Seeking new materials – reducing the dependence on critical raw materials

There is great demand in the industry for designing new materials, driven by stricter technical requirements and amended economic and legal framework conditions. As a result, new materials need to have tailored physical properties and be compatible with existing production processes. Furthermore, they should be based on cheap raw materials and only contain a few - or ideally zero - critical elements. Dependence on fluctuating raw material prices and delivery monopolies should also be reduced.

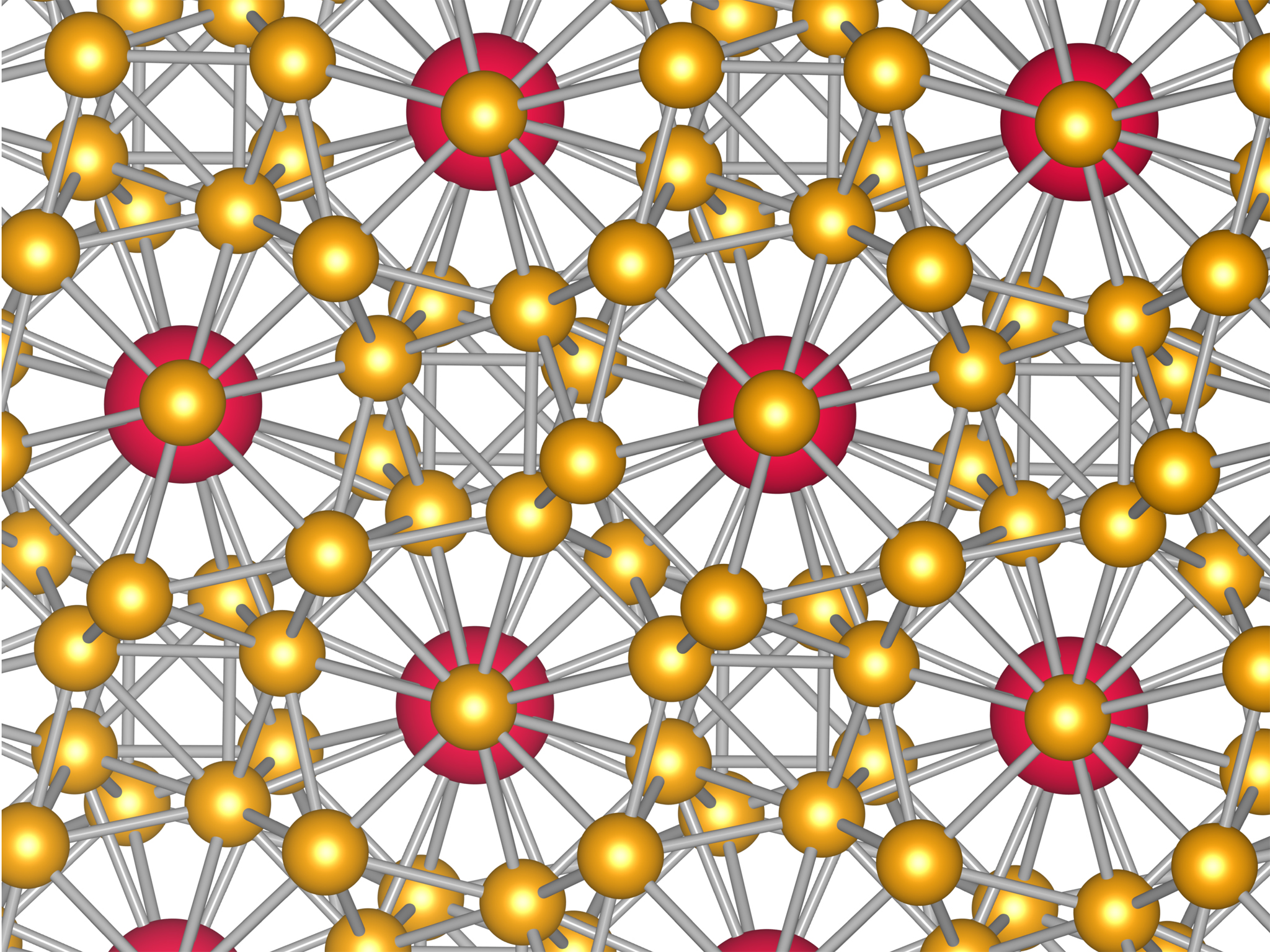

Virtual testing of material properties with high-throughput screening

The development of new materials in principle faces the needs of expensive and time-consuming experimental synthesis. At this point, a computational high-throughput screening approach is employed to speed up the development of novel materials. New simulation methods and growing computer capacities allow for a large number of structures and compositions to be virtually generated and predictions of their properties to be made. A large variety of options can be tested systematically and acted out in an efficient manner. The basis for this is a database in which the theoretical materials are stored. Data analysis algorithms make use of this database in order to adjust and improve the search direction on a permanent basis. Materials with promising properties can then subsequently be investigated in more detail and in a second step be experimentally synthesized.

High-throughput technologies are suited to a large range of material classes. Screening methods are used at the Fraunhofer IWM, for example when looking for new hard magnets that only contain low amounts of rare earth metals - or no rare earth metals at all. Other material systems investigated include electrically conductible and corrosion-resistant materials for fossil fuel cells and materials for battery technologies.

Analysis of large quantities of data with machine learning and data mining

Machine learning offers further options to virtually detect new, attractive material structures. The large quantities of data generated by the computational high-throughput screening are post-processed using data mining algorithms. As a result, we extract the relations between crystal structures and composition (input) and physical properties (output) in the constantly growing IWM material library. We use this knowledge to uncover general trends and to find new phases with desired properties.

By using this combination of physical (high-throughput screening) and statistical (machine learning, data mining) methods, we have a comprehensive skills basis in material informatics and are able to engage in finding the desired structure-property relationships and material designs in a goal-oriented and efficient manner.

Publications

- Guillon, O.; Elsässer, C.; Gutfleisch, O.; Janek, J.; Korte-Kerzel, S.; Raabe, D.; Volkert, C.A., Manipulation of matter by electric and magnetic fields: Toward novel synthesis and processing routes of inorganic materials, materialstoday 21/5 (2018) 527-53 Link

- Körner, W.; Krugel, G.; Urban, D.F.; Elsässer, C., Screening of rare-earth-lean intermetallic 1-11 and 1-11-X compounds of YNi9In2-type for hard-magnetic applications, Scripta Materialia 154 (2018) 295-299 Link

- Möller, J.; Körner, W.; Krugel, G.; Urban, D.F.; Elsässer, C., Compositional optimization of hard-magnetic phases with machine-learning models, Acta Materialia 153 (2018) 53-61 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM