Hydrogen embrittlement in metals

Atomic hydrogen is able to significantly reduce the ductility of metallic raw materials. This can lead to the expected malfunction of components and is generally referred to as hydrogen brittleness. The diverse and distinct susceptibilities for hydrogen embrittlement in otherwise strong material properties limit the selection of raw materials.

Through various processes, hydrogen can penetrate into the raw materials; through loading with gaseous hydrogen and through electrochemical processes (e.g. corrosion or galvanic coating). The problem of hydrogen embrittlement in the traffic and energy sector is becoming increasingly important as hydrogen is viewed as an important energy carrier of the future. The associated development of new technologies to manufacture, distribute and use hydrogen as an energy supplier requires the qualification of available raw materials and those to be newly developed for these applications.

The Fraunhofer IWM supports its clients in selecting and qualifying raw materials and manufacturing procedures, assessing their lifetime expectancy and in cases of damage, identifying the causes of the component malfunction. Our employees have many years of experience in investigation and explaining the mechanisms of hydrogen brittleness and in the simulation of the underlying diffusion processes. Experimental equipment is available for the targeted loading of raw materials with hydrogen including simultaneous mechanical and thermal loading to determine the hydrogen content, to characterize the microstructure and to determine the hardness-relevant properties.

- Measurement of hydrogen diffusion constants and the determination of traps in metals

- Assessment of the effect of alloy composition on hydrogen embrittlement; microstructure analysis, fractography, mechanical in-situ experiments

- Establishment of design guidelines and operating life assessments for metal components used in a hydrogen environment

- Atomistic simulation of hydrogen bond energies within the crystal lattice, assessment of various traps

- FE modeling of diffusion and local enrichment of hydrogen during welding and heat treatment

- Damage analyses to identify component failure due to hydrogen

- Risk and life cycle assessment

Our laboratory equipment

- Modified permeation cells for the measurement of hydrogen diffusion coefficients dependent upon tensile stress and temperature

- Elecrochemical and pressurized gas hydrogen charging for defined hydrogen charging of materials

- Material qualification with in-situ hydrogen charging or after pre-charging

- Hot gas extraction to measure hydrogen, nitrogen and oxygen content in metallic materials (Eltra OH-900 and ON-900)

- Thermal desorption spectroscopy up to 1100 °C to determine binding energy

- High resolution SEM (Zeiss Supra 40VP with integrated EBSD system) for detailed analyses of the effect of hydrogen on fracture behavior

- Laboratory and on-location x-ray diffractometer to determine phase composition, texture and residual stress of crystalline materials

- Hollow sample test rigs for experiments with internal gas pressures up to 200 bar and adjustable test temperatures

Experimental investigations

- From March, 2019: Electric mechanical test machines with integrated high pressure autoclave (1000 bar) for:

- Slow tensile tests (SSRT, CERT) with optional cells for electrolytical in situ hydrogen loading, e.g. according to ASTM G 129

- Crack propagation and tiredness tests with optional cells for electrolytical in situ hydrogen loading

- Notched tensile test, e.g. in consideration of ASTM F 519 or DIN EN 2832

- As of mid-2017: Electrical mechanical test machines with integrated autoclave (1000 bar)

- Carrier gas hot extraction

- Measuring the total hydrogen content in metallic samples

- Test apparatus: Eltra OH-900

- Thermal desorption spectroscopy

- Infrared oven up to 900 °C

- Wire-wound tube oven up to 1100 °C

- Measurement of the proportion of diffusible hydrogen

- Measurement of trap binding energy

- Test apparatus: Bruker Phoenix G4 with mass spectrometer from the company InProcess Instruments

- Permeation tests

- Measuring the diffusion coefficients

- Trap density measurement

- Testing to DIN EN ISO 17081

- Microstructure and residual stress analysiseg. through:

Hollow samples – an alternative to autoclave technology

Tensile tests with hollow samples can deliver significant results for the evaluation of a material’s sensitivity to hydrogen. The samples have a through bore which is pressurized with a hydrogen containing gas mixture during testing. The significance of hollow sample technology is illustrated by current results of tensile tests on a pipeline steel. There is a considerable reduction of elongation at break/fracture strain through hydrogen embrittlement compared to reference tests in air. Tests with hollow samples are quicker, simpler and cheaper than tests in pressurized hydrogen autoclaves with full samples. Furthermore, they reflect the real/actual hydrogen gradient within a pipeline.

Simulation

- Simulation of temporal and locational hydrogen distribution regarding the diffusion and trapping behavior in components and component areas (e.g. in welding joins and edge layers)

- Models that predict the hydrogen-supported formation of cracks and calculate statistical stress limits for any component geometries

- Lifetime assessment for hydrogen-supported crack expansion

- Atomic simulation and binding energy of hydrogen in the crystal lattice and assessment of different trap areas

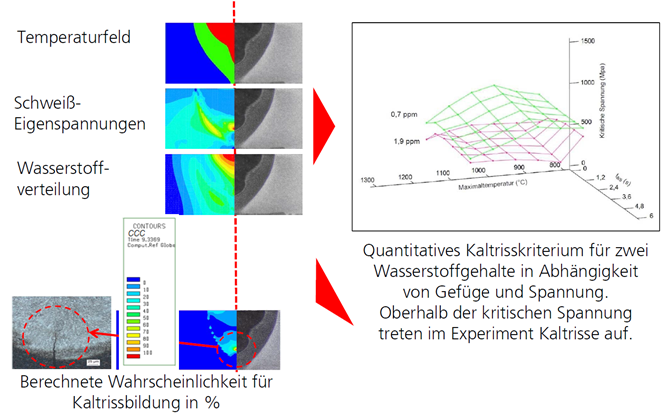

Calculation of hydrogen-influence cold crack risk

Using the numerical calculation of structures, residual stress and hydrogen diffusion when welding, it is possible to predict the cold crack resistance of complex components. Solutions allow users of thermal manufacturing processes, e.g. welding and heat treatment, the ability to address cold crack safety in the development phase when designing constructions. This takes place by coupling numerical simulation with experimentally determined risk criteria in consideration of process-typical loads.

Figure 1 shows a laser beam welding tube from high-strength steel, with which the cold crack probability was calculated from the numerical simulation of the temperature field, welding residual stress, and local hydrogen distribution. The calculation was based on a new methodology for determining quantitative cold crack criterion that was experimentally ascertained for the steel strength.

Detection of hydrogen in metal components using computer simulations

Since metal is “cooked”, rolled and later processed into sheet metal and components, the finest cracks and brittle areas can arise, leading to instability in the metal components. Atomic hydrogen is often at fault for this, as it moves through the metal and collects at imperfections or metal grain boundaries, thereby deteriorating the mechanical properties. The mechanism behind this is called hydrogen brittleness. Depending on load and outside influence, such imperfections may develop along fine cracks and can grow to a critical size - at which point the component breaks.

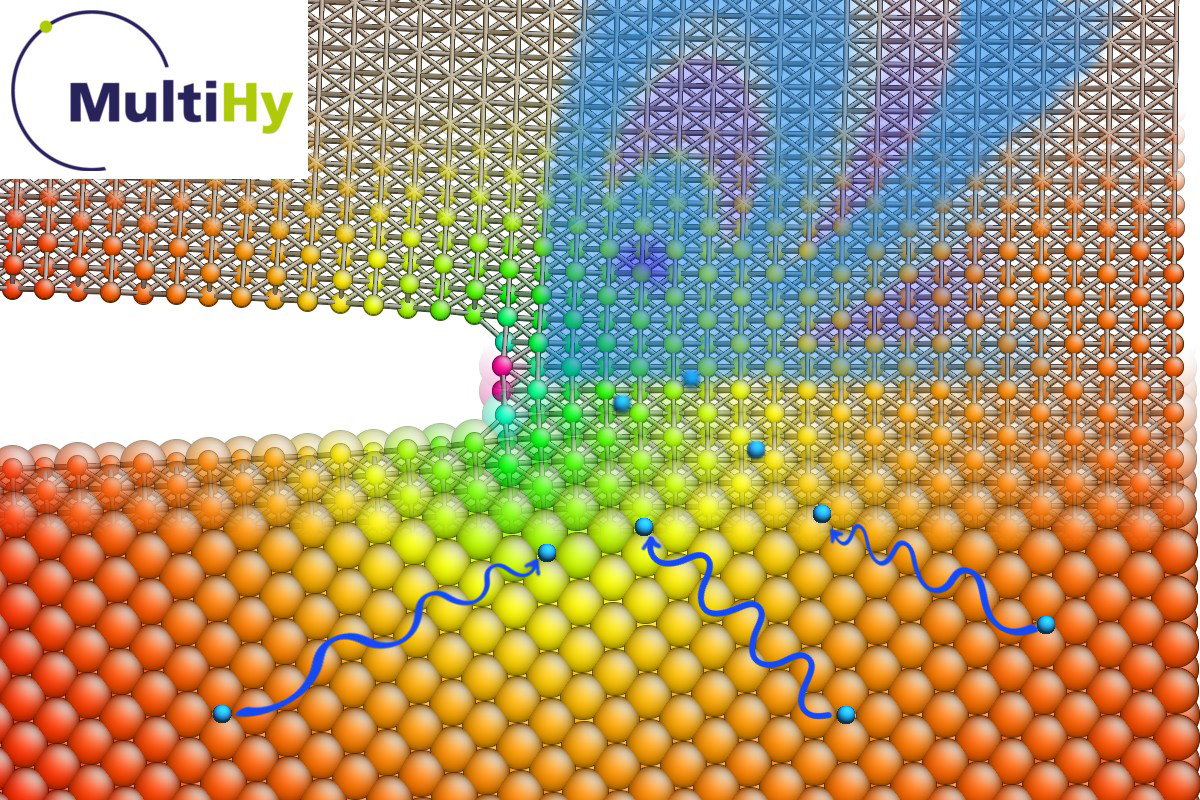

Previously, scientists analyzed how cracks form and progress in order to understand hydrogen brittleness. However, these mechanisms strongly depend on how hydrogen moves in the metal and how high it is concentrated at critical areas of crack formation. The MultiHy project therefore focuses on local conditions in crack formation such as hydrogen concentration, material tension, temperature, and mechanical loading. It is important to understand the movements of hydrogen in the metal depending on external factors and the material structure in different size scales. “We now want to carry out computer simulations over many size scales overall, from the behavior of atoms across several interim steps to the behavior of the overall component”, explains the project coordinator, Dr. Nicholas Winzer, regarding the special features of the project. Atomic information such as diffusion barriers, activation energy and impurities in the crystal lattice can now directly flow into the prediction of the component lifetime under its use conditions. “Using the simulations, we can predict with greater accuracy how susceptible a material or component is to hydrogen brittleness under realistic conditions”, says Dr. Matuous Mrovec, coordinator of the atomic simulations. Experiments using material samples supplied by the project’s industry partners also occur. The Fraunhofer IWM, together with its project partners, optimizes simulations using these results.

Eleven partners from research and industry are working out application-oriented, industrially relevant problems in the “Multiscale Modeling of Hydrogen embrittlement MultiHy” project, which is promoted as part of the European Commission’s 7th framework program. The UK, the Netherlands, Norway, Austria and Spain are represented alongside Germany. The project will span four years in total.

Publications

- Reichenbacher, A.; Fischer, C.; Schweizer, C.; Seifert, T., A finite element study on the influence of the hardening behavior on plasticity-induced fatigue crack closure, International Journal of Fatigue 158 (2022) Art. 106768, 11 Seiten Link

- Michler, T.; Elsässer, C.; Wackermann, K.; Schweizer, F., Effect of hydrogen in mixed gases on the mechanical properties of steels—theoretical background and review of test results, Metals 11/11 (2021) Art. 1847, 11 Seiten Link

- Michler, T.; Schweizer, F.; Wackermann, K., Review on the influence of temperature upon hydrogen effects in structural alloys, Metals 11/3 (2021) Art. 423, 16 Seiten Link

- Michler, T.; Schweizer, F.; Wackermann, K., Review on the influence of temperature upon hydrogen effects in structural alloys, Prime Archives in Material Science: 3rd Edition; Khan, M. I. (Ed.); Vide Leaf, Hyderabad, India (2021) 33 Seiten Link

- Michler, T.; Wackermann, K.; Schweizer, F., Review and assessment of the effect of hydrogen gas pressure on the embrittlement of steels in gaseous hydrogen environment, Metals 11/4 (2021) Art. 637, 15 Seiten Link

- Michler, T.; Bruder, E.; Linder, S., Hydrogen effects in X30MnCrN16‐14 austenitic steel - Einfluss von Wasserstoff in dem austenitischen Stahl X30MnCrN16‐14, Materialwissenschaft und Werkstofftechnik - Materials Science & Engineering Technology 51/4 (2020) 531-538 Link

- Casajus, P.; Winzer, N.; Intergranular stress corrosion crack propagation in rolled AZ31 Mg alloy sheet; Materials Science and Engineering A 602 (2014) 58–67 Link

- Winzer, N.; Höpfel, H.; Casajus, P., Development of a generalised understanding of environmentally-assisted degradation of magnesium-aluminium alloys, in Proc. of Magnesium Technology 2014; Alderman, M.; Manuel, M.V.; Hort, N.; Neelameggham, N.R. (Eds.); John Wiley & Sons, Inc., Hoboken, NY, USA (2014) 365-372 Link

- Winzer, N., Mrovec, M.; Di Stefano, D.; Katzarov, I.; Paxton, A., Industrially-relevant multiscale modelling of hydrogen assisted degradation, Hydrogen-Materials Interactions: Proceedings of of the 2012 International Hydrogen Conference ICH 2012; Somerday, B. ; Sofronis, P. (Eds.); ASME Press, New York, NY, USA (2014) 737-745 Link

- Winzer, N.; Khader, I.; Hydrogen diffusion and trapping in bodies undergoing rolling contact; Wear 303/1-2 (2013) 451-458; 364/2013 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM