Measuring the morphology of granules when spray drying powders

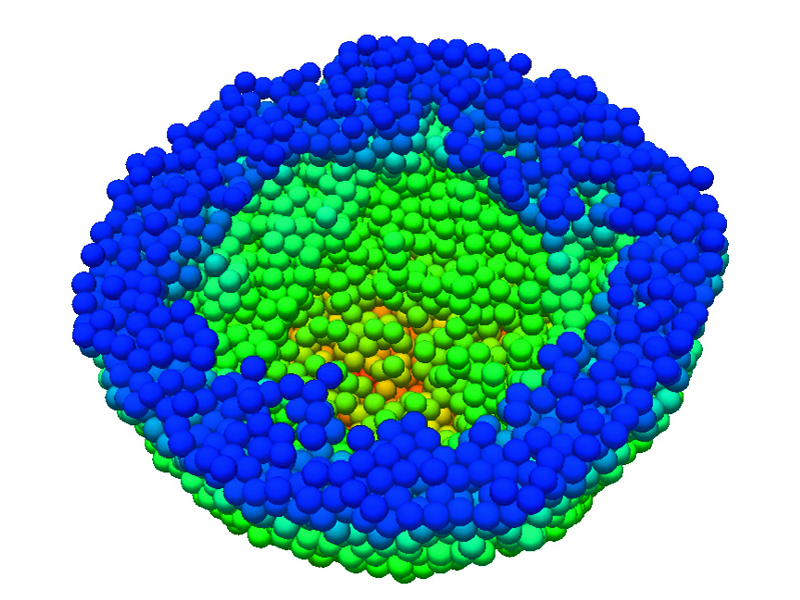

In the ceramics industry spray drying is an important process for converting fine primary powders into bigger granules with better transport properties. To achieve a high quality end product requires good attributes, specifically in reference to the handling and compaction of the granulate. For this reason, the granules should preferably be spherical and possess a homogeneous density. At the Fraunhofer IWM, material models are linked using the discrete element method (DEM) and numerical flow simulations are used to investigate granule formation. This enables us to simulate the evolution of granular materials through drying individual droplets. As a result, the correlation between parameters such as the droplet’s surface tension or the surface energy of the primary powders and the shape of the resulting granules are available for process optimization.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM