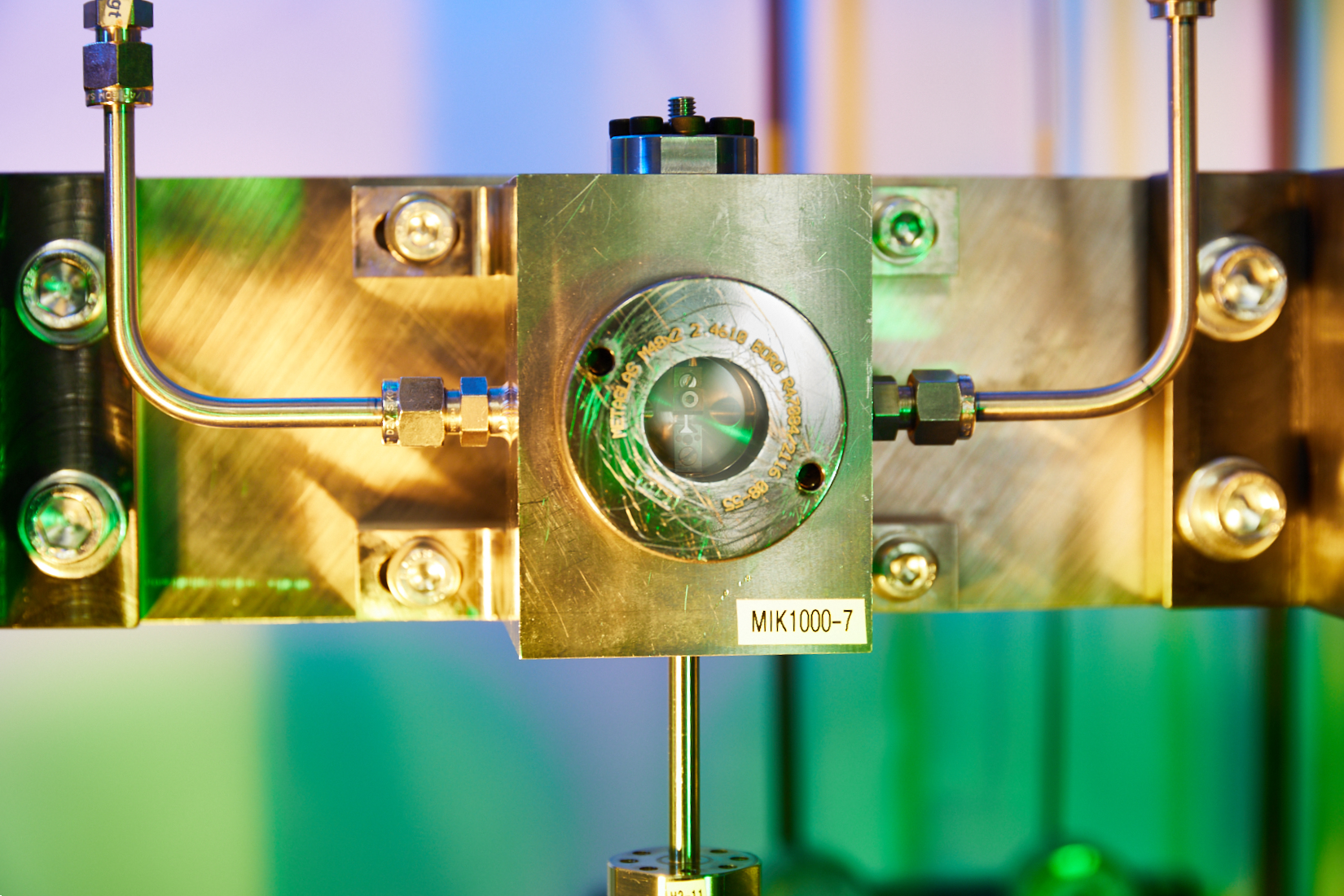

Mechanical damage to materials in contact with hydrogen poses considerable materials technology challenges in terms of reliability and service life for components such as pipes, storage tanks, valves, and compressors. With a novel high pressure hydrogen gas chamber for micromechanical testing, Fraunhofer IWM now has new opportunities to investigate the influence of hydrogen on materials behavior at the microscopic level. This annex enables rapid and cost-effective determination of the effects of hydrogen on mechanical properties and thus better qualification and selection of materials suitable for use in hydrogen-containing environments.

From a materials science perspective, the microscale with sample cross sections typically measuring 400 μm × 200 μm plays a decisive role for materials: Here, the distribution of pores, foreign phases, grain boundaries, dislocations, atomic defects, grain sizes, and grain orientations in materials structures are decisive factors for materials properties. Micro samples provide insights into fundamental mechanisms such as crack initiation and propagation as well as stress induced microstructural and phase transformations. This allows macroscopic failure events to be traced back to their microscopic causes. The small samples make it possible to test both extremely small components and local features in larger components.

Application examples

Via the extraction of micro samples from different zones of weld seams in components, areas in the materials structure that are susceptible to hydrogen embrittlement can be identified. This approach shows how different areas of the heat-affected zone react differently under the influence of hydrogen and supports the development of less conservative and thus more cost-effective design guidelines for components that are exposed to high pressure hydrogen.

The mechanical properties of thin-walled components in the main stress direction can only be determined using micro samples. Testing using micro samples enables more reliable design decisions resulting in safer, lightweight hydrogen-powered systems.

Thin film-based hydrogen membrane sensors, which are critical for leak detection, can be mechanically tested using micro specimens to evaluate their response sensitivity and durability under high pressure hydrogen exposure. In addition, micro specimens taken from the sensor membrane itself can be examined for their potential sensitivity to hydrogen embrittlement.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM