Automated large-area grid measurements of residual stresses via the cosα-method

Plastic deformation of a component induces internal mechanical stresses that are referred to as residual stresses. With knowledge of the local distribution of residual stresses, it is possible to adapt production and treatment processes to ensure a safer and more economical operation.

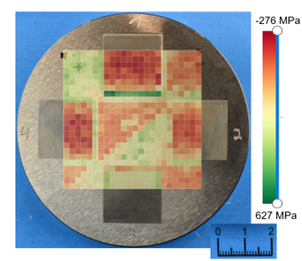

Using the novel cosα-method, residual stresses can now be measured punctually with a mobile diffractometer within one minute. In connection with a robot arm, this results in the possibility to conduct large mappings with a small step size for the first time. The mappings can be conducted on various materials, such as metals (steel, aluminium) or ceramics. Under consideration of the analyzed state of residual stresses, lifetime assessments can be carried out to calculate actual operating times for a component in defined operating conditions.

With this method, new possibilities for various industries are now emerging. For example, gradients of residual stresses in welded joints can be examined in detail or surfaces of additively manufactured components can be assessed.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM