Evaluation of new CuSn-based coating systems

Nickel coatings are used in a wide range of applications because they exhibit good corrosion resistance and certain properties can be specifically adjusted, such as hardness or gloss level. However, their use is problematic because nickel coating systems can trigger contact allergies while nickel salts have to meet increasingly stringent requirements as production materials. In a project funded by the state of Baden-Württemberg, the Fraunhofer IPA is developing electroplated copper-tin layers that are as environmentally compatible as possible both in production and application. The microstructure and properties of the coatings are being investigated at the Fraunhofer IWM.

A phase analysis using X-ray diffraction was used to determine a relationship between the chemical and phase composition of the layer, with δ-bronze, η-bronze and elemental tin being analyzed, depending on the Cu content. In particular, elemental tin should be avoided due to its poor physical and mechanical properties.

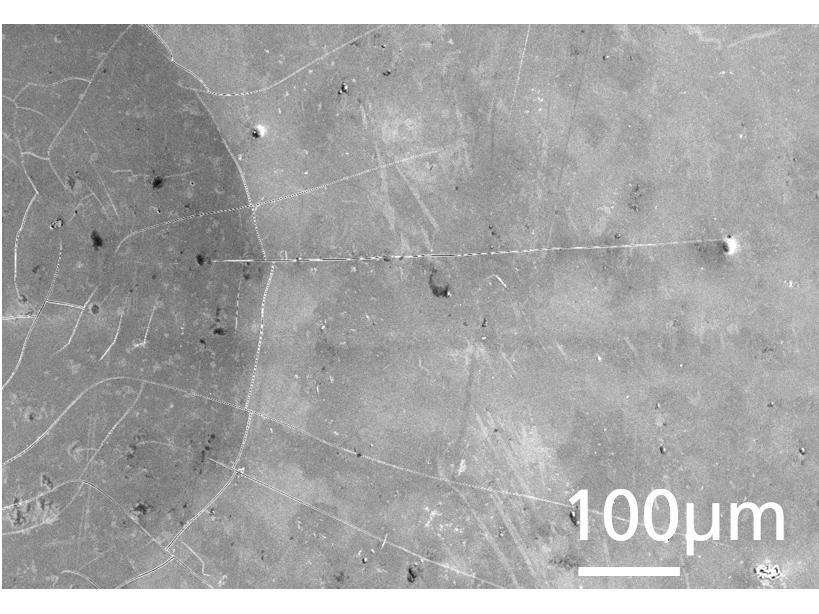

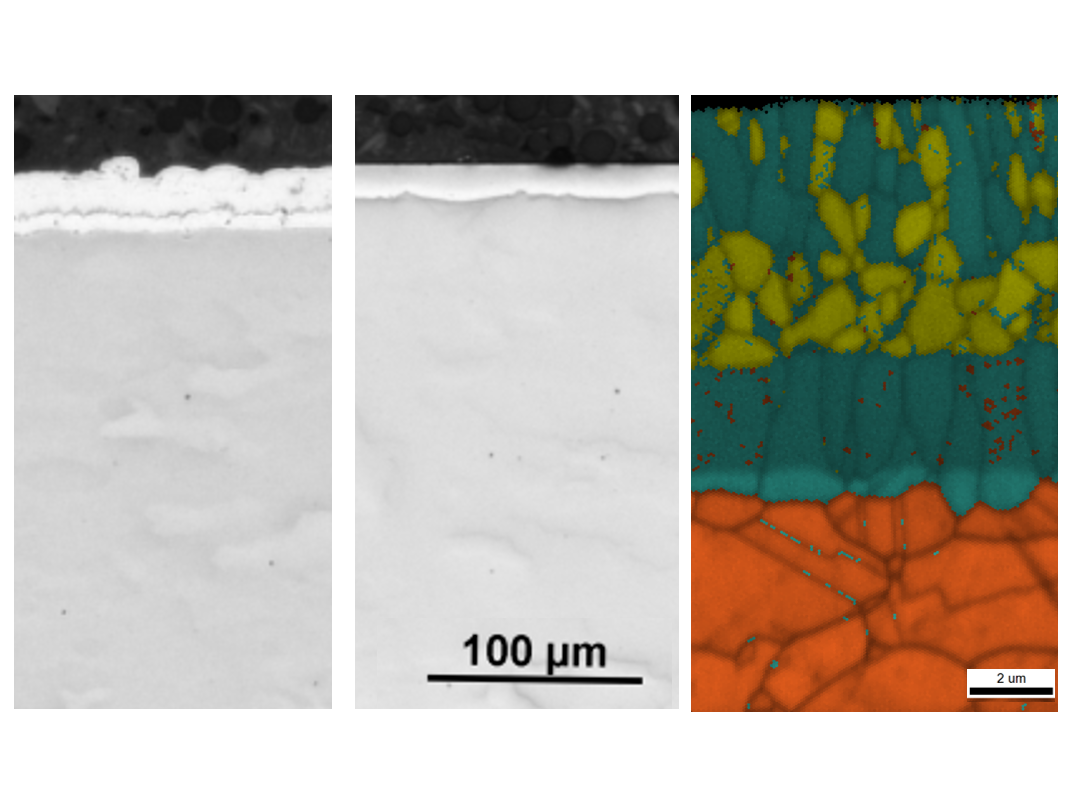

Figure 1 shows (left and center) that, depending on the electrolyte composition, both matte (uneven on the microscale) and shiny (relatively flat on the microscale) coatings can be produced. The mechanical properties are analyzed by means of nanoindenters. By means of ball indentation tests and subsequent optical analysis, cracking and possible spalling of the coatings under different loads are investigated. Figure 2 shows an example of a brittle layer after ball indentation tests.

The long-term durability of the CuSn coating system on brass and steel substrates is analyzed in aging tests. Figure 1 on the right shows the result of a combined analysis of electron backscatter diffraction (EBSD), elemental analysis (EDX) and X-ray diffraction (XRD) for local identification of the individual phases, here after artificial aging. Separation of phases in the layer is observed at temperatures of 400°C. Even if the coatings are not used at these high temperatures, the thermodynamic stability of the coating-substrate system can be evaluated by aging tests at different temperatures.

Back to Assessment of Materials and Lifetime Concepts Highlights

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM