Effect of heat treatment and aging on the microstructure and lifetime of Alloy 617B

In recently completed research projects, investigations of high-temperature deformation and lifetime under cyclical loading of Alloy 617B have been carried out for various material states. By means of accompanying metallographic analyses, a better understanding has been gained of the microstructure and the way it changes as a result of thermal and thermomechanical loading. An extensive study of the literature on Alloy 617B and numerous other studies under isothermal and anti-isothermal cyclical loads and creep fatigue and pure creep loads also contribute to a better understanding of the material. On the basis of this improved understanding, it has been possible to extend the existing material models to include microstructure terms and adapt their parameters in such a way that, based on the starting condition of the material and load, the deformation and lifetime of Alloy 617B can be predicted with good accuracy.

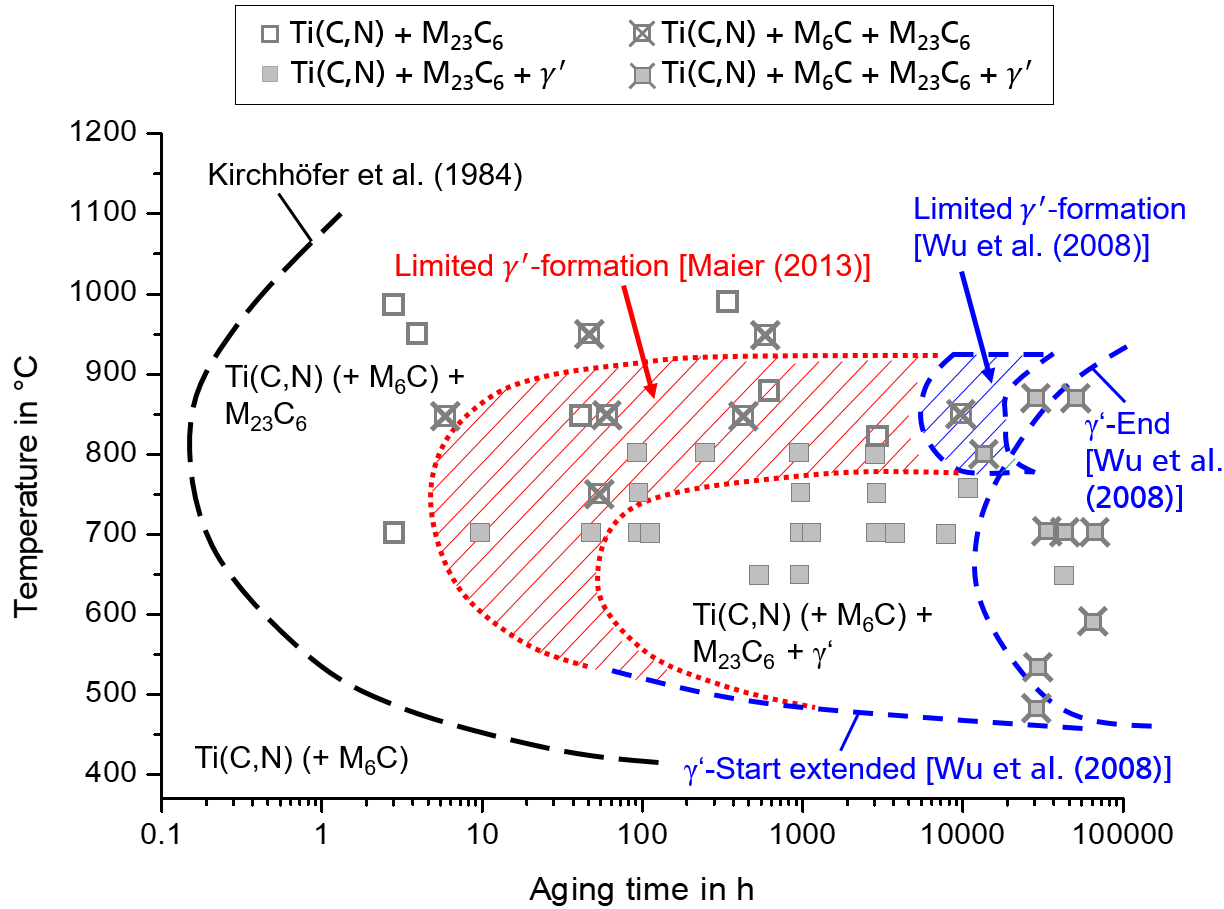

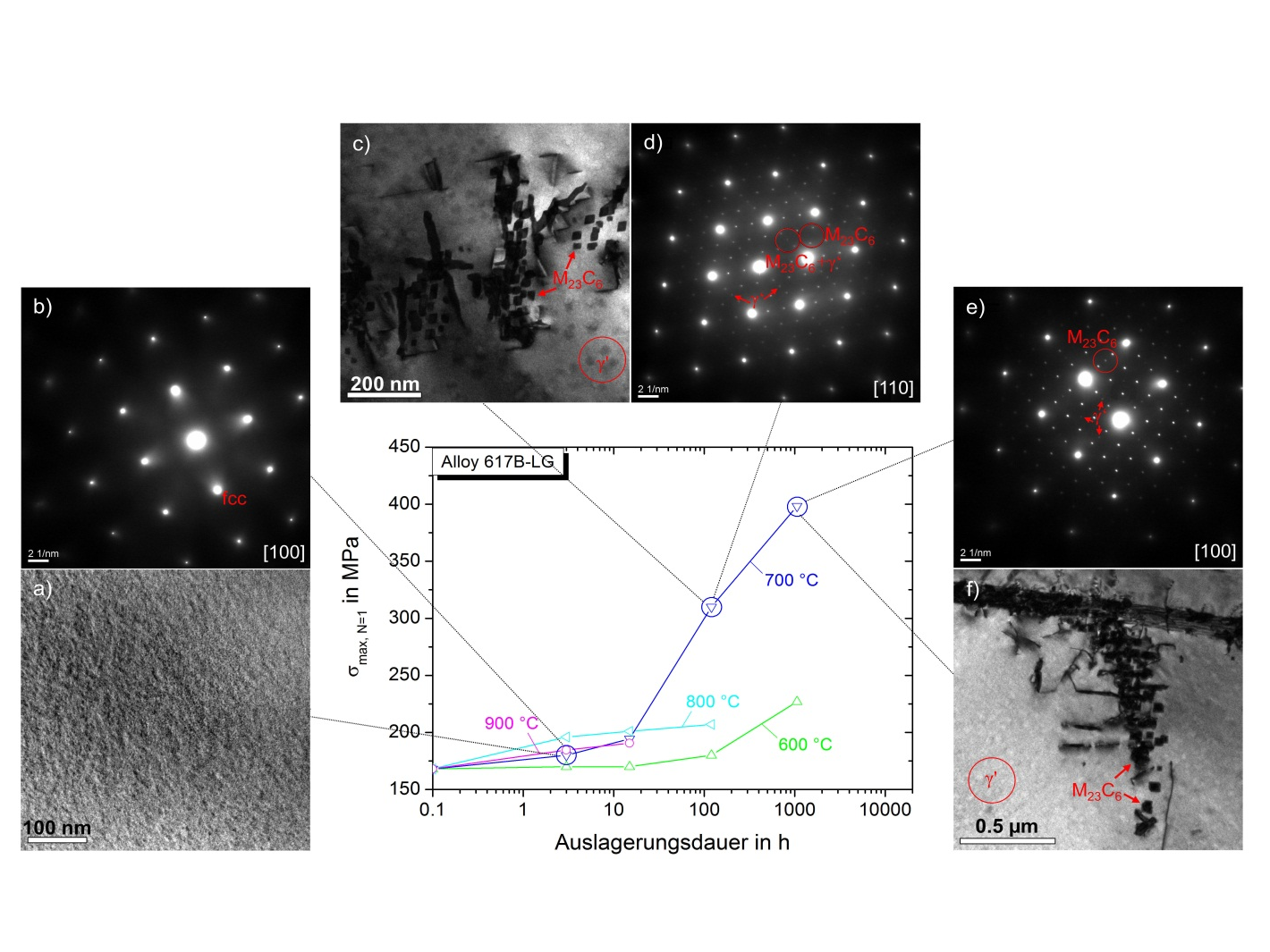

Figure 1 shows an example of how the microstructure and thus the strength of a solution-annealed starting material changes as a result of thermal aging at 600°C to 900°C for periods of up to 1080 h. The first significant changes in the behavior of the material in a cyclical test become evident after an aging period of 120 h. In TEM images of the sample aged for 120 h at 700°C, clear precipitations can be detected even in the bright area (Fig. 1c). In the diffraction image in the direction of the [110] zone axis of a representative area in the inside of the grain, alongside the reflexes of the y-matrix, reflexes of M23C6 and precipitations in the γ’ phase are evident (Fig. 1d). The carbides are mostly precipitated at displacements, while the precipitations in the γ’ phase are distributed homogeneously in the grain. After an aging period of 1080 h at 700°C, coarser precipitations can be found at twin boundaries in comparison to aging for 120 h. The strength has grown further in comparison to 120 h and has increased by more than double in comparison to the solution-annealed starting condition. In contrast to aging at 700°C, although the strength increases continuously during aging at 600°C, 800°C and 900°C, it is significantly less pronounced with increasing aging time.

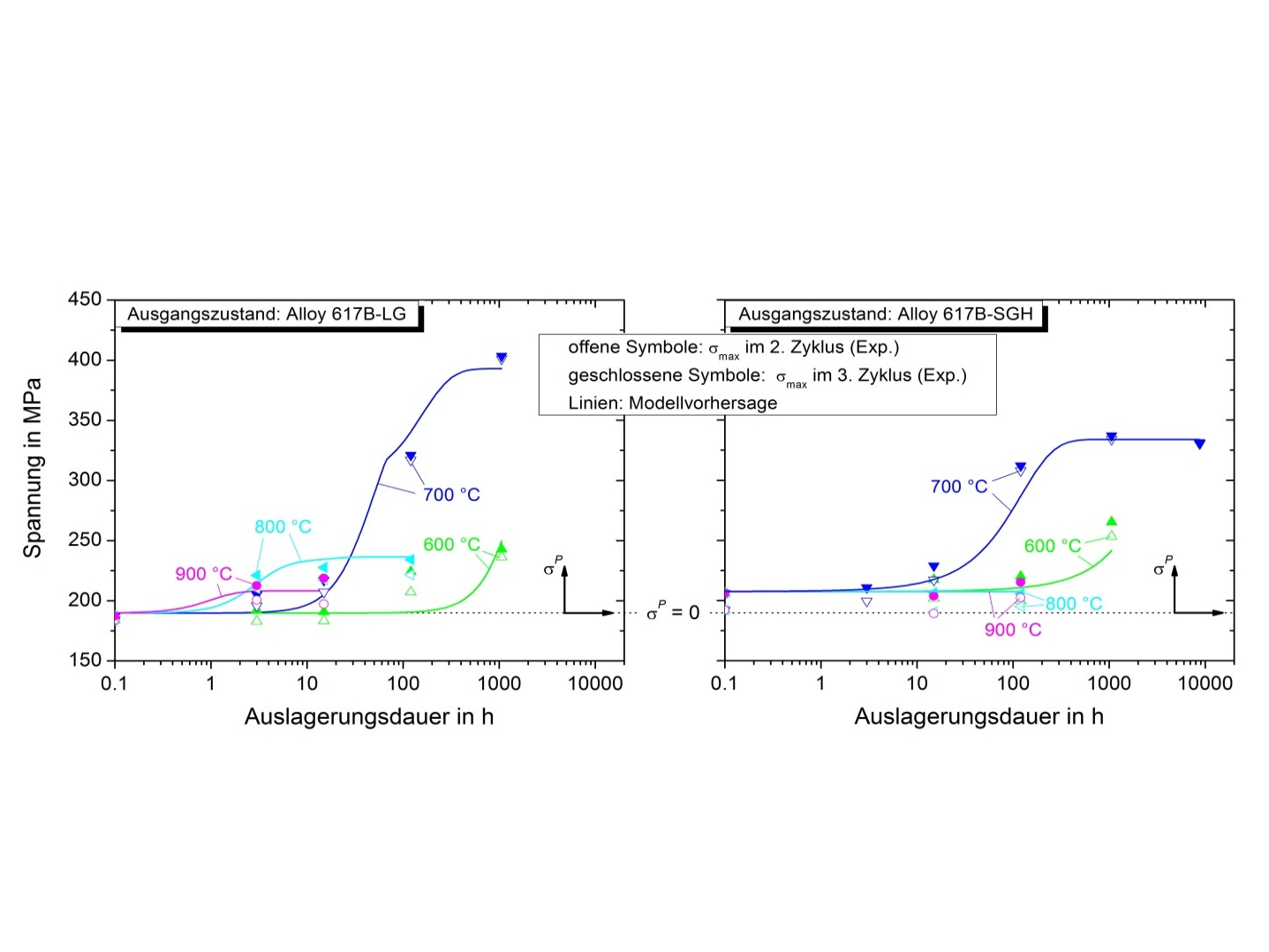

Figure 2 shows the measured development of maximum stresses at the beginning of cyclical tests according to various thermal aging periods, together with the predictions for the precipitation model after parameter adaptation. The stress increase resulting from microstructural changes after thermal aging of Alloy 617B can be described clearly by the precipitation model.

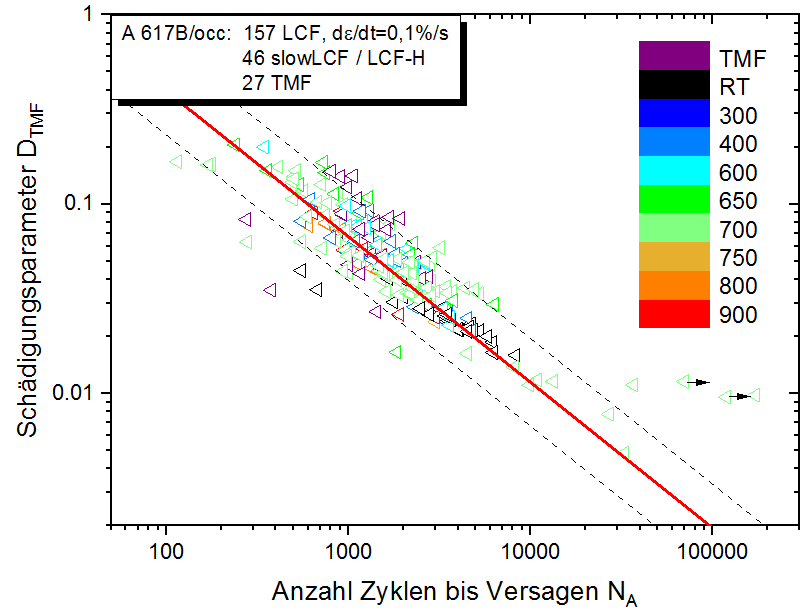

Figure 3 shows a lifetime diagram for Alloy 617B based on the DTMF damage parameter developed at the Fraunhofer IWM. The diagram includes more than 200 LCF tests, some with slow load rates, with and without holding times at temperatures between room temperature and 900°C, and 27 TMF tests on Alloy 617B/occ representing various batches, product forms and heat treatments. All tests can be described with the DTMF lifetime model within a factor 2 scatter band, with the exception of one or two tests.

Back to Assessment of Materials and Lifetime Concepts Highlights

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM