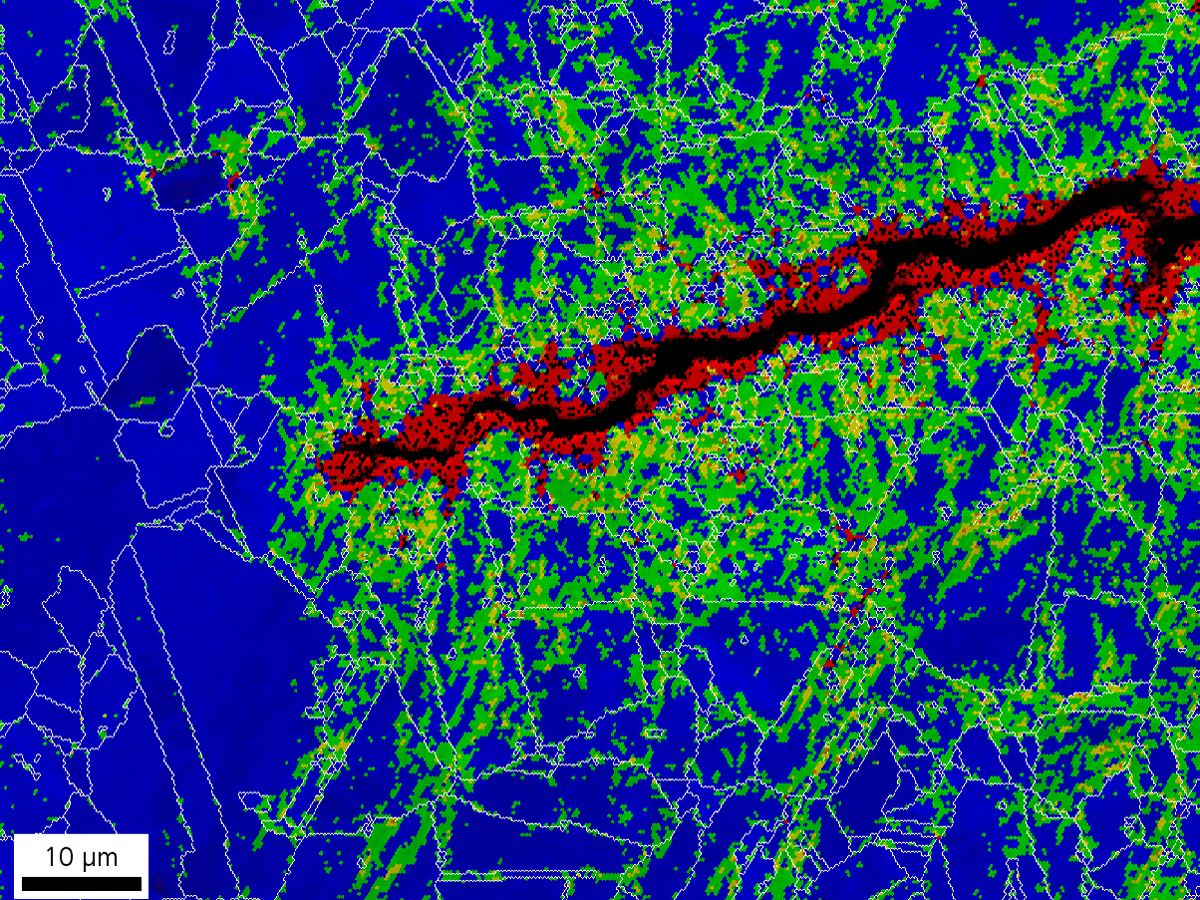

Thermal and mechanical loading can lead to the transcrystalline and intercrystalline cracks and creep pores forming and growing. Oxidation and corrosion processes can also damage the material and change the microstructure to such an extent that the mechanical properties are significantly altered. When developing material models and designing components, it is therefore important to understand which deformation and damage mechanisms dominate during operation and how the mechanisms interact.

Identification of deformation and damage mechanisms

Services

Fracture mechanics based short crack models are mainly used in a methodical fashion. These are based on an analysis of the time and temperature dependent crack tip fields. Research and development focuses include:

- Handling of variable amplitudes and real operating loads under variable thermocyclic loading

- Consideration of the crack length dependent crack closure effects in areas of both physically short and long cracks

- Consideration of thermally and mechanically induced stress gradients

- Consideration of creep fatigue damage in areas of both physically short and long cracks

- Dealing with manufacturing related defects (e.g. in the case of additively manufactured materials)

- Evaluation of environmental influences (e.g. hydrogen, oxygen) and extension of the existing lifetime concepts while taking into account the influence of the environmental medium on the fatigue damage

- Mechanics of materials based development of lifetime concepts for evaluations concerning failure probability of components under consideration of micro and defect structures

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM