PFAS substitution in tribological systems / 2026

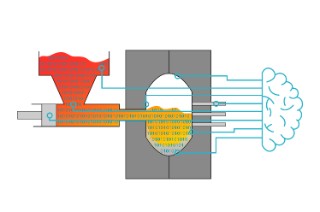

Ways to replace PFAS in systems subject to friction and wear

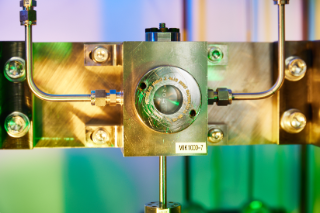

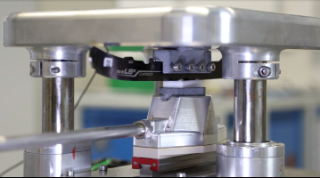

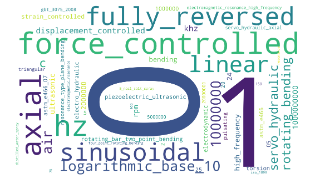

Scientists at Fraunhofer IWM have developed and tested a substitution chain for lubricants and seals containing PFAS in a project funded by the state of Baden-Württemberg and a Fraunhofer project. This allows suitable PFAS-free materials solutions to be efficiently identified and evaluated.

more info Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM