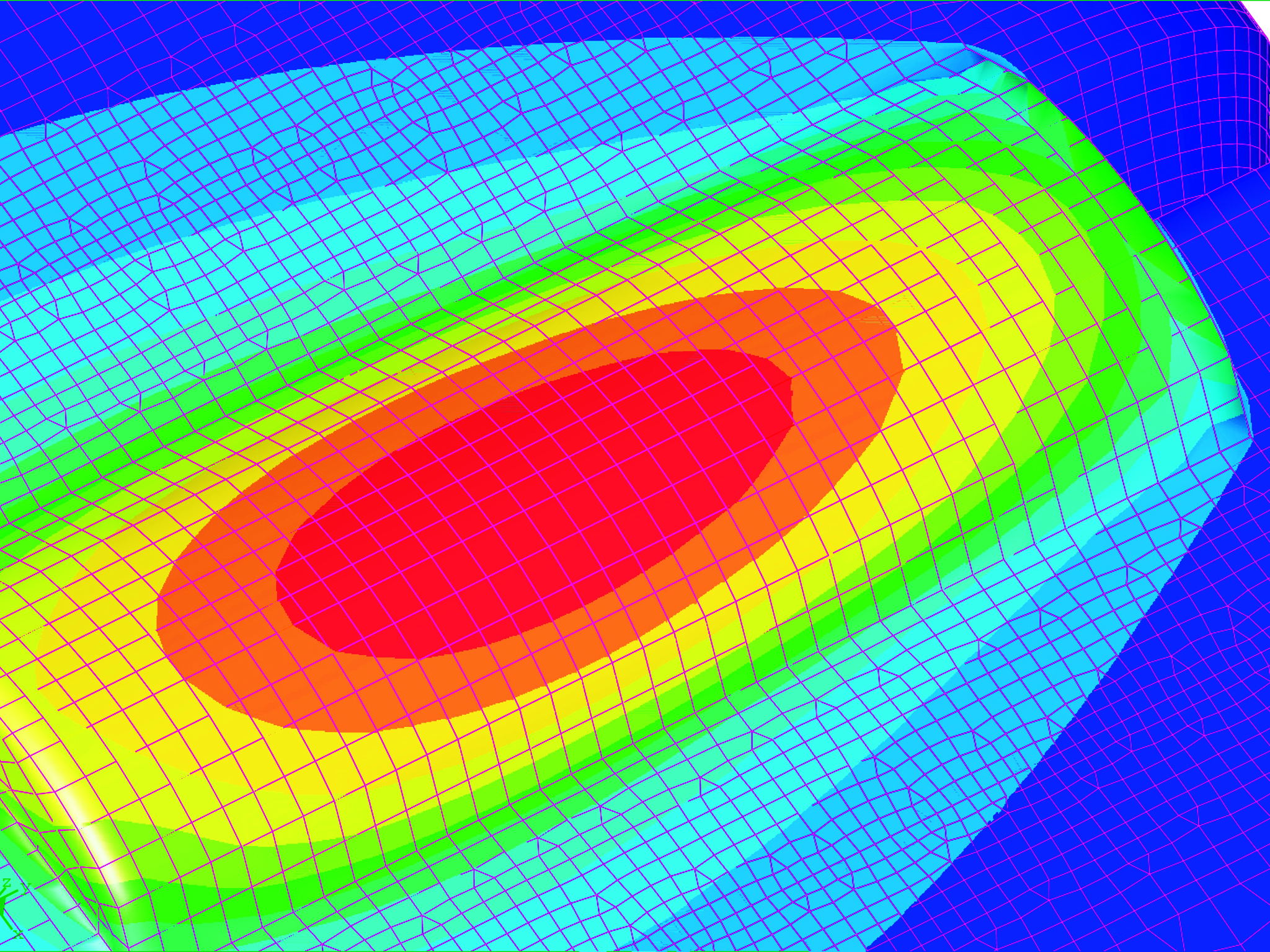

The heat treatment of metals is an important means of creating a favorable microstructure and residual stress within a component. A movable inductor is often used to heat up the components. The experimental optimization of the treatment parameters is time-consuming and costly, particularly for larger components such as wind turbine bearings. Thanks to our effective mapping techniques and an enhanced simulation environment, we are able to economically and correctly predict the microstructural and residual stress development and better comprehend the underlying processes.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM