Microstructure clarification and assessment

Microstructures are responsible for the properties of raw materials and therefore for the properties of the resulting components which are produced. Microstructures are adjusted using different manufacturing steps. In use, they can change both positively and negatively. We uncover the relationships between the microstructure and the raw materials’ properties and use this information to gain optimized material properties - for example with regard to mechanical properties, long-term behavior, life expectancy, abrasive properties, corrosion properties, etc.). By using computer simulations, we can predict microstructures and assess them with regard to the reliability, safety and lifetime of components. Building on this, we develop concepts to design components and optimize manufacturing processes.

We measure and analyze the material's microstructures and determine the structural properties. To do so, we use:

- Microscopy (optical, scanning electron microscope)

- Hardness measurement (core hardness, hardness profiles, hardness mapping)

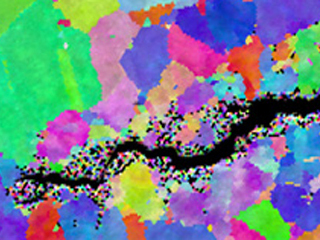

- Measuring of the local crystallographic texture (e.g. locally by electron backscatter diffraction (EBSD), macroscopically by or X-ray diffraction (XRD))

- Quantitative structure determination (optical, ESBD, XRD)

- Glow discharge optical emission spectroscopy (GDOES) to measure the chemical composition

- X-ray and partly destructive residual stress analyses

We model and prepare predictions on the raw material’s microstructure. To do so, we calculate changes to structure in manufacturing processes and use programs such as Thermocalc, Dictra, Matcalc and Sysweld as well as our own codes.

We assess the raw material’s microstructure with regard to

- Corrosion

- Stress corrosion cracking

- Strength properties

- Deformability

- Functionality of abrasion and corrosion protective coatings

- Heat treatment

- Process-caused strain hardening

- Security of weld joins

- Surface quality after component processing or coating

- Failure mechanisms and interaction between crack growth and microstructure

- Hydrogen influences (diffusion behavior, fatigue, brittleness)

Publications

- Janarthanam, H.; Sommer, S.; Carl, E.- R.; Preußner, J.; Huberth, F., Numerical prediction of damage in punching process using shear modified Gurson model, in Proc. of 4th European Steel Technology and Application Days; Stahlinstitut VDEh, Düsseldorf (2019) 11 Seiten

- Beckmann, C.; Kennerknecht, T.; Preußner, J.; Farajian, M.; Luke, M.; Hohe, J., Micromechanical investigation and numerical simulation of fatigue crack formation in welded joints, Engineering Fracture Mechanics 198 (2018) 142-157 Link

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM