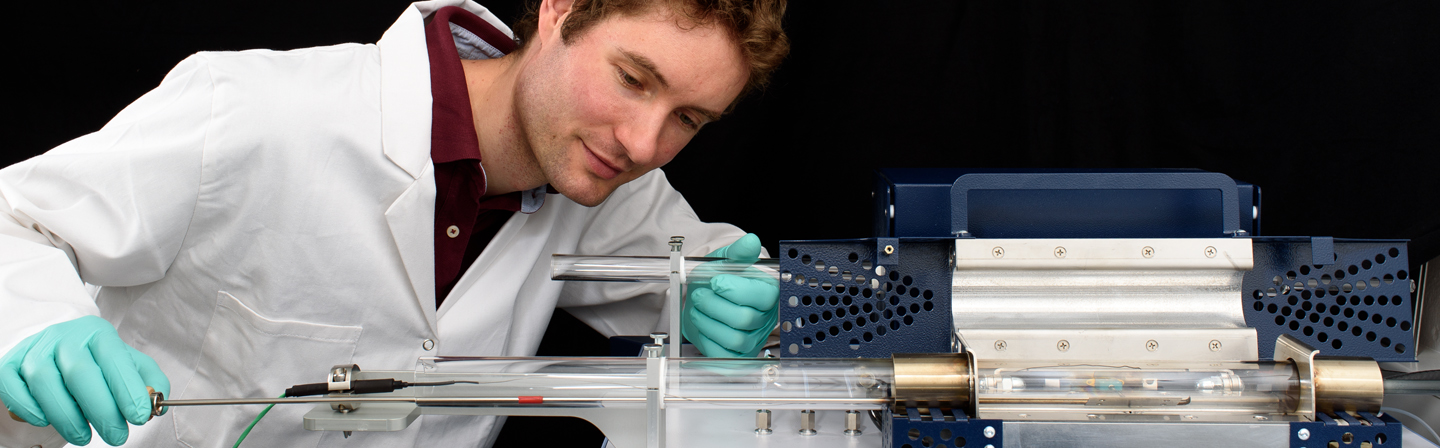

Microstructure and Residual Stresses

We investigate the effect of manufacturing processes and operational loads on the microstructure and the internal stress in materials and components. A particular focus lies on the identification of the combinatory degradation mechanisms of high temperature corrosion, stress corrosion cracking and hydrogen embrittlement. This is done using experimental methods, such as permeation tests with superimposed mechanical loads, and numerical methods, such as the simulation of microstructure and internal stress formation. This lays the basis for the appropriate selection of materials or the optimization of materials and processes and the prediction of operational behavior.

What we offer

- Analysis and evaluation of material microstructures due to production

- Thermodynamic simulations to predict microstructure evolution

- Elucidation of microstructure property relationships

- Experimental determination, simulation and evaluation of residual stresses in components

- Characterization of materials in contact with hydrogen and analysis of degradation mechanisms

Reasons for collaboration

- »Anomalies« in production, test operations or in use (e.g. reductions in strength, crack formation, corrosion, surface defects)

- Cases of damage

- Compliance with specifications for raw materials and components and ensuring standards

- Clarifying property changes in operation due to external factors (thermal, mechanical, chemical or coupled)

- Questions of quality assurance when converting production processes

- Assessing new raw materials regarding manufacturability, corrosion, long-term stability, strength and dimensional accuracy

- Targeted generation of favorable properties in manufacturing

- Need for input data for material simulations

- Need for quantitative evaluations of raw materials (e.g. pore proportion, phase proportion, structure morphology, texture and raw material gradients)

- Information on quantitative microstructure property relationships

Examples

- Basis for decisions to use (replacement) materials

- Approaches for increasing the performance of the materials used (e.g. by pre-treatment, heat treatment, coating, etc.)

- Procedures to improve manufacturing steps (welding, surface treatment, heat treatment)

- Suggestions for component optimization

- Causes of damage and damage appraisals

It’s worth getting in touch with us

- Our experienced staff provide the results of analysis and research efficiently, providing a reliable basis for our clients to take decisions

- Our expertise in material microstructures, damage mechanisms in materials and components and residual stress allows us to consider problems holistically and deliver sustainable solutions

- Our equipment allows us to investigate a wide variety of materials (ceramics, metals, layers, composites)

- At the institute, we have a large pool of experts in a wide variety of specialist areas of material science. This leads to quick and efficient solutions for our clients

- Our range of equipment and facilities allows us to carry out an efficient combination of measurement and analysis procedures based on the needs of the client

- We have our own sample production facilities and can handle large components

Contact us! Together we'll find a customized solution for the challenges you face.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM