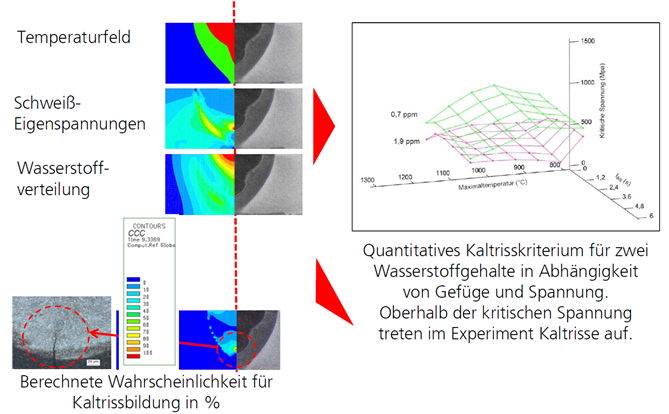

Calculation of the cold crack risk

Using numerical calculation of structures, residual stresses and hydrogen diffusion during welding, it is possible to predict the cold crack resistance of complex components. This approach means that users of thermal manufacturing processes, e.g. welding and heat treatment, are able to take account of cold crack reliability even in the development phase of structures. This is achieved by coupling numerical simulation with experimentally determined risk criteria, taking process-typical loads into account.

The figure shows a laser-welded pipe made of high-strength steel for which the cold crack probability has been calculated from the numerical simulation of the temperature field, residual welding stresses and local hydrogen distribution. The basis for the assessment was a quantitative cold crack criterion that was determined for the high-strength steel by a new experimental method. (AiF project with LFT at BTU Cottbus)

Back to Assessment of Materials and Lifetime Concepts Highlights

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM