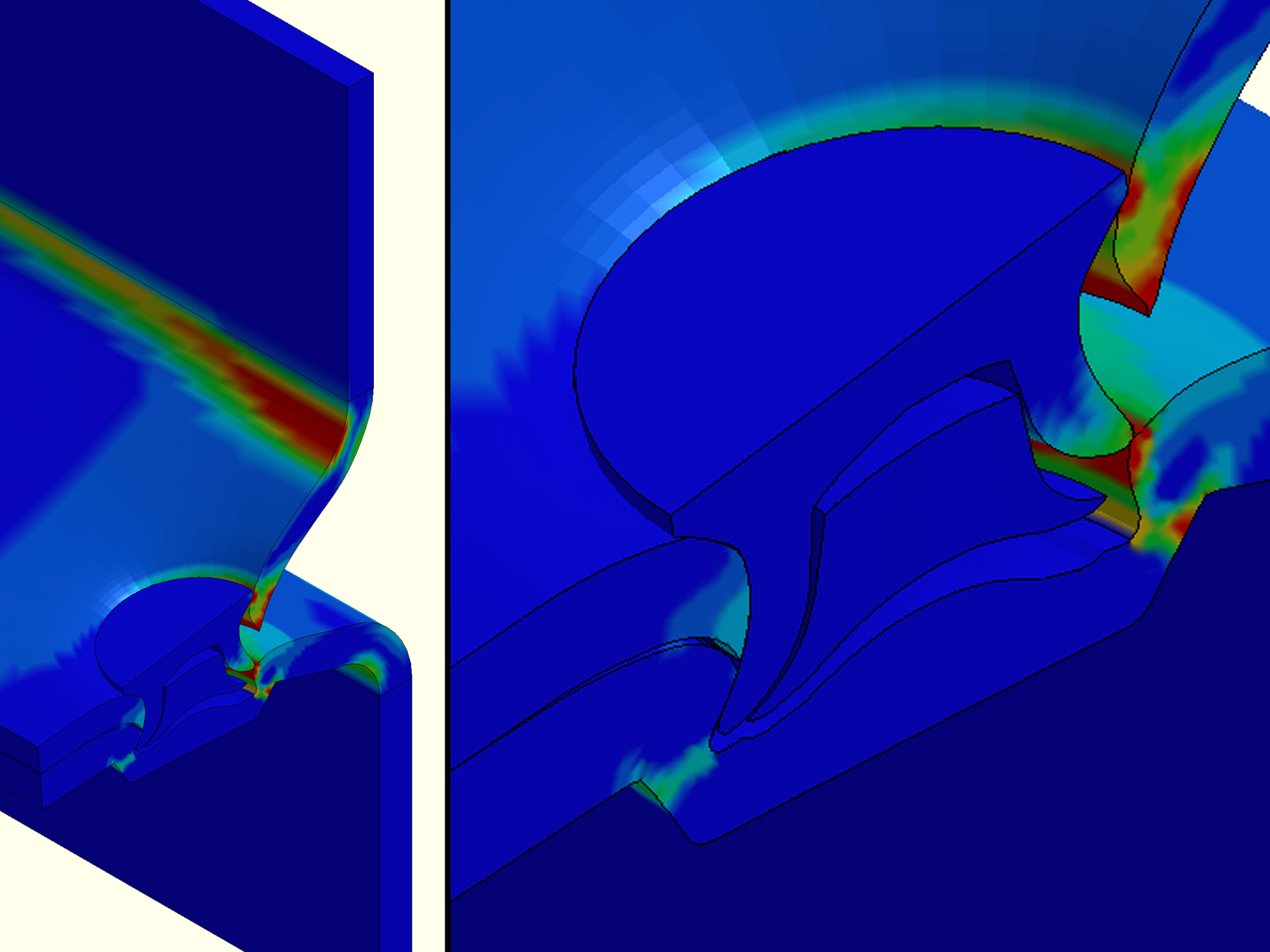

Mechanical joining techniques have the advantage that they can be used to join different types of materials in a safe process, without the negative effects of heat on the material properties. A number of mechanical joining techniques, such as semi-tubular punch rivets and direct screw joints are therefore used on multi-material mixes in automobile manufacturing. Until now, there has been a lack of simulation models and characteristic joint data that would make the use of these joining techniques more effective, particularly in crash-relevant areas, with the aid of predictions about the load-bearing behavior of these joints under crash conditions. A substitute model for semi-tubular punch rivets was therefore refined, a method for determining its parameters has been identified and validated through component trial simulations.

Advanced substitute model for punch rivets joints

Publications

- Bähr, P.; Sommer, S.; Unruh, E.; Meschut, G., Modeling of component failure due to notch effects in press-hardened steel caused by mechanical and thermo-mechanical joints under crash load, in Proc. of 13th European LS-DYNA Conference 2021; DYNAmore GmbH, Stuttgart (2021) Art. 013; 10 Seiten Link

- Sommer, S.; Rochel, P.; Guenther, M.; Herfert, D.; Meschut, G.; Giese, P., Crash simulation of mechanical joints with automatically determined model parameters based on test results and prediction algorithms, in Proc. of 15th International LS-DYNA® Users Conference 2018; DYNAmore GmbH (Hrsg.); DYNAmore GmbH, Stuttgart (2018) 14 Seiten Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM