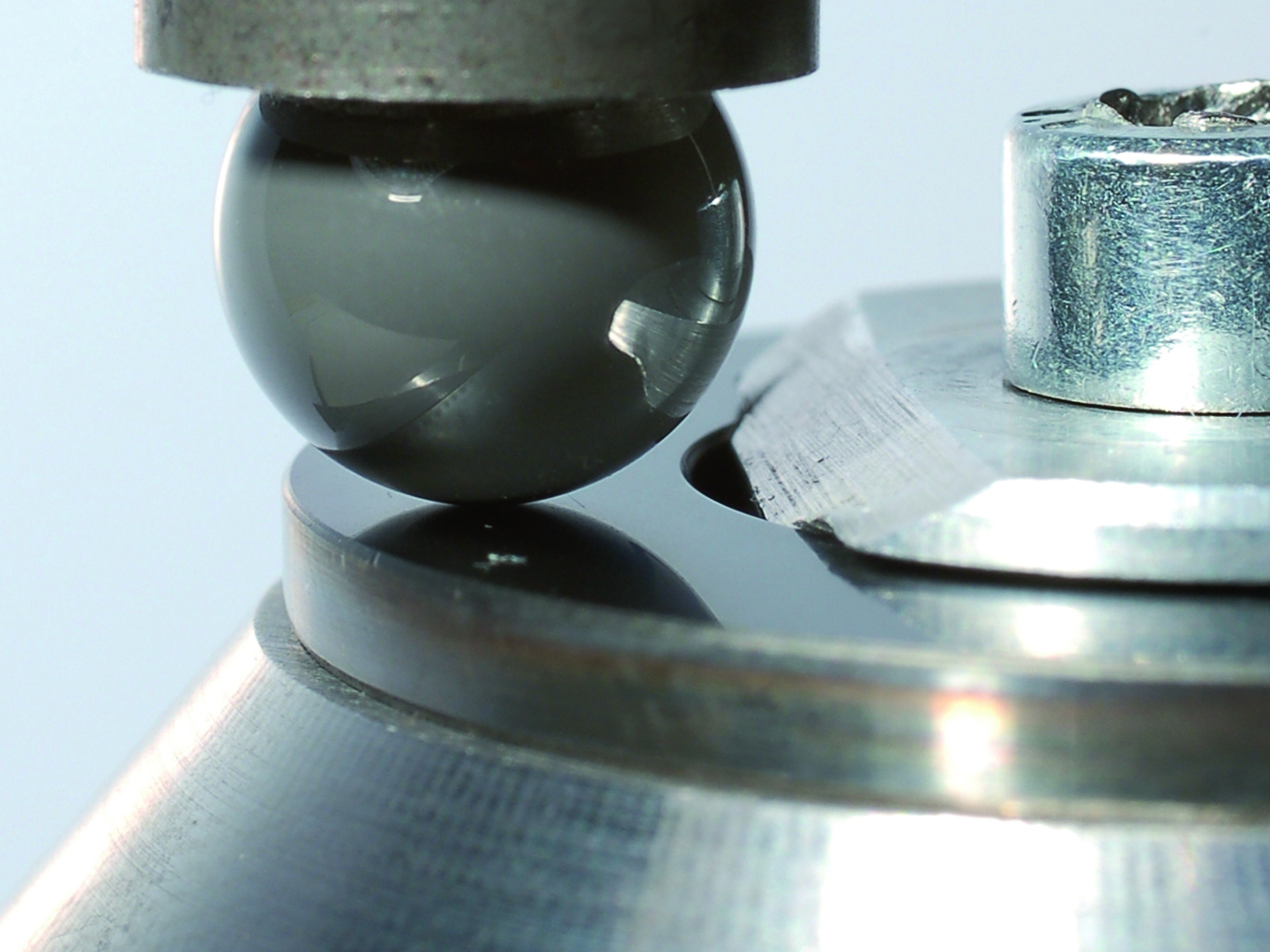

The fundamental processes determining the service life and efficiency of friction contacts in technical components play out in the first hundred nanometers below the surface. Friction and wear are highly dynamic non-balanced operations, which are subject to intensive feedback. These processes can be better understood in model experiments through a combination of in-situ tribometry, surface physical and chemical measurements, and simulations.

Understanding fundamental mechanisms in tribocontact

Publications

- Joerger, A.; Morstein, C.; Dienwiebel, M. Albers, A., A numerical approach for the determination of graphite deformation behaviour by using microtribological pressure tests, Wear 476 (2021) Art. 203652, 9 Seiten Link

- Mangolini, F.; Li, Z.; Marcus, M.A.; Schneider, R.; Dienwiebel, M., Quantification of the carbon bonding state in amorphous carbon materials: A comparison between EELS and NEXAFS measurements, Carbon 173 (2021) 557-564 Link

- Savio, D.; Hamann, J.; Romero, P. A.; Klingshirn, C.; Bactavatchalou, R.; Dienwiebel, M.; Moseler, M., Multiscale friction simulation of dry polymer contacts: Reaching experimental length scales by coupling molecular dynamics and contact mechanics, Tribology Letters 69/2 (2021) Art. 70, 16 Seiten Link

- Scherge, M.; Stoll, M.; Moseler, M., On the influence of microtopography on the sliding performance of cross country skis, Frontiers in Mechanical Engineering 7 (2021) Art. 659995, 10 Seiten Link

- Stoyanov, P.; Merz, R.; Stricker, M.; Kopnarski, M.; Dienwiebel, M., Achieving ultra-low friction with diamond/metal systems in extreme environments, Materials 14/14 (2021) Art. 3791, 9 Seiten Link

- Takagi, K.; Hashamova, E.; Dienwiebel, M.; Mine, Y.; Takashima, K., Correlation of wear behaviour and microstructural evolution in Mg–Zn–Y alloys with long-period stacking ordered phase, Wear 482-483 (2021) Art. 203983

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM