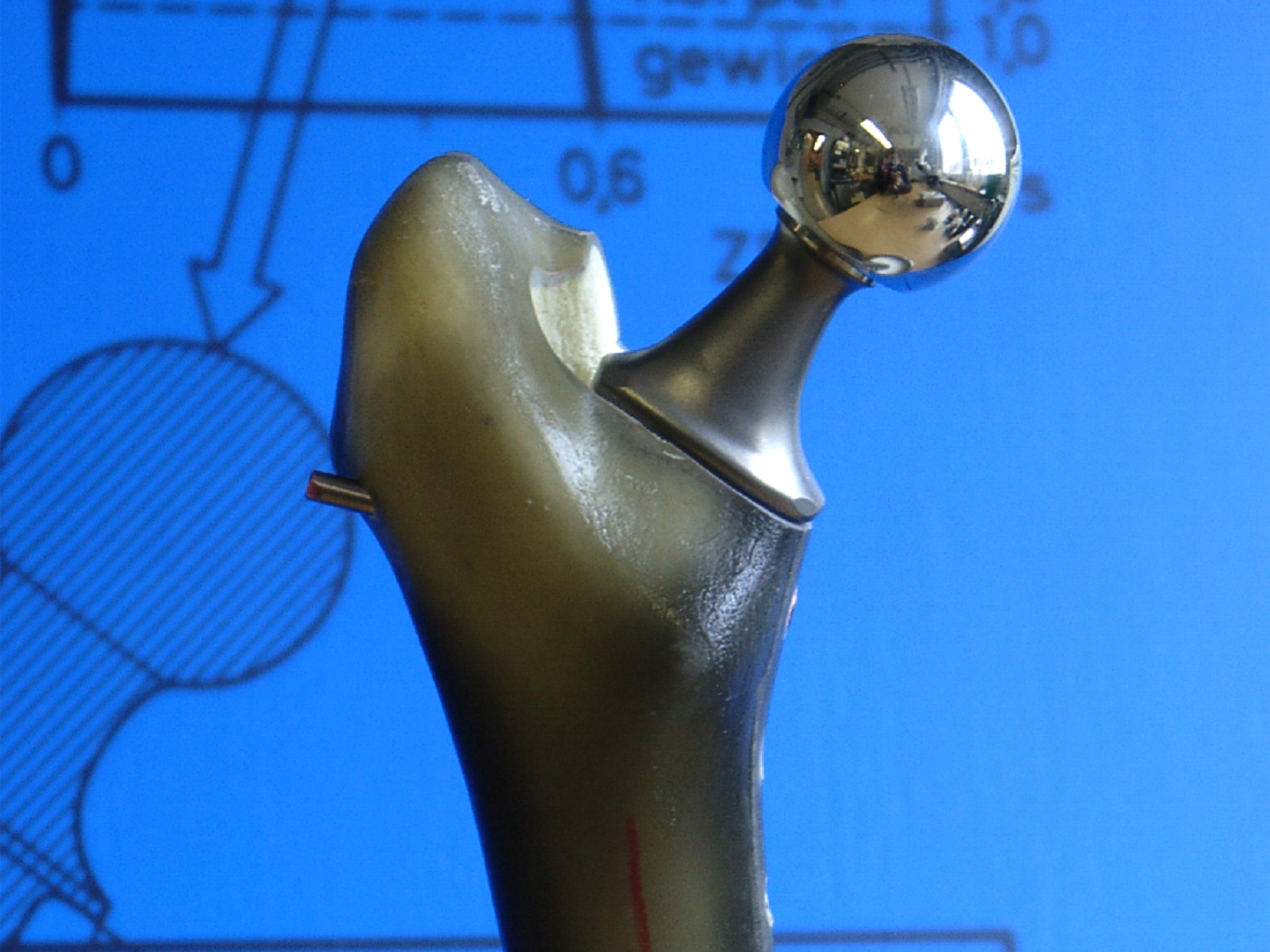

Hip joint prostheses, bone cements and dental implants in patients must survive several million load cycles without failure due to fatigue. Bone cement should have no critical creep deformation under load. The mechanical properties of resorbable osteosynthesis plates should change during the removal process in a defined way. A micro bone screw should quickly and definitely “grip” when screwed into the bones.

Non-woven fabrics made of electro-spun ultra-thin fibers or complex generatively manufactured structures have been the subject of growing interest in recent years because of their suitability as scaffolds for tissue engineering. These scaffold materials must have suitable mechanical properties for successful deployment.

With investigations into the reliability of biomedical materials and implants (e.g. regarding fatigue strength, quasistatic strength and creep resistance), our working group contributes to their safe use.

Reliability and operational behavior of biomedical materials and implants

Completely recyclable, lightweight, single Component Composite Material for Injection-Molded Components

In cooperation with the FMF Materials Research Center at the University of Freiburg and the polyolefin manufacturer LyondellBasell, the Fraunhofer IWM has produced and qualified a sustainable, all-PE single component composite. The reinforcing fiber structures are also made of PE and form during injection-molding… [more Info]

Design of oder-induced malfunction detection in plastics

Some safety-relevant components made of plastic cannot be examined with conventional methods, because they are difficult to access or have difficult dimensions. This can be remedied with olfactory, i.e. odor-induced, tests for detecting cracks. Our research project thus fills a gap with a particularly powerful method using human and also technical sensors. Applications such as the control and monitoring of protective helmets for sports, multi-layer walls of vessel systems and pressure hoses are conceivable.

Properties and operational behavior of dental substitute materials

Dental composites have to meet mechanical, chemical, technical processing and increasingly aesthetic requirements, among others. In addition to the tests described in the current standards, we develop methods that show the abrasion resistance and polishability of materials, determine volume and temperature behavior during hardening processes, and analyze the tension development of dental composites under light-curing or water intake, for example. Sealants or adhesives can be tested using proprietary methods in a mini-tensile test or shear test.

Fibers, hydrogels and nonwovens in medical technology

Besides the production of electro-spun “non-wovens”, our group focuses on the mechanical properties of nonwovens and individual fibers. Experimental studies on the strength of individual fibers or the orientation dependency of the mechanical properties of nonwovens are supplemented with mechanical models, which can simulate transport processes (cell seeding, nutrient intake) and mechanical stimuli on cells in scaffolds, for example.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM