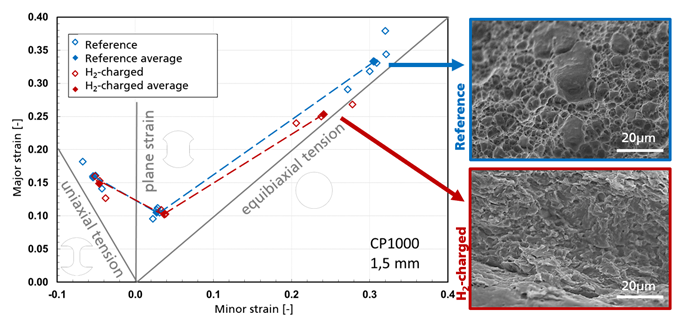

Advanced high-strength steels are increasingly used in the automotive industry to reduce vehicle weight and increase safety. Electrochemical coating processes and corrosion can lead to hydrogen absorption in the component. When forming sheet metal, various, often multi-axial stress states arise in the component. These can have different effects on the susceptibility to hydrogen embrittlement. Uniaxial and multiaxial stress states can be represented by Nakajima tests. Experiments on electrochemically pre-charged specimens have shown that after the evaluation of the forming limits according to DIN EN ISO 12004-2, the equibiaxial stress state in particular shows a susceptibility to hydrogen. However, a reduction in the elongation at fracture caused by hydrogen could also be determined in the uniaxial stress state and in the plane strain state, whereas the evaluation of the forming limits was not affected. It is therefore important to examine material properties with hydrogen charging under operationally relevant stress states and to use suitable evaluation methods.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM