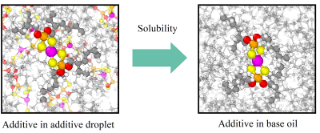

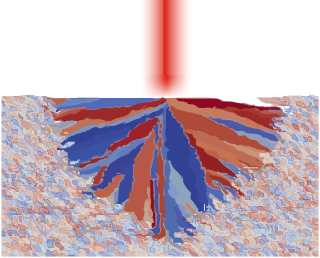

Many tribological systems are operated at their load limits for reasons of efficiency. Lubrication gaps are becoming narrower and lubricating films must withstand greater loads. For the reliable design of such systems, development and construction depend on precise calculation methods. However, conventional calculation approaches fail when it comes to so-called boundary lubrication. Prof. Michael Moseler and Dr. Kerstin Falk from the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg have succeeded in clarifying the mechanisms of boundary lubrication and making them predictable. This opens a path to new design possibilities for high-performance tribosystems. They present their groundbreaking approach in a renowned scientific journal.

more info Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM