Tribological and Functional Coatings

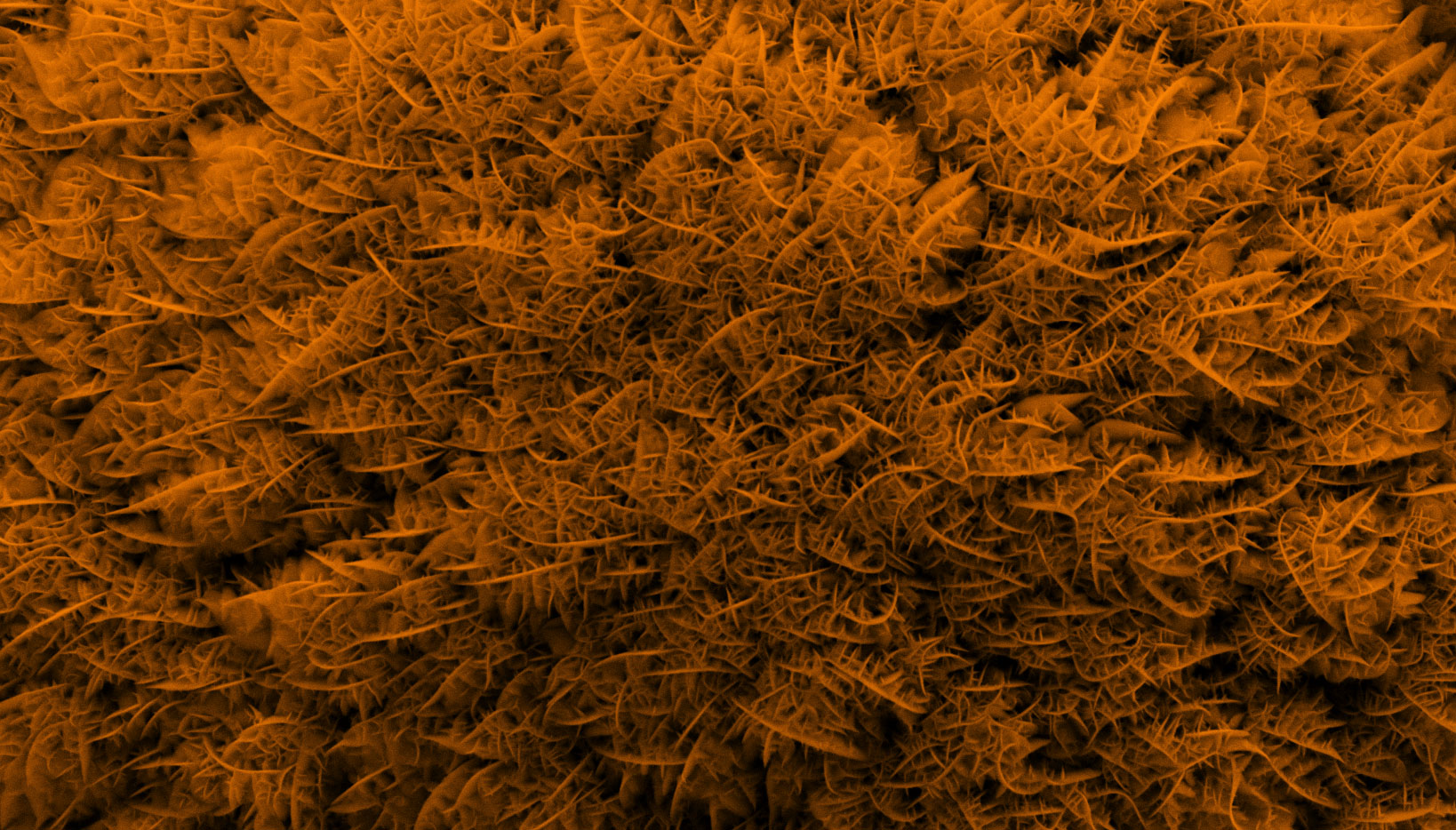

One of the keys to reducing friction and protecting against wear is to coat components with diamond-like carbon (DLC) or hydrocarbon layers. Further functions of components like reflection, sensors and barrier effect are adjusted via PVD coatings. With the help of in-built elements that modify networks into the plasma coating, we can create optimum lubricant wettability and prevent unwanted adhesion. Our process technology, with the aid of plasma diagnosis, is capable of controlling both the inherent and the topographical properties of amorphous hydrocarbon layers as well as binary and ternary hard materials.

What we offer

- Deposition of hard, thick DLC layers via high rate CVD

- Metallic, carbidic, nitridic and oxidic functional coatings, MAX phases

- Coating of plastics and molds

- Production and qualification of in-situ structured coatings

- Mechanical and tribological characterization of thin films

- Thin film sensor technology

- Electrically high-insulating coatings

- Coatings for diamond heteroepitaxy

- (High temperature) corrosion protection coatings

- Development and characterization of hydrogen diffusion barriers

Contact us! Together we'll find a customized solution for the challenges you face.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM