Influence of the tool geometry and powder characteristics on the die filling process

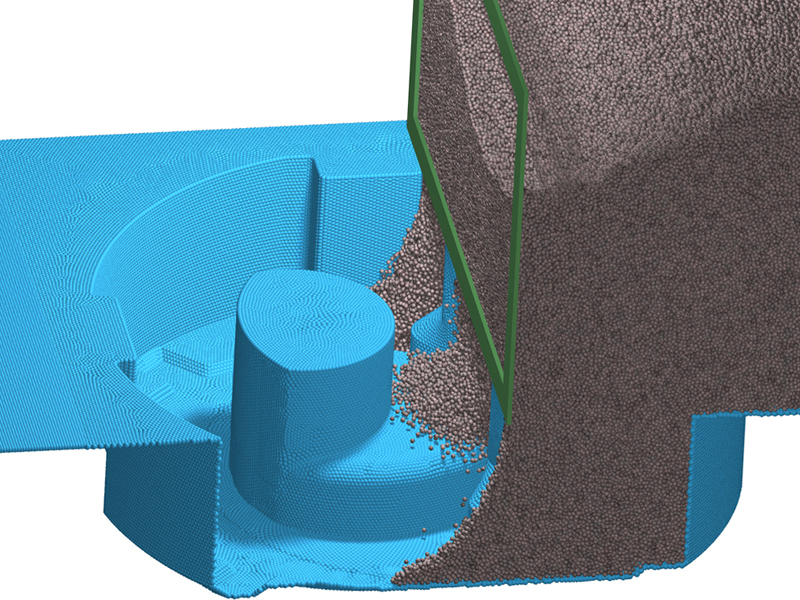

When die filling - the first step in the classical powder technological process chain – both the flow behavior of the powder or the design of the die, as well as that of the filling shoe, can result in inhomogeneous or incompletely filled cavities. This operation can be thoroughly examined in advance via computer simulation by means of SimPARTIX®, a simulation method based on DEM which was developed by powder technology specialists at the Fraunhofer IWM. In this regard, for example, the influence of the filling speed or the filling shoe design on the filling results can be examined and optimized. In addition to measuring the required model parameters, the IWM experts develop specialized complex laws of interaction between powder grains, which have been customized for particular flow characteristics.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM