(2019) Art. 012078, 8 pp. Link

- Butz, A.; Pagenkopf, J.; Baiker, M.; Helm, D.: The concept of virtual material testing and its application to sheet metal forming simulations. Journal of Physics: Conference Series (2016): 1-4 Link

- Pagenkopf, J.; Butz, A.; Wenk, M.; Helm, D.: Virtual testing of dual-phase steels: Effect of martensite morphology on plastic flow behavior. Material Science & Engineering: A 674 (2016): 672-686 Link

- Baiker, M.; Helm, D.; Butz, A.: Determination of mechanical properties of polycrystals by using crystal plasticity and numerical homogenization schemes. steel research international 85.6 (2014): 988-998 Link

- Helm, D.; Butz, A.; Gumbsch, P.; Raabe, D.: Microstructure-based Description of the Deformation of Metals: Theory and Application. JOM Journal of the Minerals, Metals and Materials Society 63 (2011): 26-33 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM