Detecting hydrogen in metal components with computer simulations

Even during production, when the metal is »cooked,« rolled and later processed into sheet metal and components, the finest cracks and brittle areas arise that can make metal components more unstable. Atomic hydrogen is often to blame for this, as it moves through the metal and collects at imperfections or metal grain boundaries, thereby diminishing the mechanical properties. The mechanism behind this is called hydrogen embrittlement. Depending on the load and outside influence, such imperfections develop at fine cracks that can grow to a critical size – the component breaks.

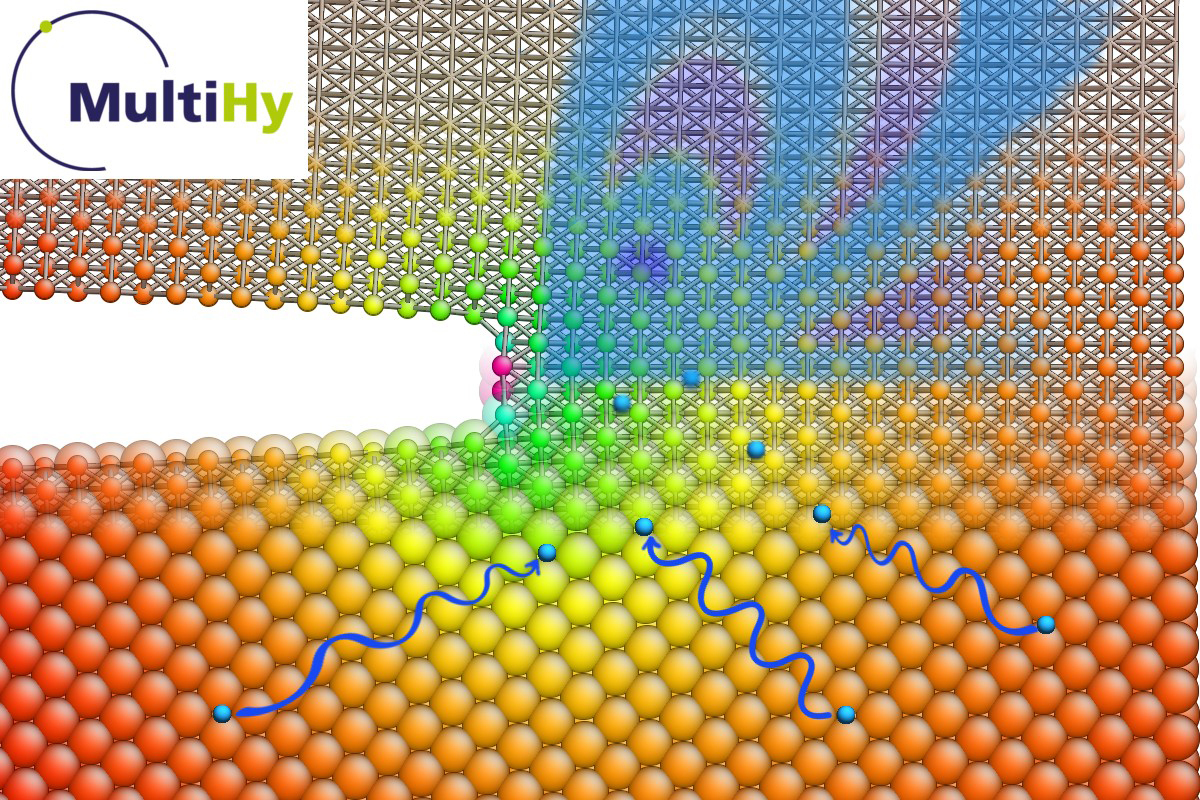

Previously, scientists have analyzed how cracks form and how they progress in order to understand hydrogen brittleness. However, these mechanisms depend heavily on how the hydrogen moves in the metal and how high its concentration is at critical places of crack formation. The MultiHy project therefore focuses on local conditions in crack formation such as hydrogen concentration, material stresses, temperature, and mechanical loading. It is important to understand the movements of hydrogen in the metal depending on external factors and the material structure in different size scales. »We now want to carry out computer simulations over many sizes overall, from the behavior of atoms across several interim steps to the behavior of the overall component.« explains the project coordinator, Dr. Nicholas Winzer, with regard to the special features of the project. Atomic information such as diffusion barriers, activation energy and impurities in the crystal lattice can now directly flow into the prediction of the component lifetime under its conditions of use. »Using the simulations, we can predict with greater accuracy how susceptible a material or component is to hydrogen embrittlement under realistic conditions.« says Dr. Matuous Mrovec, coordinator of the atomic simulations. Experimental investigations of material samples supplied by the project’s industry partners are also being carried out. The Fraunhofer IWM, together with its project partners, optimizes simulations using these results.

Eleven partners from research and industry have been working out application-oriented, industrial problems in the »Multiscale modeling of hydrogen embrittlement MultiHy« project, which is funded under the European Commission’s 7th framework program. The UK, the Netherlands, Norway, Austria and Spain are involved alongside Germany.

Back to Assessment of Materials and Lifetime Concepts Highlights

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM