Solarthermal power plants: degradation of materials in molten salts

Driven by the long-term need of utilization of fluctuating regenerative energy resources Fraunhofer IWM invests in the development of methods for assessment and qualification of materials to be used in the molten salt environment of high temperature storage systems of solar power plants (TES thermal energy storage, CSP concentrated solar power plants).

Molten salts have been widely used in the industry, for example as baths of molten chloride salt mixtures for alloying surface treatments or as fluoride salts for the purification of metal surfaces. More recently molten nitrate and nitrite mixtures have been becoming more attractive due to their application as heat transfer fluid (HTF) and thermal storage for the power industry.

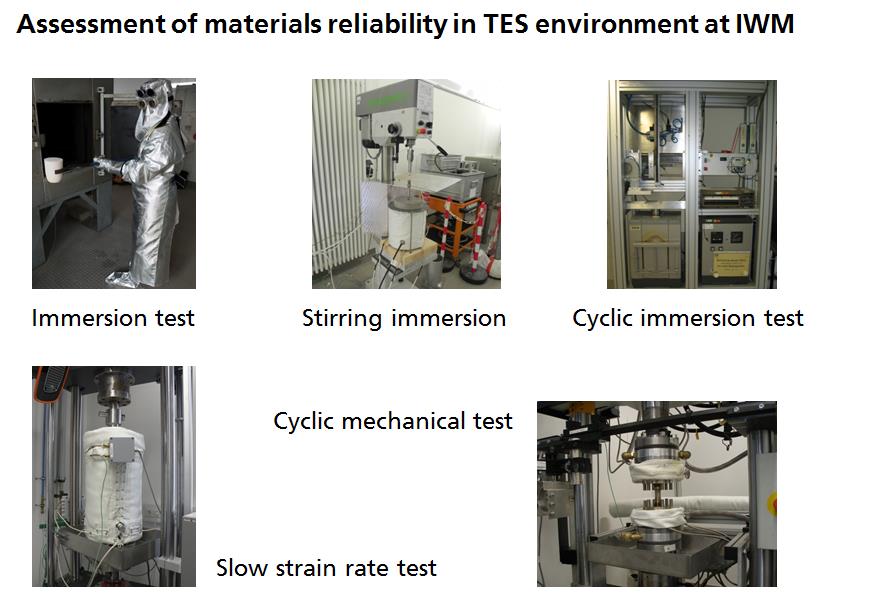

For the optimization of cost-efficiency and reliability of high temperature storage and piping systems for molten salts, comprehensive material characterization and assessment are needed. In the field of heat exchangers the appearance of complex and cyclic thermal-mechanical stresses under the chemical influence of the molten salts can cause a critical degradation of the material resulting in failure of the system. These loads can be simulated in the laboratory with suitable testing techniques and materials can be certified for these conditions of use.

Fraunhofer IWM has qualified and experienced staff (physicists, engineers and chemists) for the study of the degradation mechanisms, the material selection and optimization, the development of protective systems and the evaluation of life time prediction methods.

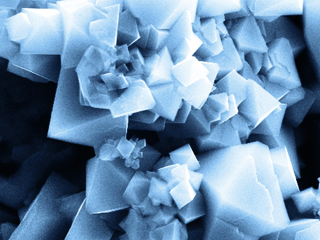

- Comprehensive microstructure and surface analysis by means of optical and electron microscopy, element analysis, EBSD (Electron backscatter diffraction) and X-Ray diffraction (analysis of phases and internal stresses)

- Static corrosion tests to evaluate the corrosion rates and identify the degradation mechanisms

- Corrosion investigations in flowing molten salt

- Slow strain rate tests (SSRT - CERT) i.e. mechanical loading with low strain rate in molten salt environments to separate and quantify the amount of corrosion and stress corrosion cracking occurring in the raw material

- Mechanical fatigue tests with superimposed corrosive stress due to molten salt

- Cyclical thermal corrosive stress

- Development and testing of protective layers

Publications and additional links

- Mallco, A.; Fernandez, A. G.; Preußner, J.; Portillo, C., Corrosion and mechanical assessment in LiNO3 molten salt as thermal energy storage material in CSP plants, in Proc. of ISES Solar World Congress 2019 and IEA SHC International Conference on Solar Heating and Cooling for Buildings and Industry 2019; Cardemil, J.M.; Guthrie, K.; Ruther, R. (Eds.); International Solar Energy Society, Freiburg (2020) 1158-1167 Link

- Preußner, J.; Peiffer, W.; Piedra, E.; Oeser, S.; Tandler, M.; von Hartrott, P.; Maier, G.; Long-term material tests in liquid molten salts; in Proc. of 8th International Conference on Advances in Materials Technology for Fossil Power Plants 2016; Parker, J.; Shingledecker, J.; Siefert, J. (Eds.); ASM International, Materials Park, OH, USA (2016) 1128-1139 Link

- Gurr, M.; Bau, S.; Burmeister, F.; Wirth, M.; Piedra-Gonzales, E.; Krebser, K.; Preußner, J.; Pfeiffer, W., Investigation of the corrosion behavior of NiVAl multilayer coatings in hot salt melts; Surface and Coatings Technology 279 (2015) 101-111 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM