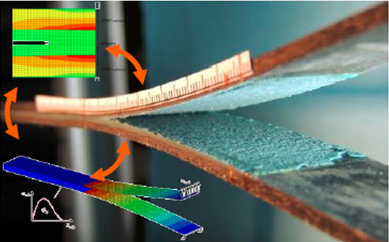

By avoiding local stress concentrations, adhesive joining can offer advantages in light-weight structures compared to mechanical fasteners. For a reliable component design the load carrying capacity and failure behavior of the adhesive joint has to be understood and simulation methods are required to be as accurate and as efficient as possible. Cohesive zone models are often used to meet both requirements. In order to provide the necessary material behavior data, scientists at the Fraunhofer IWM experimentally characterize adhesive joints, which can account for additional effects such as loading rate, temperature and humidity. Local details may furthermore be studied by high-discretization continuum mechanics modeling of the deformation and damage behavior, which can be included into the component modeling.

Gall, M.; Hohe, J.; Simulation of adhesive joints in composite structures with efficient virtual determination of cohesive zone parameters, in Tagungsband NAFEMS-Seminar »Simulation von Composites - Eine geschlossene Prozesskette?«; NAFEMS Deutschland GmbH (Ed.); NAFEMS Deutschland GmbH, Bernau am Chiemsee (2014) 324-332 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM