Technical ceramics are generally used where other construction materials such as metals and plastics reach their limits under severe application conditions, especially under mechanically demanding applications at high temperatures and/or when withstanding chemically aggressive situations.

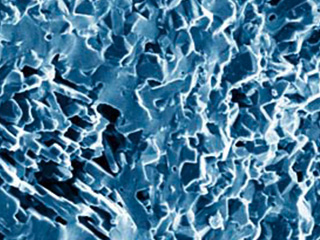

Although ceramic materials are harder, stronger and more corrosion and wear resistant than polymers and metals, they may also cause problems due to their low damage tolerance. This can even lead to complete failure of ceramic components. A comprehensive analysis of the causes may then help both in preventing future failures as well as in minimizing the risk of failure in the first place by choosing appropriate materials and through component testing.

As with all material groups, the causes of failure are varied and can be mostly attributed to overlapping load conditions. However, these causes within the varied material groups need to be properly assessed. Evaluating ceramic components and the causes for their failure requires a particular focus upon material quality (microstructure, surface finish). Moreover, long-term damage caused by cyclic loading or corrosive attack needs to be analyzed.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM