We make friction and wear of materials and components calculable: with our experiments we examine the tribological effects of materials and their surfaces.

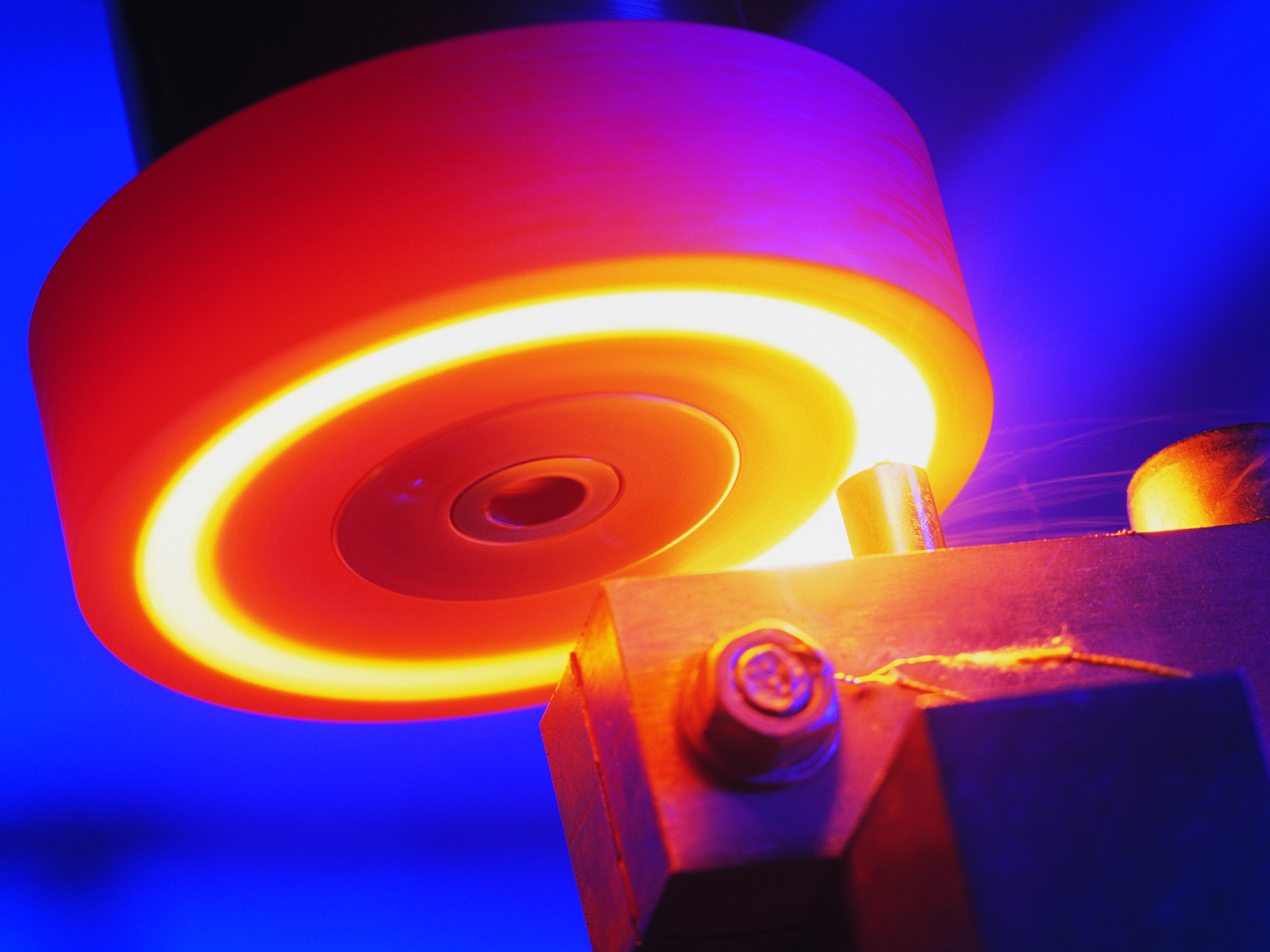

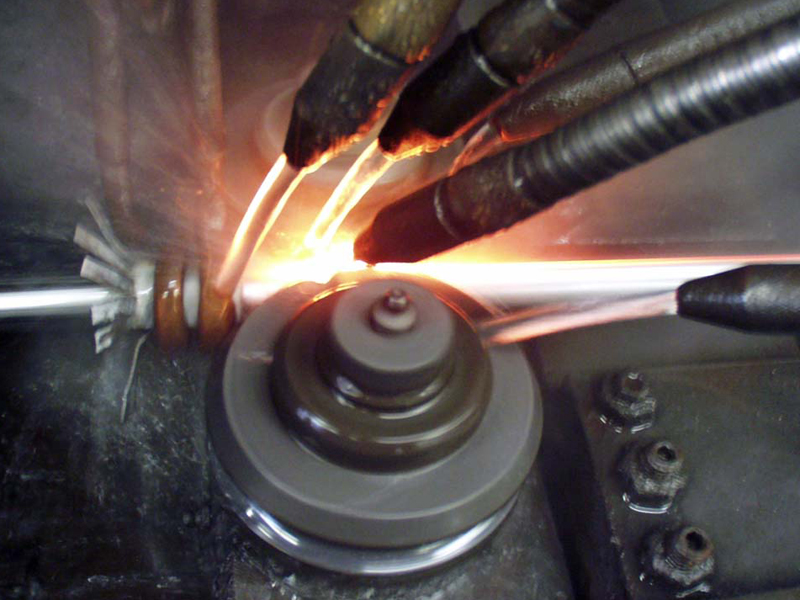

High operating temperatures are ubiquitous: they can be found in drive units, in industrial production processes like hot forming and machining and in energy production. The challenge comes in cases in which high temperature liquid lubrication is not possible, yet components are still expected to function reliably and for an extended period of time.

High temperatures often inhibit the efficiency of systems under high frictional stress. Moreover, high temperatures are not only generated by the environment, but also by friction heat.

Different material classes – polymers, metals, ceramics and coatings – react very differently to increased operational or friction temperatures: While polymers and some coatings mostly dissolve thermally, other materials react chemically with the atmosphere or are plastically deformed within tribological contacts.

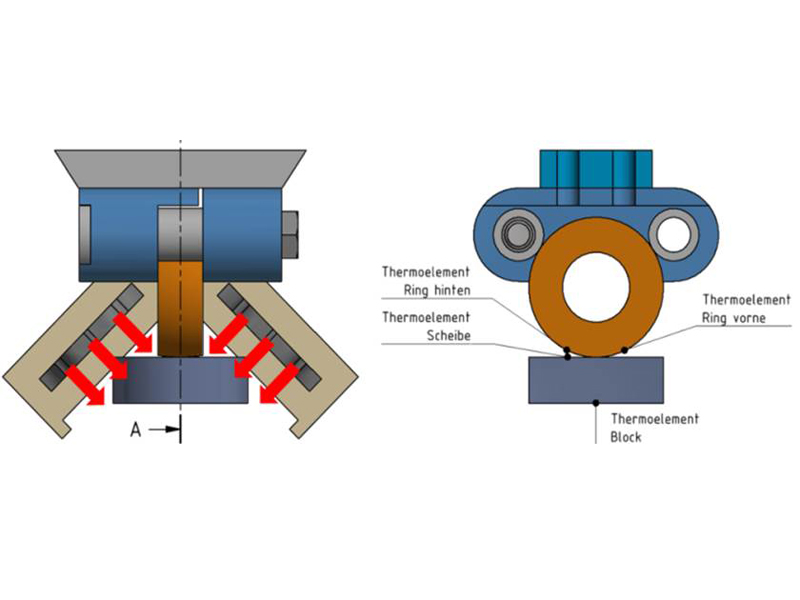

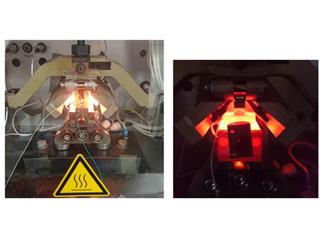

It is a special challenge to construct experimental tests in which thermal effects – including interaction with the atmosphere – can be simulated in an application-related manner. Only then can truly relevant statements about the tribological behavior of systems in increased temperatures be generated.

At the Fraunhofer Institute for Mechanics of Materials IWM, It is our job to investigate the tribology of materials and components at high temperatures in order to contribute to the description and improvement of a given system’s efficiency, reliability and life span.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM