Part of our everyday experience is that technical systems, devices and equipment become damaged. This frequently results in time lost, repair costs, the need for new plans or redesigns and very often follow up costs for consequential damages and recourse claims.

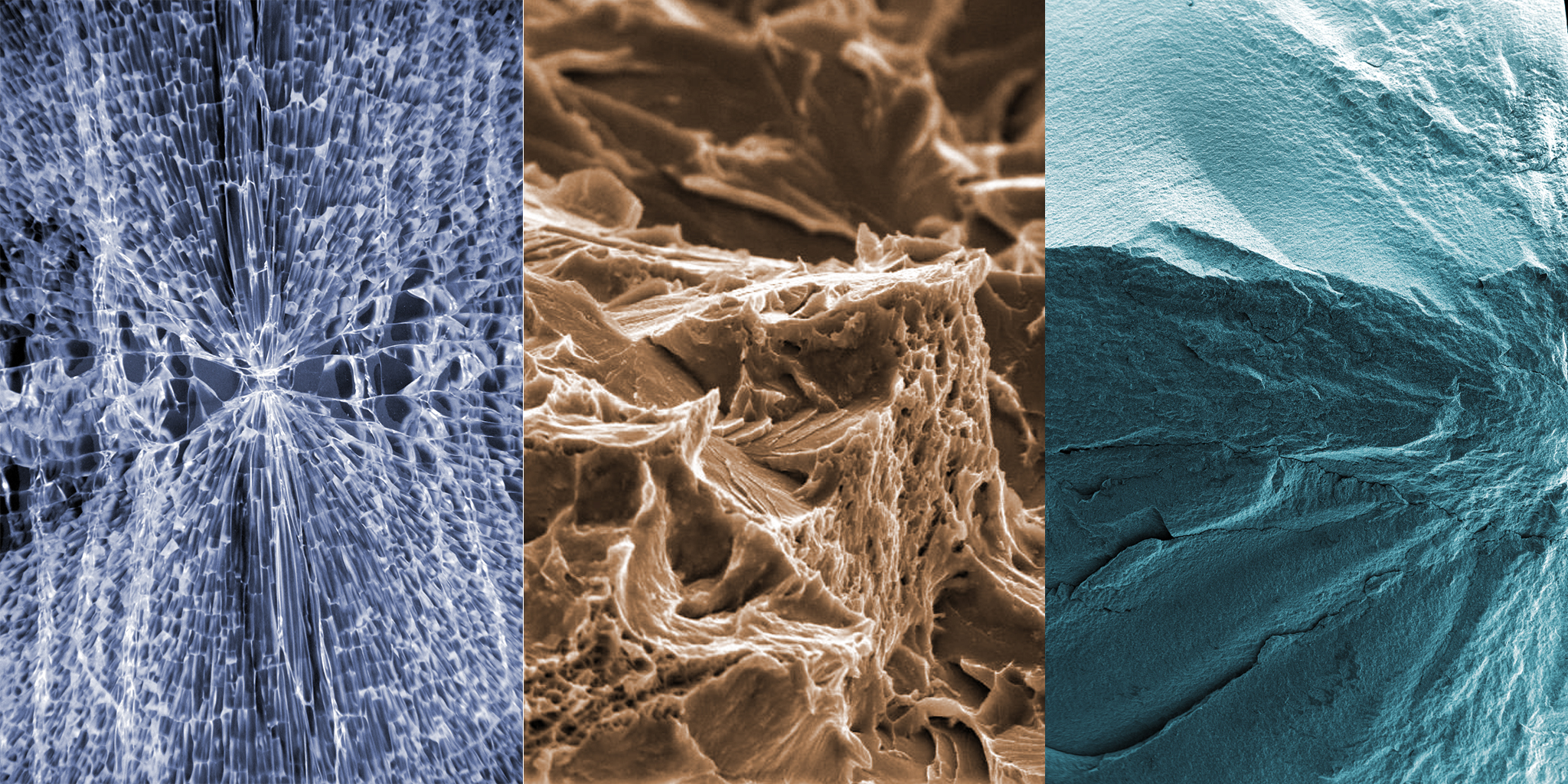

At the Fraunhofer IWM we analyze the causes of the damage and clarify damage mechanisms. It only occurs in very rare cases that a single, isolated event causes damage. Generally, it is necessary to consider several factors, such as component geometry, the microstructure of a material as well as its load (mechanical, thermal, chemical and tribological) and to understand the complex interactions between all of these. Based on our practical work, extensive analytic capabilities, the most modern computing and simulation techniques and – last but not least – our many years’ experience in the field of application related use of materials, we understand the correct prioritizations to properly clarify the causes of damage. This applies especially to tools and components made of metal, ceramic and glass as well as for material compounds.

We would be glad to support you by clarifying the causes of damage as well as by introducing and implementing practical measures for avoiding damage. Simply reach out to the contact partner listed on the appropriate damage analysis page – we’ll put together the right team to address your damage related issues.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM