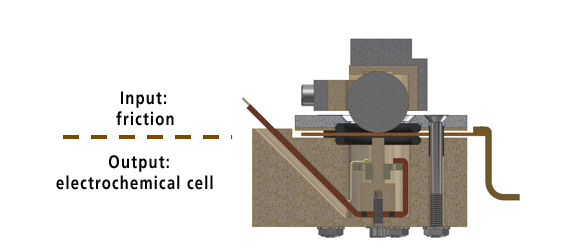

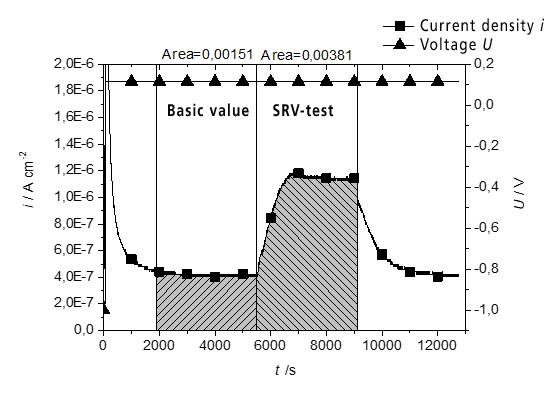

Chemical processes take place in all tribological contacts. Since chemical interactions are generally characterized by bonding electrons and electron transitions, it is possible to influence them by means of electrical voltages. Electrochemical methods can be used to investigate and influence chemical reactions in tribological contacts.

On this page:

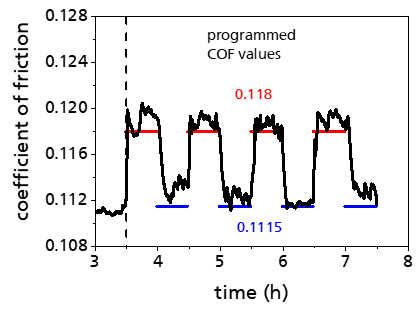

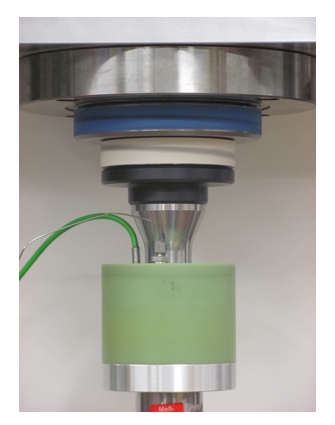

Lubricant development, triboelectrochemical wear protection / Electrically conductive lubricants, control of friction, water-based lubrication, plain bearing optimization

Hydrogen embrittlement (rolling bearings, lubricant development)

Optimization of rolling bearings, E-mobility

Current development topics

- Lubricant development for rolling bearings

- Electrically conductive lubricants

- Ionic liquids as lubricant additive

- Measurement of breakdown voltage in rolling bearings

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM