Innovative tool for the future of materials testing

Fast, non-contact strain measurement method for materials subjected to high thermal and mechanical loads

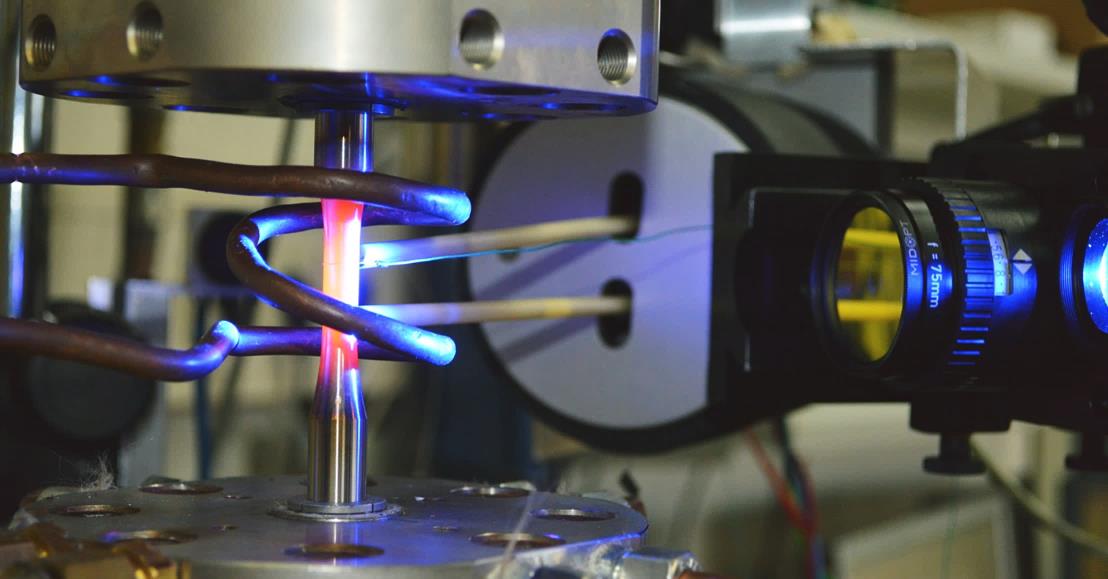

(July 17, 2017) Materials for light construction and high-temperature applications first have to be qualified before use in order to be able to utilize them to their full potential. The fatigue tests necessary for this purpose can now be performed with a newly developed optical strain measurement system with significantly faster test frequencies without the use of conventional, contacting measurement systems which lead to unwanted damage to test specimens. The versatile process developed by the Fraunhofer IWM and IPM combines the advantages of previous optical and mechanical measuring methods.

High-performance materials improve the function and extend the application range of machines and systems, such as in light construction and high-temperature applications in the automotive industry, in power plants or in aircraft engines. However, components based on high-performance materials have to be qualified in each case in order to ensure the resilience and safety of the subsequent product. In view of the mechanical properties and the service life behavior, they occur, for example, with high-frequency fatigue tests under a cyclic, recurrent load. These measurements place high demands on the measuring speed of the strain measurement systems which are used. Now, researchers at the Fraunhofer Institute for Mechanics of Materials IWM and the Fraunhofer Institute for Physical Measurement Techniques IPM have succeeded in increasing by a factor of ten the measuring speed for the non-contact strain measurement as part of fatigue tests.

No-contact, mark-free strain measurement

Optical strain measurement systems are non-contact and therefore do not affect the sample; this advantage already applies to conventional optical systems. Their biggest disadvantage, though, is their slow image processing speed, which limits the measuring and, therefore, the control frequency. Such high measuring rates are a prerequisite for the optical strain control with which scientists at both institutes currently are intensively working. High control and measuring frequencies have so far only been achieved in fatigue tests with tactile extensometers: the pressure force of the extensometer rods which is necessary in this process can lead to unwanted damage to the sample and thus, to a falsification of the measurement results, particularly under test conditions in the area of the material load limit. The new optical measuring system uses fast, modern image processing technologies for the first time to combine the advantages of tactile and optical extensometers: fast, high-resolution cameras reliably record surface structures, even on polished samples, and use these structures as natural markers in image processing. This eliminates the complex sample preparation for the application of artificial markers.

Evaluation with 1000 Hz

By parallelized image evaluation on graphics cards, the strain can be measured without contact at more than 1000 Hz – previously with optical systems, only measuring rates up to 100 Hz were possible. The measuring accuracy of the new Fraunhofer strain measurement system corresponds to Class 0.5 pursuant to DIN ISO 9513. The size of the image field can be adapted to the test task; in the future, the real-time evaluation will also allow expansion-controlled experiments in the micro- and macro-range. The optical measurement system will also offer the possibility of further image processing analyses. The will, for example, enable the damage development to be analyzed both in real-time or subsequently. In this way, project partners receive higher accuracy measurement data for even more precise predictions of the component lifetime.

Contact

Stefan Eckmann

Phone +49 761 5142-335

Send E-mail

Uwe Strohmeier

Phone +49 761 5142-342

Send E-mail

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM