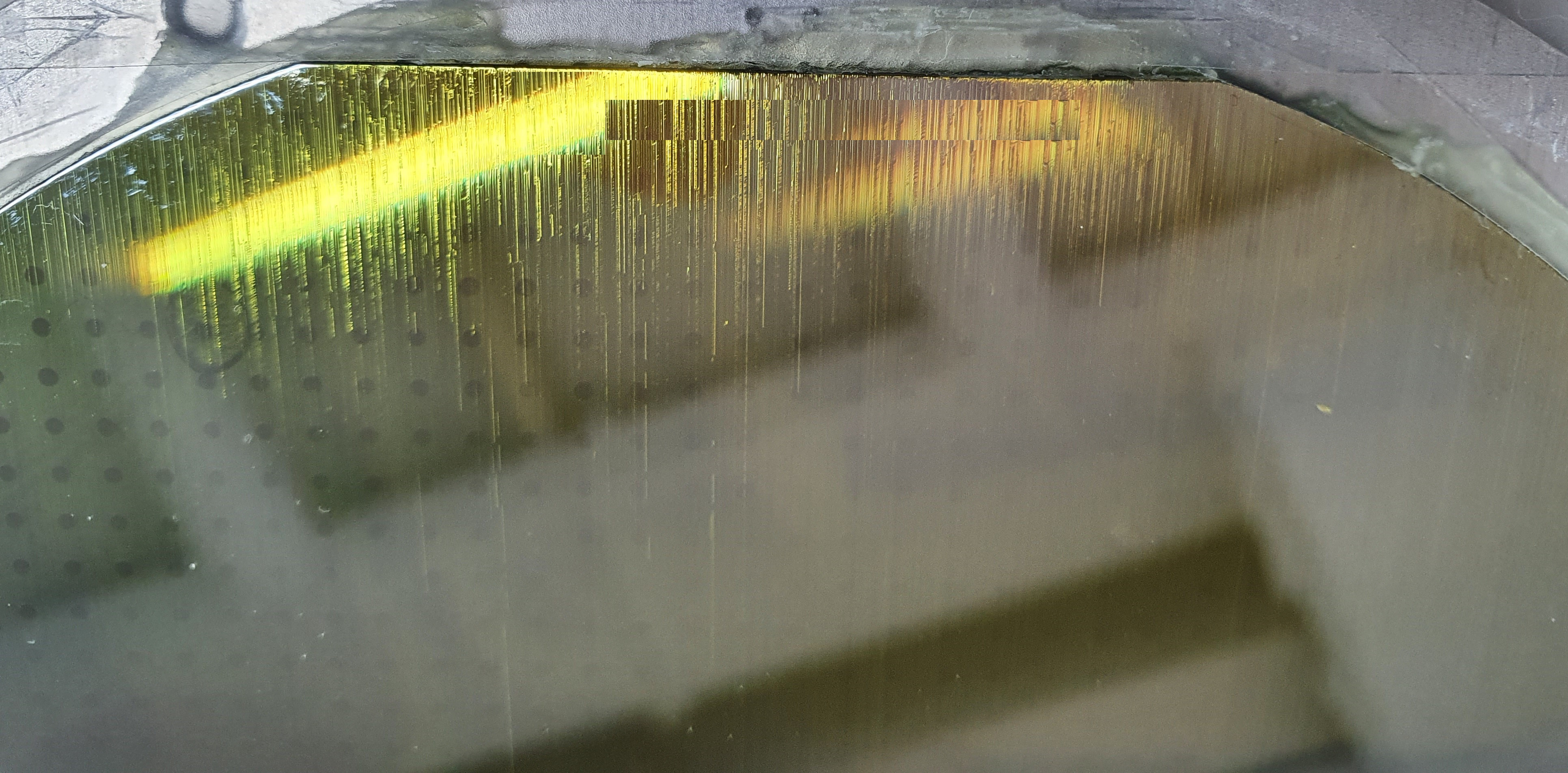

We analyze and characterize damage and material failure in glasses, ceramics and semiconductors. In doing so, we identify weak points in the material or (glass) composite. By looking for relevant stresses along the entire process chain as far as damages during use, we can identify critical manufacturing steps and recommend effective measures to avoid the causes of material failure.

With our results, we provide solutions for new processes and products as well as well-founded assessments of economic efficiency and feasibility in industrial applications. We ultimately ensure the safety of both manufacturers and users in the production, processing and use of glass and glass components.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM