The joint research project "GearOil-LOOP", which comprises three research institutes and six industrial partners, aims to create an economical and innovative circular economy for high-quality lubricants. In the project, the consortium aims to develop a recycling process as well as a gear oil that is especially suitable for circularity and contains at least 50 percent recycled base oil. This prototype will be used to demonstrate how an industrially and economically feasible recycling process works.

This goal is challenging, not least because a recyclable gear oil and the recycling process are being developed and tested at the same time. This dual development strand requires intensive cooperation between all partners along the development and value chain. In addition to lubricant development and lubricant recycling, important stages include testing options for the application behavior of the lubricants in gearboxes and bearings as well as fundamental investigations into friction and wear behavior, which are intended to confirm that the developed lubricants can keep up with conventional, i.e. non-recycled gear oils in terms of their performance and durability. The sustainability of the closed-loop concept will also be evaluated, taking into account the raw materials, manufacturing and recycling processes and the performance of the lubricants.

With this development project, the consortium aims to create a circular economy for gear oils in which the fossil raw materials involved can be used for as long as possible and as little waste and CO2emissions as possible are generated. "GearOil-LOOP" opens up a new field of circular economy with recyclable, higher-viscosity gear oils and the necessary recycling technologies.

Project results

Recyclable, high-viscosity gear oil

The current recycling processes for high-quality gear oils are inadequate and most processes are limited to low-viscosity oils. The "GearOil-LOOP" project is developing a high-viscosity gear oil that is especially suitable for recycling, consists of more than 50% recycled base oil and meets current standards. In addition to improving existing formulations, innovative additives are also used.

Differentiated circulation system for high-viscosity gear oils

The project is designing an innovative recycling system that is specially tailored to the requirements of high-viscosity gear oils. The aim is to achieve energy-efficient recycling processes that enable high-quality recovery of base oils. The optimized procedures increase the efficiency of the entire recycling process and improve the quality of the recycled lubricants, resulting in lower production costs and reduced CO2 emissions for the industry.

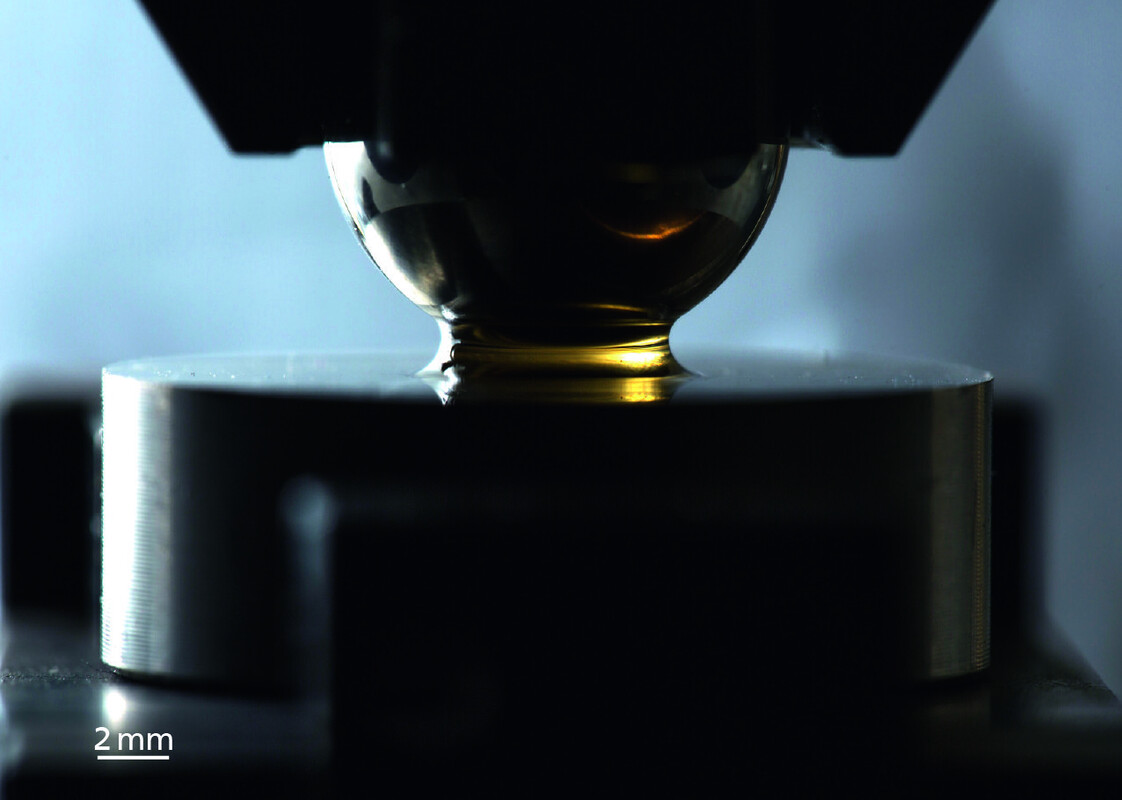

Comprehensive tribological assessments and proof of performance

A central component of the project is the tribological evaluation of the recycled oils under realistic operating conditions. The performance of the new lubricants in comparison to conventional oils is checked by means of extensive tests on transmission components. This quality assurance promotes the acceptance and use of recycled oils, optimizes the life cycle of the products and reduces maintenance and operating costs.

Sustainability assessment and market integration

As part of "GearOil-LOOP", a comprehensive sustainability assessment is carried out that quantifies the savings in greenhouse gas emissions and resources. These assessments support an economically viable concept for the recycling of gear oils. The benefit for the industry is not only the fulfillment of regulatory requirements, but also the strengthening of brand reputation through environmentally friendly product solutions.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM