Lifetime Concepts and Thermomechanics

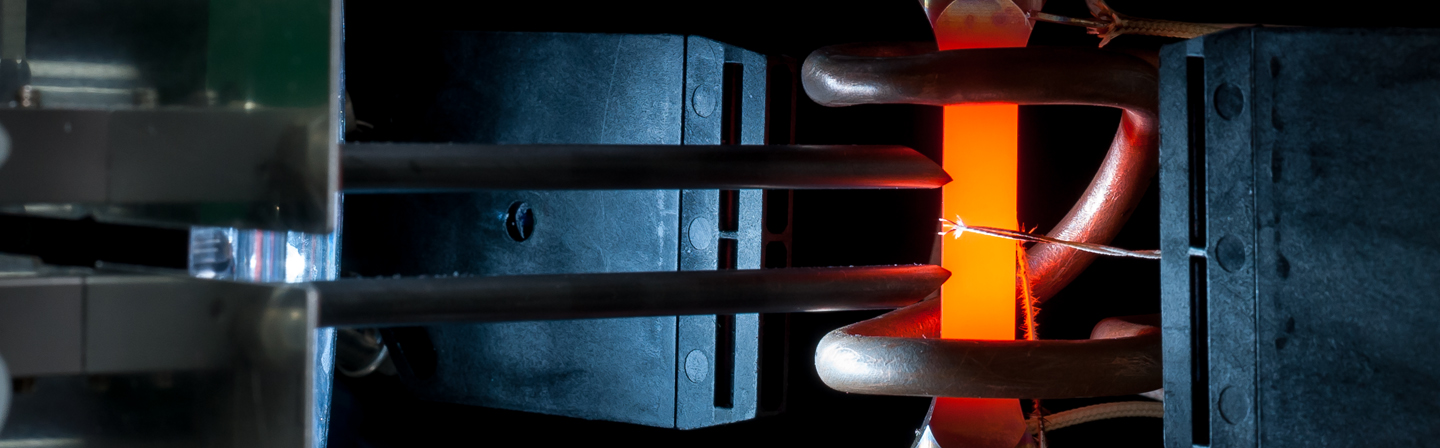

Components in combustion engines, stationary gas turbines, jet engines, power plant technology and system construction are exposed to high thermal and mechanical loads during operation, often over long operating periods. We support manufacturers and operators of components under thermo-mechanical stress in optimization and the design process to ensure safe operation.

Our core competences are generation, analysis and digital management of material data, development, calibration and validation of models based on sound material mechanics for deformation and lifetime analyses and the development of innovative evaluation concepts and software tools for components under thermomechanical loads.

In current and future research projects, we will be developing our methods and concepts further so that they can be integrated into monitoring systems based on real operating data streams, for example, or used to determine component failure probabilities stochastically. We see our contribution, in particular, in the development of material models which, for example, are able to deal with microstructural features and defects caused by processing and, on that basis, allow predictions to be made about the development of damage and probability of failure.

- Characterization and modeling of metals under thermal and mechanical loads at temperatures ranging from -180 °C to over 1000 °C. This includes, in particular, (C)LCF, TMF, overlapping LCF/HCF and TMF/HCF experiments, high-cycle thermo-shock tests including with overlapping low-cycle fatigue loading and creep fatigue experiments.

- Completion of crack development tests under isothermal and anti-isothermal conditions with an (alternating current) potential probe and/or optical methods, short crack propagation measurements using the replica technique

- Completion of warm tension tests, SSRT and pressure tests, relaxation tests and (short-term) creep tests

- Conception, construction and design calculations for special test devices and test bodies similar to components and completion of those tests.

- Option for completion of tests under inert gas or high vacuum

- Explanation of deformation and damage mechanisms in wrought and cast alloys and alloys made by additive manufacturing

- Adaptation of deformation models for LCF, TMF creep and creep fatigue

- Adaptation and development of lifetime models for LCF, TMF, creep fatigue and creep

- Adaptation and development of crack propagation models for LCF, TMF, creep fatigue and creep

- Provision and development of and training in the application of software tools for lifetime assessment of components

- Development of knowledge databases for the above experiments and models

Contact us! Together we'll find a customized solution for the challenges you face.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM