Residual stress analyses

Our goal is to provide our customers with components optimized for residual stresses.

We develop recommendations and concepts for component design, material application and manufacturing processes by determining production and application related residual stresses and evaluating them with regard to reliability, safety and service life. For this purpose, we take into account the underlying material microstructure, environmental degradations (for instance from hydrogen or corrosion) and manufacturing influences (e.g., due to welding, heat treatment and surface treatment).

We realize cost-effective measurement strategies for our clients that are adapted to individual problems. Here we guarantee a reliable evaluation and determination of residual stress conditions via the diffraction and mechanical methods at our disposal. Additionally, we carry out texture and phase analyses. Furthermore, we simulate and calculate residual stresses and manage effects on component applications, for example, with a specific focus on lifetime.

Based on our analyses and evaluations, we develop optimization concepts and strategies that deal with different material mechanisms:

- Microstructure optimization during heat treatment

- Machining-related strain hardening

- Wear and corrosion protection from the perspective of residual stress optimization

- Cracking due to hydrogen embrittlement

- Cold cracking after welding

- Hydrogen forced fatigue

- Changes to strength-related properties/deformability

- Stress corrosion cracking

- Changes in residual stresses and microstructure after surface treatments such as shot peening, hammering, roller burnishing, etc.

- Residual stress surface effects of machining processes such as grinding, turning, milling, etc.

- Unintended or misunderstood changes in the properties and functionality of manufactured and deployed components, such as distortion, cracking, fatigue, failure, corrosion.

- Development and changes of residual stresses during operation due to thermal, mechanical and chemical influences

- Improvement of manufacturing processes such as shaping, machining, post-treatment and joining

- Targeted formation of advantageous residual stresses during manufacturing

We prefer to carry out near-surface residual stress analyses by means of X-ray diffraction (XRD). This method is based on the determination of strain in the crystal lattice and is, therefore, suitable for (partially) crystalline materials. The components investigated range in size from millimeters to meters. The long-wave X-rays usually used have a low penetration depth of a few µm to roughly 10 µm. Larger depth ranges can be achieved by stepwise electrochemical ablation with subsequent measurements in each case. In these cases, the method is no longer non-destructive.

We investigate residual stresses on a wide variety of materials (metals, ceramics, composites, coatings). Our equipment allows, within certain limits, the determination of residual stresses strongly influenced by texture and coarse grain. For greatly deformed components and multiphase materials we evaluate via StressIWM, our own in-house developed software.

On-site measurements are possible via mobile diffractometers under consideration of radiation protection.

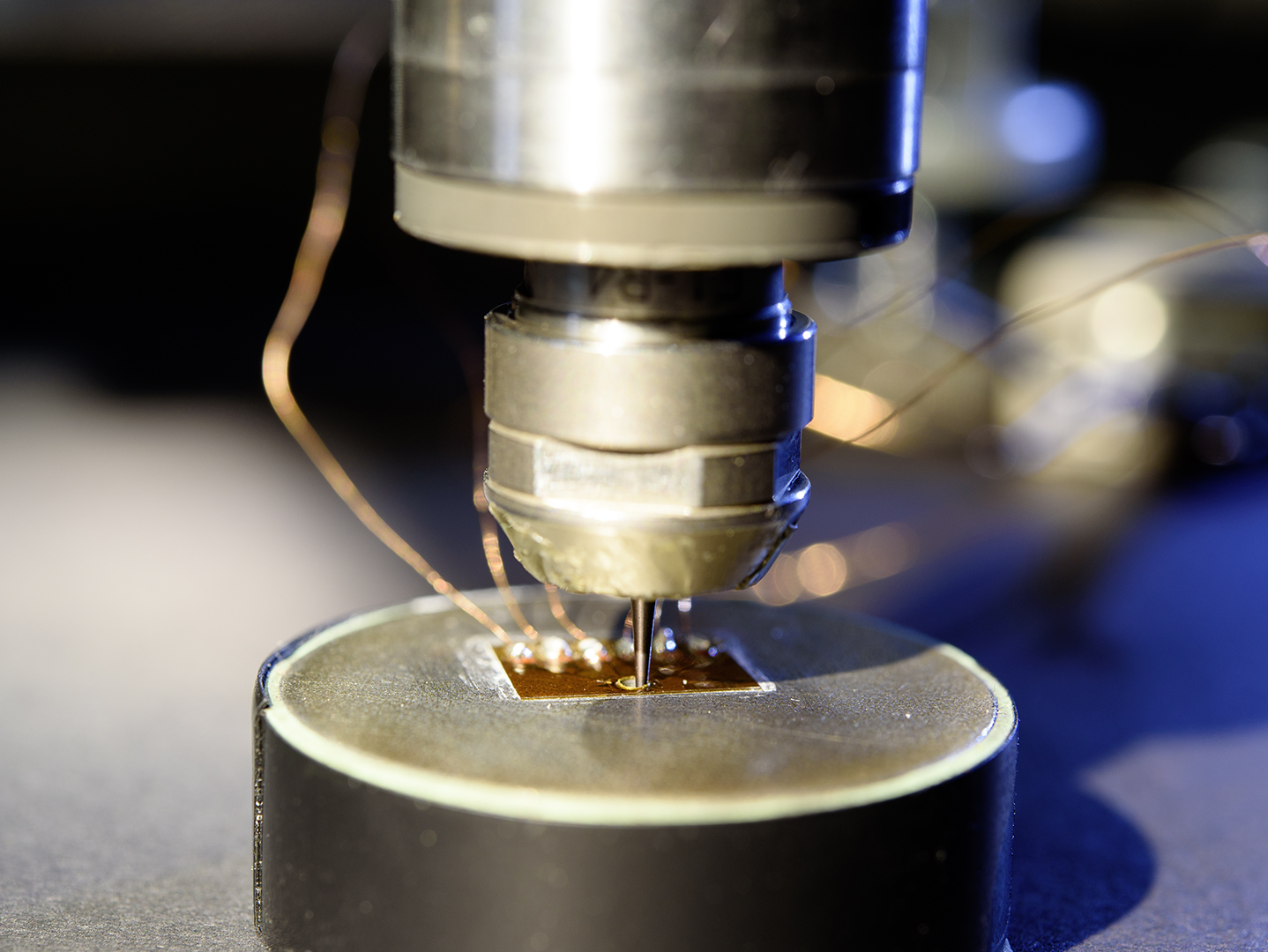

We offer point measurements with a small radius of 0.3 mm, which allows us to perform measurements in notches, including on large samples.

Our clients are spared complicated arrangements and sample shipments. For components with complex geometry, we offer a CAD routine to assess the accessibility of the measurement position via the classic sin2ψ method for advance determination of residual stresses.

The methods are constantly being refined and supplemented by new developments.

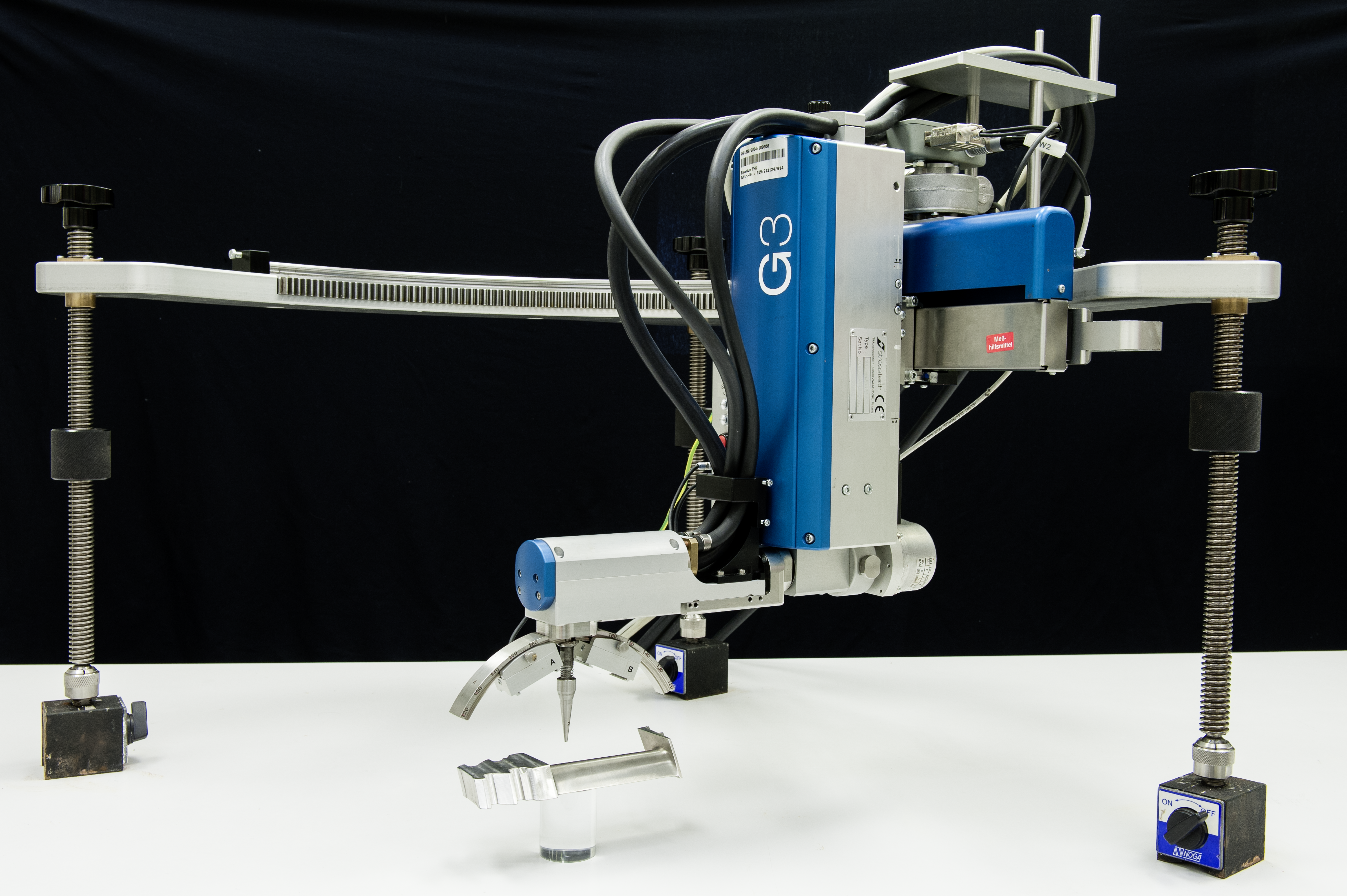

Via the newer cosα method, effective large-area mappings (0.3 x 0.3 m) are now possible at low cost. This allows short measurement times of up to 2 minutes, so that in-situ measurements on e.g., bend specimens are now possible. We are one of the few institutes able to offer such large-area mappings via robotic X-ray residual stress measurements.

From a depth of about 20 µm, residual stresses in surface layers can also be determined via the mechanical borehole method. For this purpose, the existing residual stress state is partially relieved step by step by high-speed milling of a blind hole or an annular groove, and the resulting strains are recorded by means of strain gauges. The original residual stresses can be calculated from the strain-depth curves. In this way, residual stress depth distributions up to about 1.8 can be determined.

Fraunhofer IWM has a number of different X-ray diffraction systems at its disposal. In addition to a stationary diffractometer, we have several mobile diffractometers for residual stress investigations on large components, as well as an automated 4-point bending device for the determination of special X-ray elastic constants. We work with location-sensitive X-ray detectors so that many measurements can be performed in a short time. Our diffractometer is equipped with a 2D detector for this purpose. For destructive residual stress measurements, we have a borehole instrument which operates according to ASTM E837-13a.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM